Table of Contents 4

Table of Contents

Preface.............................................................................................................................................................................................................................................................. 2

Change history................................................................................................................................................................................................................................................. 3

Table of Contents............................................................................................................................................................................................................................................ 4

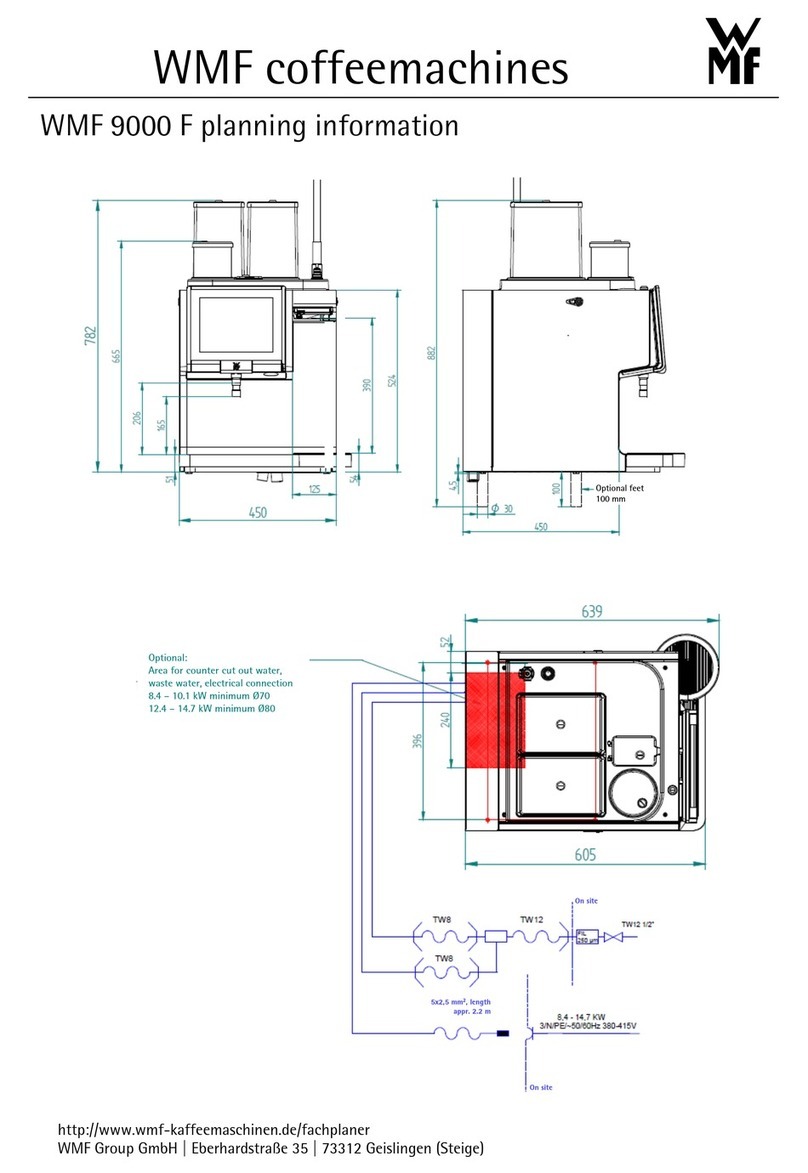

1Installation and commissioning........................................................................................................................................................................................................ 6

1.1Customers on-site connection requirements .........................................................................................................................................................................................................................6

1.2Hardware connection and preparatory work .........................................................................................................................................................................................................................7

1.2.1General tasks......................................................................................................................................................................................................................................................................................7

1.2.2Recommended water filter ...........................................................................................................................................................................................................................................................7

