ii BMST50doc100919 Table of Contents

Table of Contents Section-Page

SECTION 1 INTRODUCTION 1-1

1.1 About this manual...................................................................................................... 1-1

1.2 Safety......................................................................................................................... 1-2

Blade handling safety

Machine operation safety

Decal meaning

1.3 Major Components .................................................................................................... 1-5

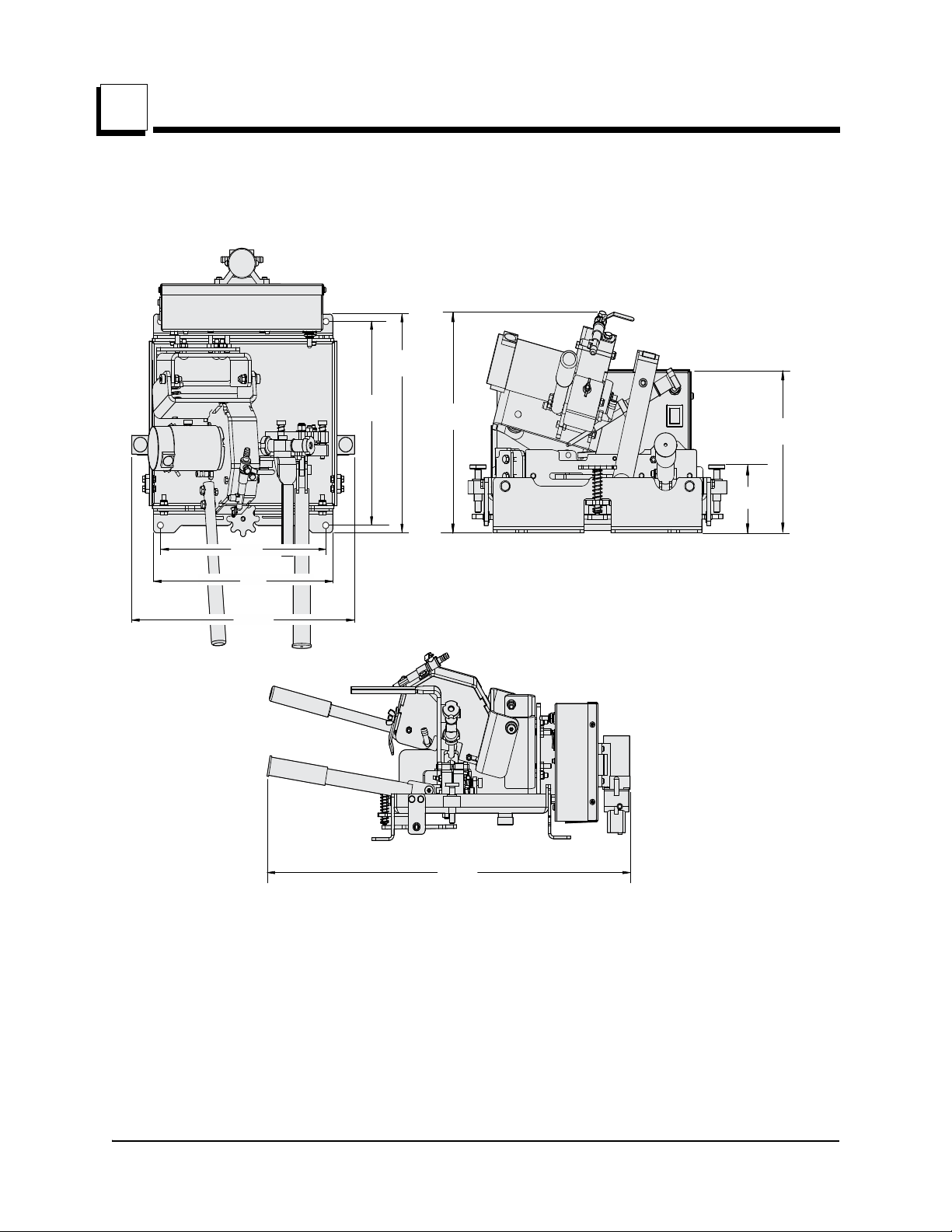

1.4 Dimensions and Specifications.................................................................................. 1-6

1.5 Getting Service .......................................................................................................... 1-7

General Contact Information

Wood-Mizer Locations

SECTION 2 SET UP 2-1

2.1 Items required but NOT included.............................................................................. 2-1

2.2 Items included ........................................................................................................... 2-2

2.3 Install the lubrication pump....................................................................................... 2-3

2.4 Mount the base unit ................................................................................................... 2-4

2.5 Install the drain pipe .................................................................................................. 2-4

2.6 Install the operators handles ...................................................................................... 2-5

2.7 Mount the blade supports .......................................................................................... 2-5

2.8 Install grinding wheel................................................................................................ 2-7

2.9 Power cord................................................................................................................. 2-7

2.10 Calibrate the set gauge............................................................................................... 2-8

SECTION 3 OPERATION 3-1

3.1 Blade introduction ..................................................................................................... 3-1

3.2 Rejecting blades......................................................................................................... 3-2

3.3 Install the grinding wheel .......................................................................................... 3-2

3.4 Blade installation....................................................................................................... 3-2

3.5 Sharpening ................................................................................................................ 3-3

Prior to 6/28/2015

After 6/28/2015

3.6 Blade Sharpening Tips ........................................................................................... 3-10

3.7 Deburr the blade after sharpening ........................................................................... 3-10

3.8 Setting the blade ...................................................................................................... 3-10

3.9 Checking the set ...................................................................................................... 3-12

3.10 Quick check of the set ............................................................................................. 3-13