Product

Description

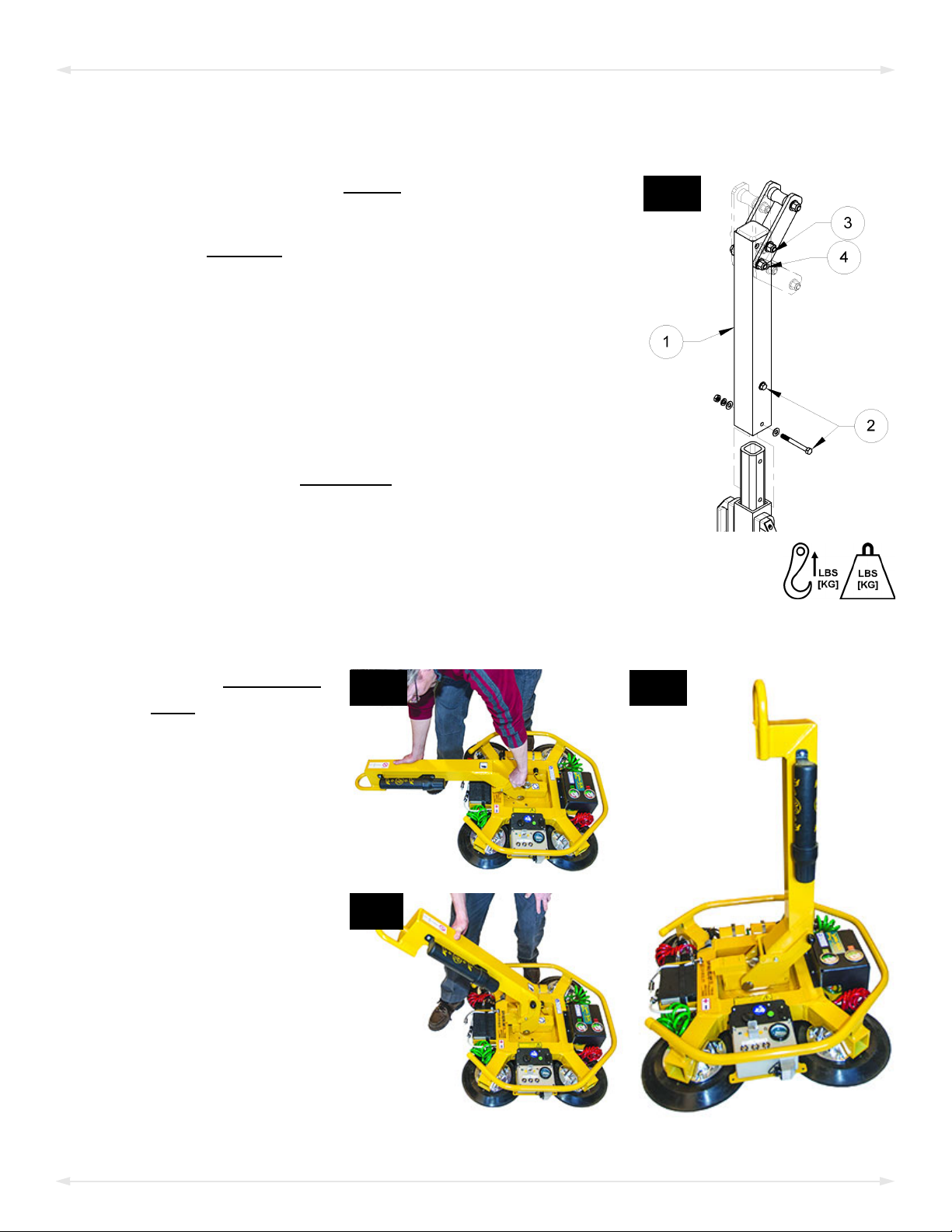

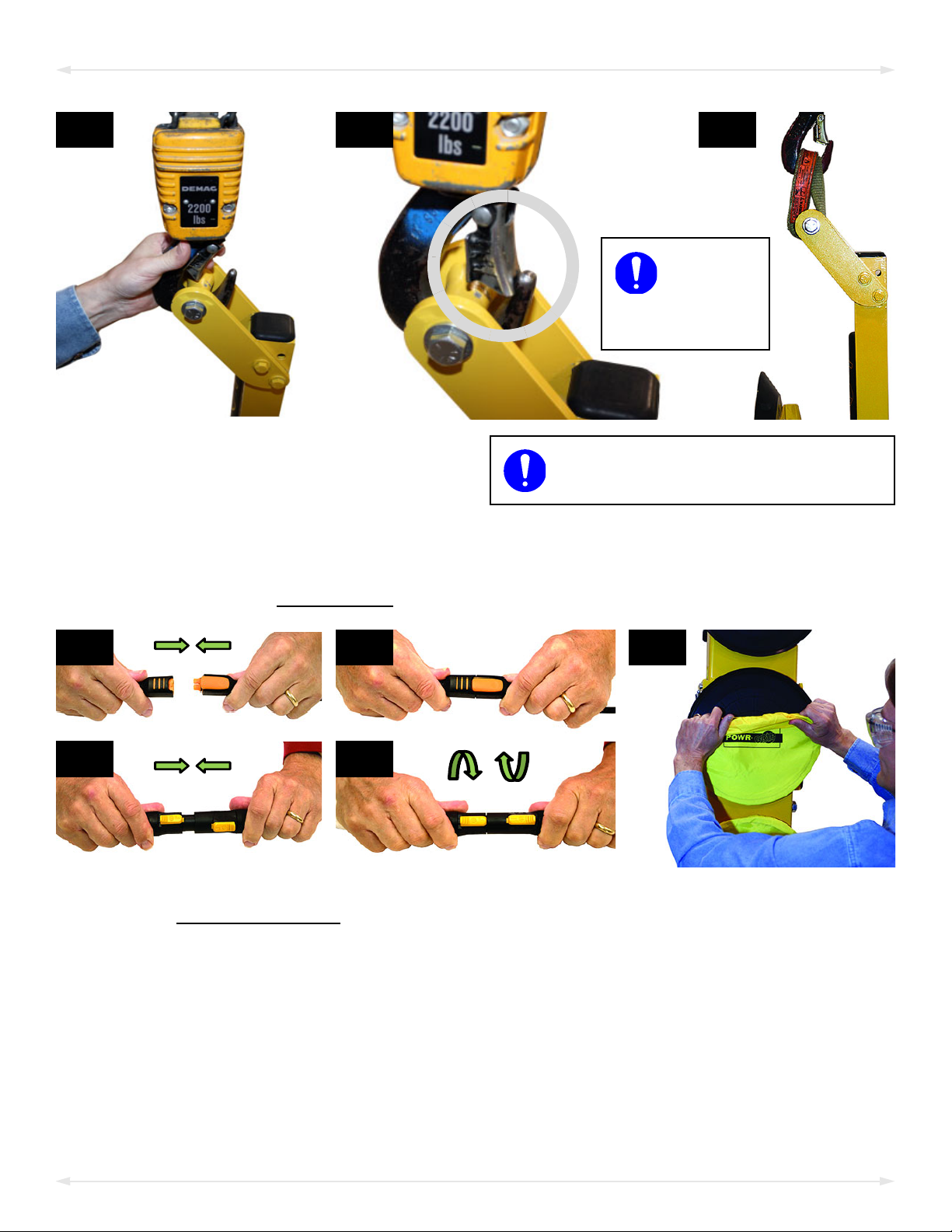

Designed for use with hoisting equipment, MRTALPCH6-DC3 lifters support loads using vacuum and

manipulate loads using manual 180° rotation and mechanically assisted, manual 90° tilt motions.

Model

Number MRTALPCH611LDC3 MRTALPCH610LDC3O MRTALPCH610CDC3O

Vacuum Pads

(6 each, standard rubber1

1...... Available with other rubber compounds for special purposes (see www.WPG.com).

)

11" [28 cm] nom. diameter,

lipped (Model G3370)

10" [25 cm] nom. diameter,

lipped (Model HV11)

10" [25 cm] nom. diameter, con-

cave (Model G0750)

Pad Spread ---------------------------- (to outer edges) ----------------------------

Maximum 79¼" x 12" [201 cm x 30 cm] 78¼" x 11" [199 cm x 28 cm] 77¼" x 10" [196 cm x 25 cm]

Minimum 53¾" x 12" [137 cm x 30 cm] 52¾" x 11" [134 cm x 28 cm] 51¾" x 10" [131 cm x 25 cm]

Maximum

Load Capacity2

2...... The Maximum Load Capacity is rated at a vacuum of 18 Hg [-60 kPa] on clean, smooth, nonporous flat surfaces with a friction coefficient of 1. Pad

compound, load rigidity, strength, surface conditions, overhang, angle, center of gravity and temperature can also affect the lifting capacity. A qualified

person should evaluate the effective lifting capacity for each use (see definition under “Rated Load Test” on page 33).

