Rev 5.1/4-21 FLEXR(L)-HV11AIR: #350361

SPECIFICATIONS .....................................................................................3

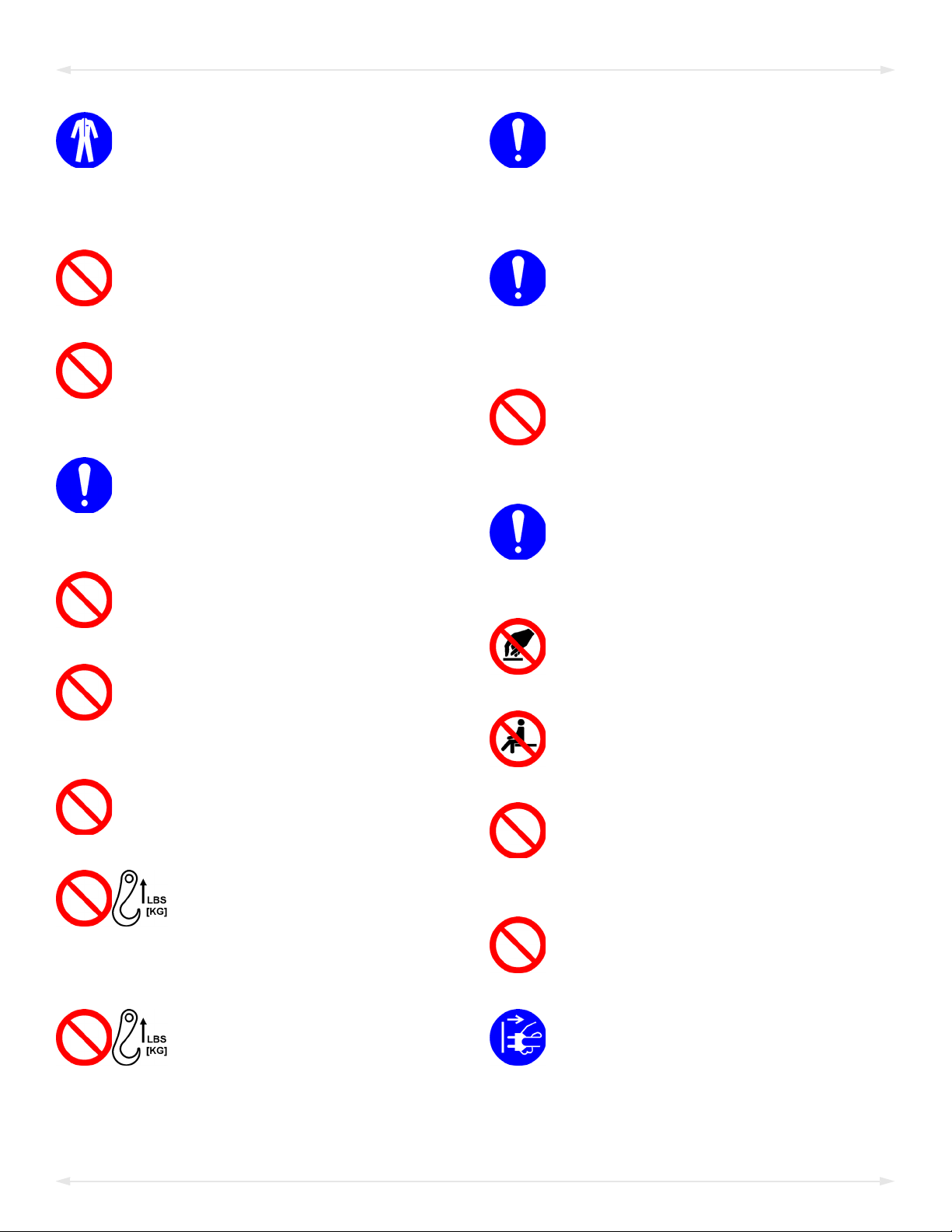

SAFETY...................................................................................................5

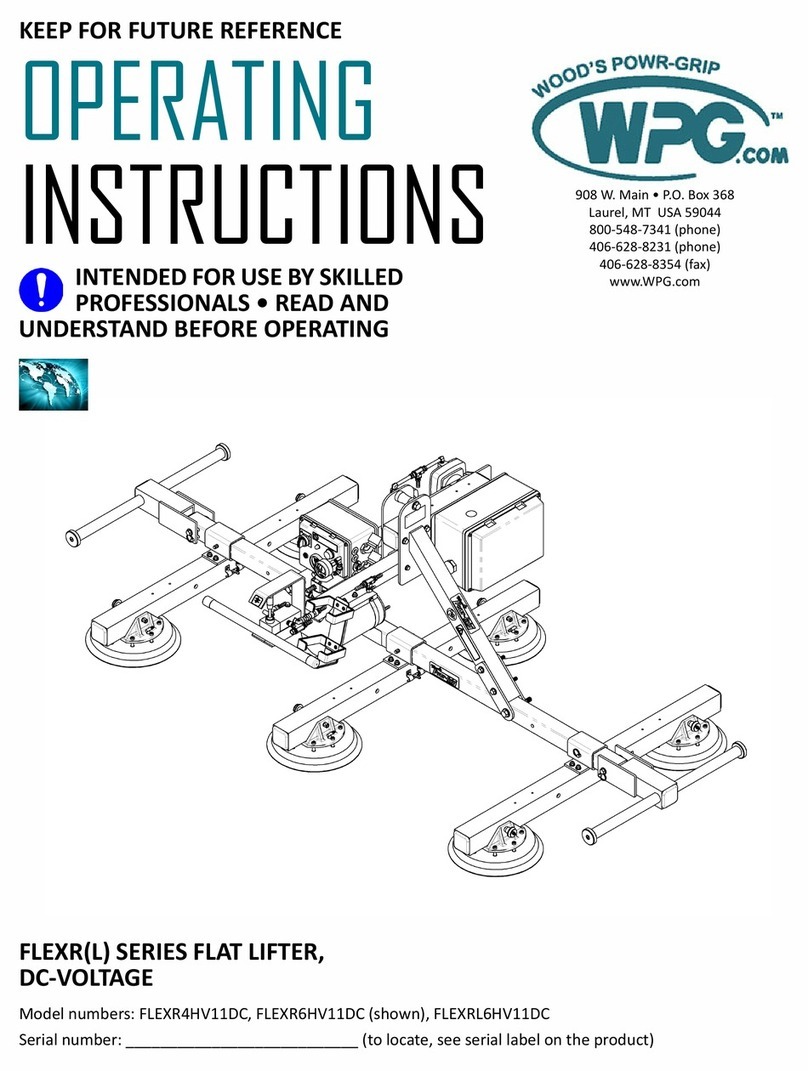

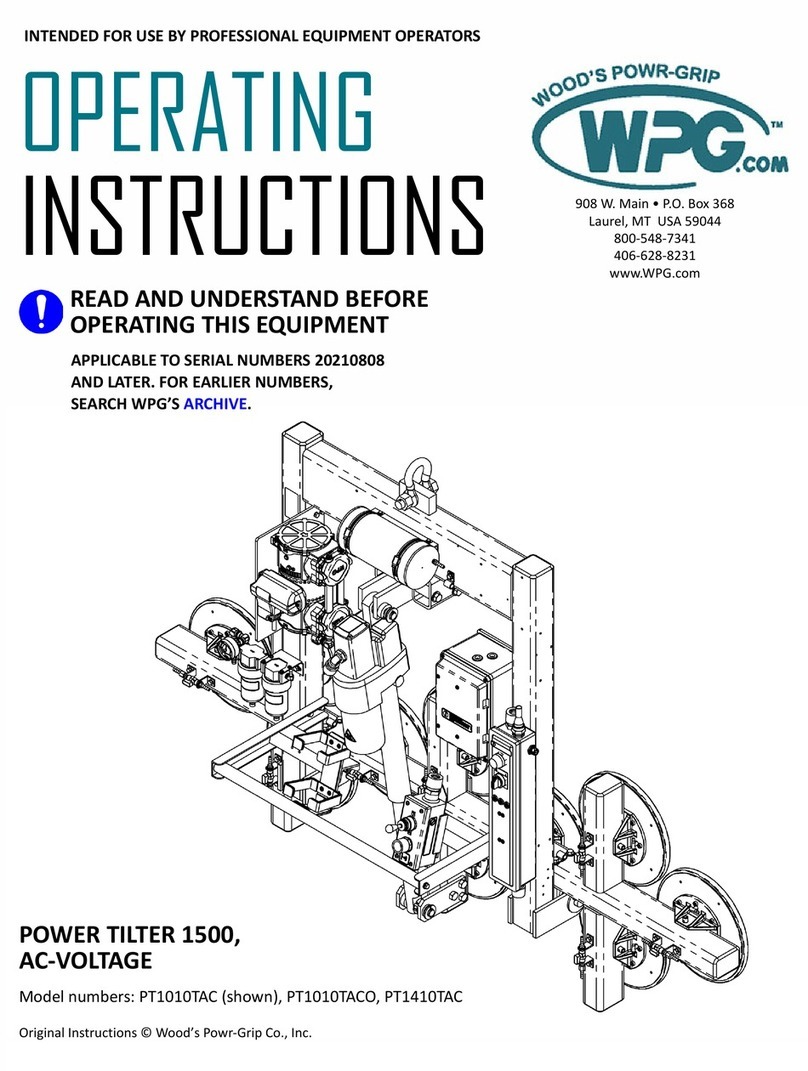

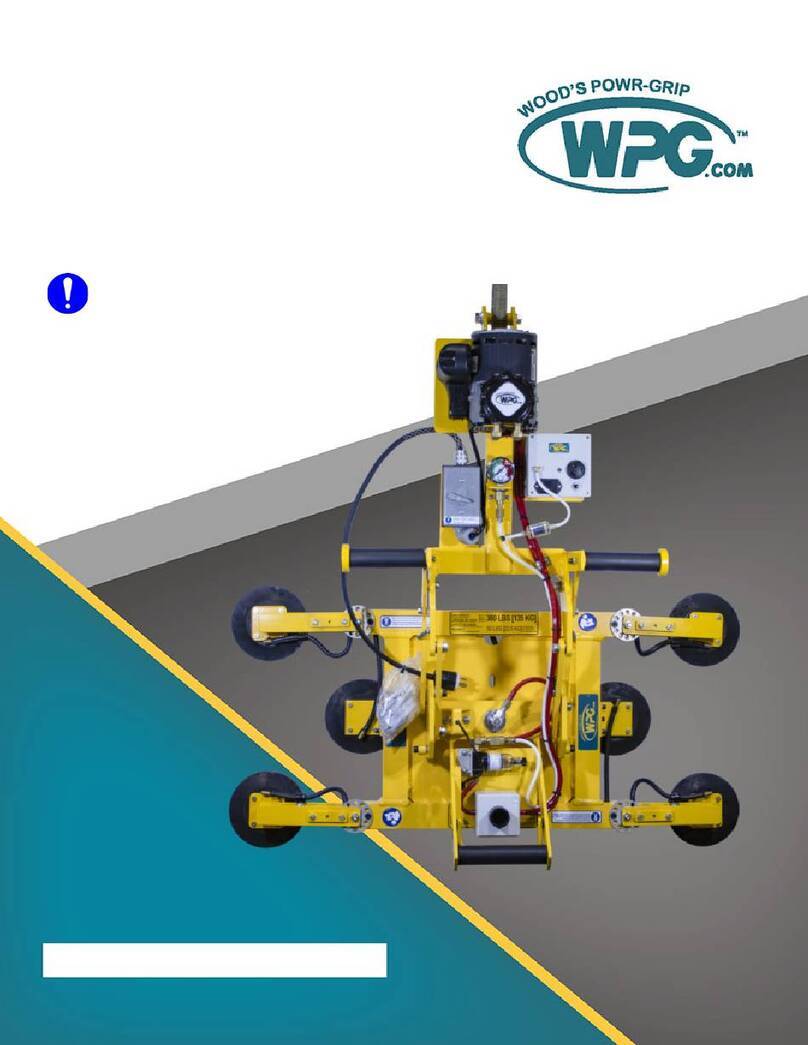

OPERATING FEATURES............................................................................6

ASSEMBLY..............................................................................................7

INTENDED USE .......................................................................................9

LOAD CHARACTERISTICS.................................................................................9

OPERATING ENVIRONMENT..........................................................................10

DISPOSAL OF THE LIFTER .............................................................................10

OPERATION..........................................................................................11

BEFORE USING THE LIFTER...........................................................................11

Taking Safety Precautions .................................................................................................11

Performing Inspections and Tests .....................................................................................11