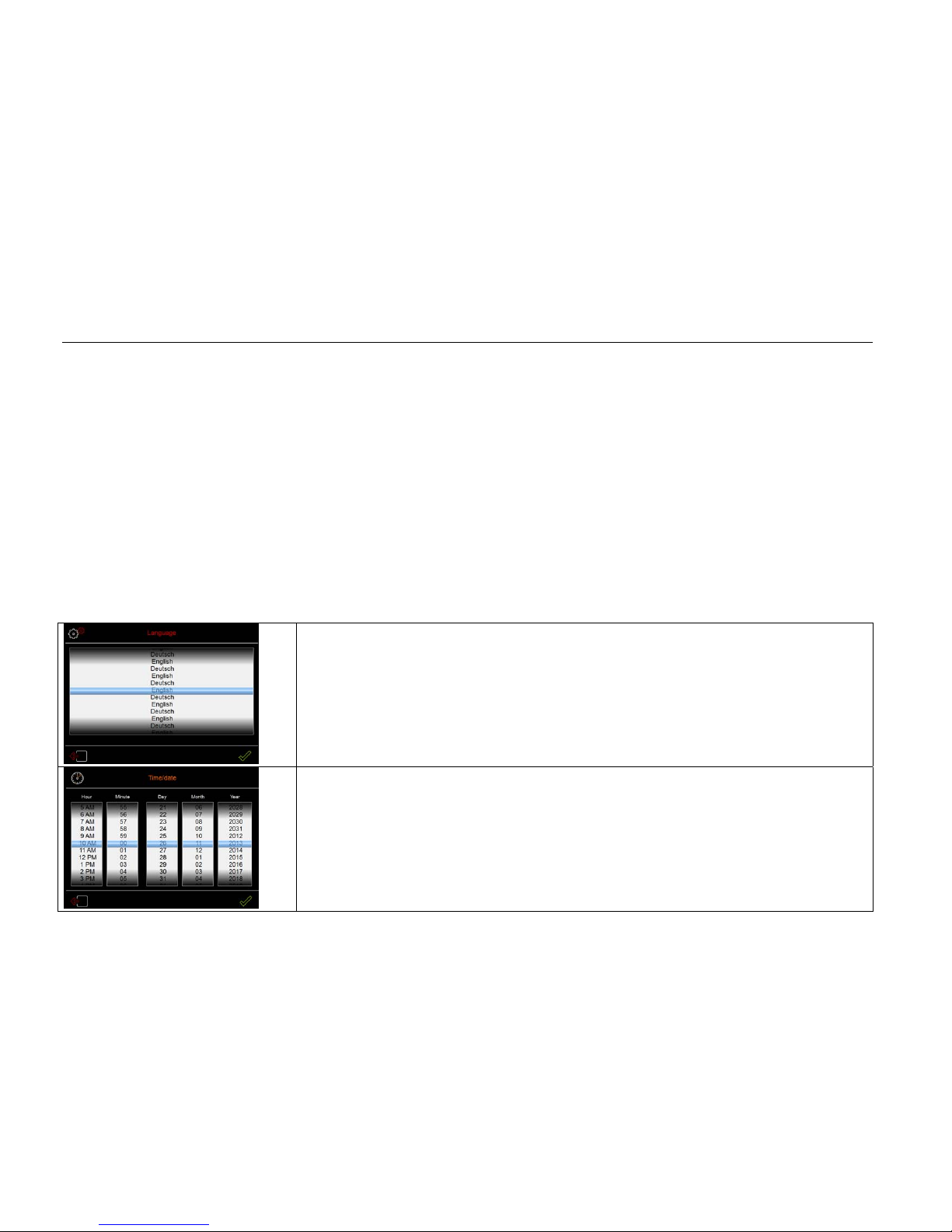

1.3Initial start-up with the aid of the technical information ................................................................................................................................................................................................8

1.3.1Goal of the technician information...........................................................................................................................................................................................................................................8