Per-Pad 184 lbs [83.5 kg] 150 lbs [68.5 kg] 150 lbs [68.5 kg]

Total with 4 Pads 700 lbs [320 kg] 600 lbs [270 kg] 600 lbs [270 kg]

Total with 6 Pads 1,100 lbs [500 kg] 900 lbs [410 kg] 900 lbs [410 kg]

Lifter

Weight 130 lbs [59 kg]

Power

System 12 volts DC, 4.5 amps

Battery

Capacity 7 amp-hours

Rotation

Capability Manual, 180°, with latching at each ¼ turn (when required)

Tilt

Capability

Manual, 90°, with automatic latching in upright position and four-bar tilt linkage that provides mechanical

advantage

Product

Options

Available with Remote Control System – FCC, CE and ICC certified.

See separate instructions about other options.

Operating

Elevation Up to 4,500' [1,370 m]

Operating

Temperatures 32° — 104° F [0° — 40° C]

Service

Life 20,000 lifting cycles, when used and maintained as intended3

3...... Vacuum pads, filter elements and other wear-out items are excluded.

Software

Version Intelli-Grip®7.6

ASME Standard

BTH-1 Design Category "B", Service Class "0" (see www.WPG.com for more information)

Rev 1.0/12-19 MRTALPCH6-DC3(RC): #351253

!!–CE–!! This symbol appears only when a CE Standard is different from other applicable standards. CE requirements are

mandatory in the European Union, but may be optional elsewhere.

SPECIFICATIONS