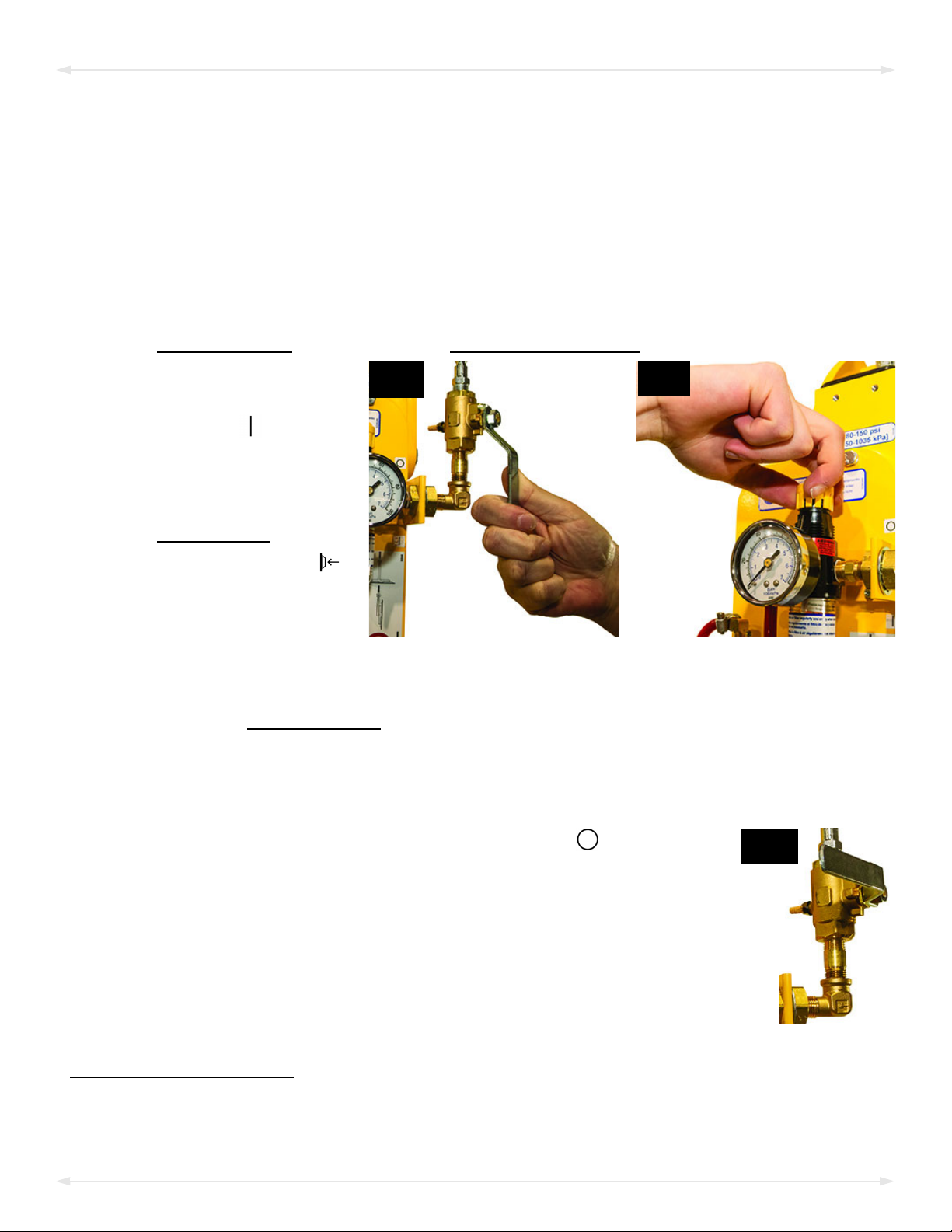

TOUSE THE OPTIONAL PAD SHUTOFFS ..........................................................12

TOADJUST PAD POSITIONS..........................................................................13

Positioning Pad Arms ........................................................................................................13

Positioning Pad Mounts ....................................................................................................14

TOADJUST THE CONTROL HANDLES ..............................................................14

TOATTACH THE PADS TO ALOAD ..................................................................15

Generating Airflow............................................................................................................15

Positioning the Lifter on the Load.....................................................................................15

Sealing the Pads on the Load............................................................................................16

Reading the Vacuum Gauge..............................................................................................16

TOLIFT AND MOVE THE LOAD......................................................................17

Interpreting the Vacuum Gauge .......................................................................................17

Watching the Vacuum Gauge............................................................................................17

Controlling the Lifter and Load .........................................................................................18

In Case of a Power Failure.................................................................................................18

TORELEASE THE PADS FROM THE LOAD .........................................................19

About Stand-By Mode.......................................................................................................19

AFTER USING THE LIFTER.............................................................................20

Storing the Lifter ...............................................................................................................20

Transporting the Lifter ......................................................................................................20

INSPECTIONS AND TESTS......................................................................21

TABLE OF CONTENTS