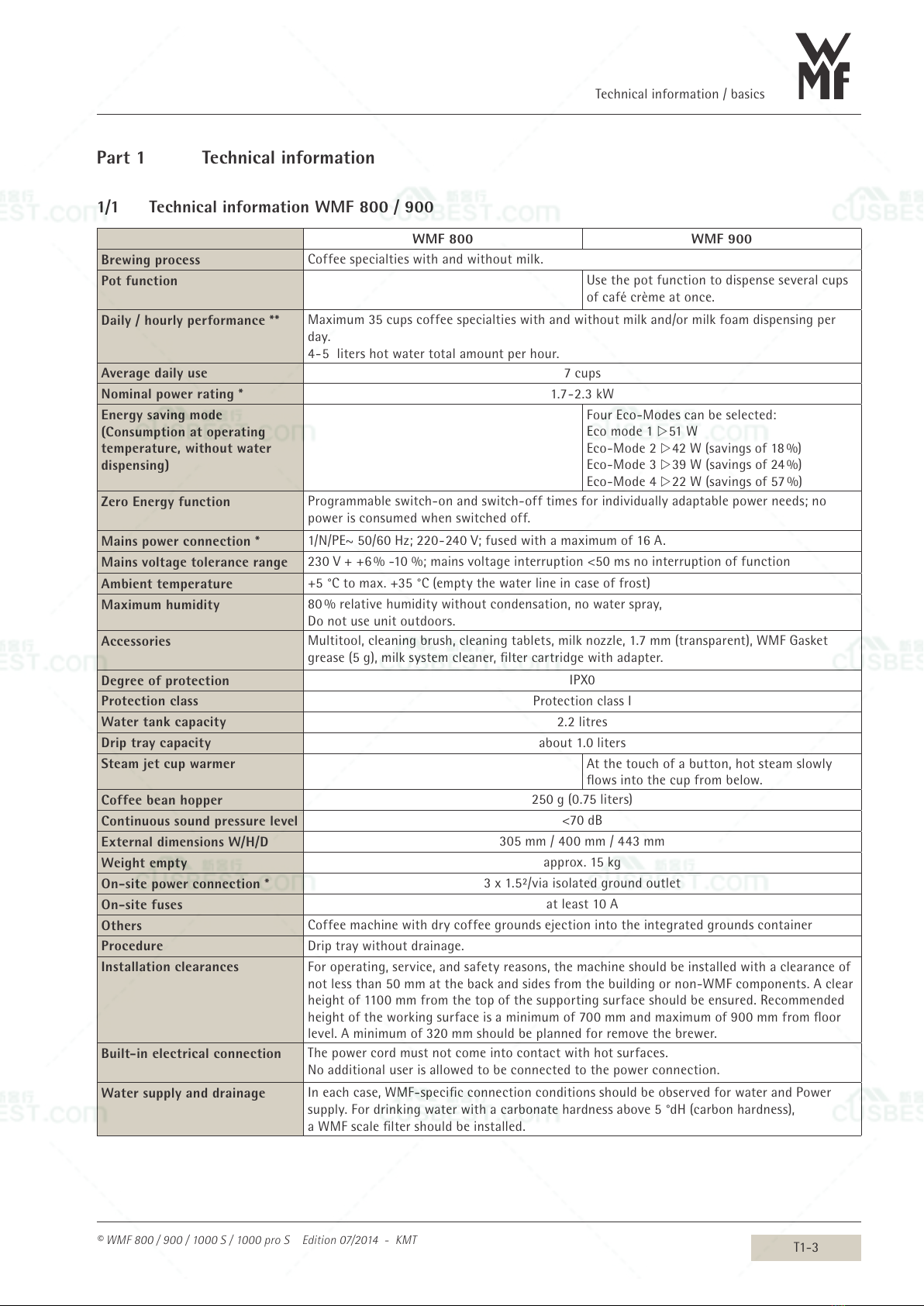

General information

© WMF800 / 900 / 1000S / 1000proS Edition 07/2014 - KMT

T1-4

1/2 Technical information WMF1000S / 1000proS

WMF1000S WMF1000proS

Brewing process Coffeespecialtieswithandwithoutmilk.