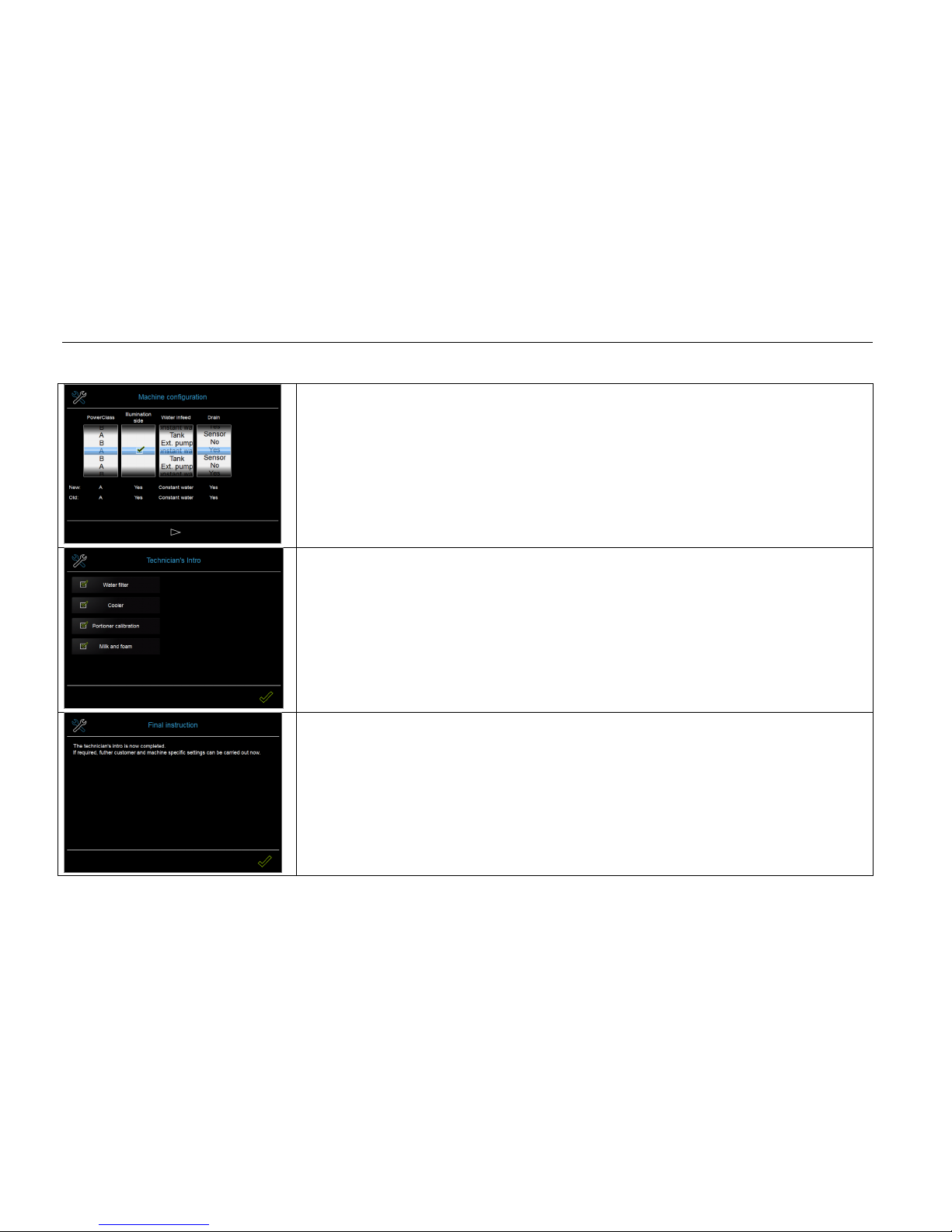

1.3.2Workflow, technician info: ...........................................................................................................................................................................................................................................................8

2Service................................................................................................................................................................................................................................................ 11

2.1Brewer............................................................................................................................................................................................................................................................................................... 11

2.2Distance between angle sensor and brewer spindle (magnet) ...................................................................................................................................................................................... 12

2.3Espresso pump................................................................................................................................................................................................................................................................................14

2.4Pressure reducer setting ............................................................................................................................................................................................................................................................. 15

2.5Grinders ............................................................................................................................................................................................................................................................................................ 16

2.5.1Grinder - grinding degree setting ........................................................................................................................................................................................................................................... 16

2.6Power stage..................................................................................................................................................................................................................................................................................... 17

2.7Front panel ...................................................................................................................................................................................................................................................................................... 17