Pot function Usethepotfunctiontodispenseseveralcupsofcafécrèmeatonce.

Daily/hourly performance** Maximum50cupscoffeespecialtieswithandwithoutmilkand/ormilkfoamdispensingper

day.4-5litershotwatertotalamountperhour.

Average daily use 10cups

Nominal power rating * 1.7-2.3kW

Energy saving mode

(Consumption at operating

temperature, without water

dispensing)

FourEco-Modescanbeselected:

Ecomode1w47W

Eco-Mode2w42W(savingsof11%)

Eco-Mode3w39W(savingsof17%)

Eco-Mode4w22W(savingsof53%)

Zero Energy function Programmableswitch-onandswitch-offtimesforindividuallyadaptablepowerneeds;no

powerisconsumedwhenswitchedoff.

Mains power connection * 1/N/PE~50/60Hz;240V;fusedwithamaximumof16A.

Mains voltage tolerance range 230V+6%-10%;mainsvoltageinterruption<50msnointerruptionoffunction.

Ambient temperature +5°Ctomax.+35°C(emptythewaterlineincaseoffrost)

Maximum humidity 80%relativehumiditywithoutcondensation,nowaterspray,donotuseunitoutdoors.

Accessories Multitool,smallcleaningbrushes,cleaningtablets,gasketgrease(5g)

Transparentmilknozzleforunrefrigerated

milk,steamnozzle(sparepart),airintakepipe

withcap(sparepart)

Milklance,cleaningbrushforthemilklance

Degree of protection IPX0

Protection class ProtectionclassI

Water tank capacity 2.8litres

Drip tray capacity about1.0liters

Steam jet cup warmer Atthetouchofabutton,hotsteamslowlyowsintothecupfrombelow.

Coffee bean hopper 280g(withoptionalcontainerexpansion600g)

Continuous sound pressure level <70dB

External dimensions W/H/D 380mm/407mm(withoptionalcontainerexpansion459mm)/449mm

Weight empty approx.19kg

On-site power connection* 3x1.5²/viaisolatedgroundoutlet

On-site fuses atleast10A

Others Coffeemachinewithdrycoffeegroundsejectionintotheintegratedgroundscontainer

Procedure Driptraywithoutdrainage.

Installation clearances Foroperating,service,andsafetyreasons,themachineshouldbeinstalledwithaclearanceof

notlessthan50mmatthebackandsidesfromthebuildingornon-WMFcomponents.Aclear

heightof1,100mmfromthetopofthesupportingsurfaceshouldbeensured.Theheightof

theinstallationsurfaceabovetheoorisatleast850mm.Atleast320mmclearancemust

beprovidedabovethemachineinordertoremovethebrewingunitformaintenanceand

cleaning.

Built-in electrical connection Thepowercordmustnotcomeintocontactwithhotsurfaces.

Noadditionaluserisallowedtobeconnectedtothepowerconnection.

Water supply and drainage Ineachcase,WMF-specicconnectionconditionsshouldbeobservedforwaterandPower

supply.Fordrinkingwaterwithacarbonatehardnessabove5°dH(carbonhardness),

aWMFscaleltershouldbeinstalled.

*Thelocalpowersupplymustbeconstructedaccordingtoapplicablenationalregulations(e.g.VDE0100forGermany).Toimprove

safety,thecoffeemachineshouldbettedwithanFI30mAearthleakagecurrentcircuitbreakercomplyingwithDINVDE0664.

IfthemainsconnectionleadforthiscoffeemachineisdamagedthenitmustbereplacedusinganoriginalWMFsparepart.No

additionaluserisallowedtobeconnectedtothepowerconnection.

**Thegivendaily/hourlyperformanceisaSTANDARDVALUE,which,amongotherthings,isdependentuponthefollowingfactors:

groundcoffeequantity,typeofcoffee,grindingdegree,brewwateramount,waterhardnessandgeneraloperatingstatusofthe

coffeemachine(e.g.scaling,connectionconditions,electricalpower,drinkingwater,drainage,wear,etc.).