3 Unit Installation

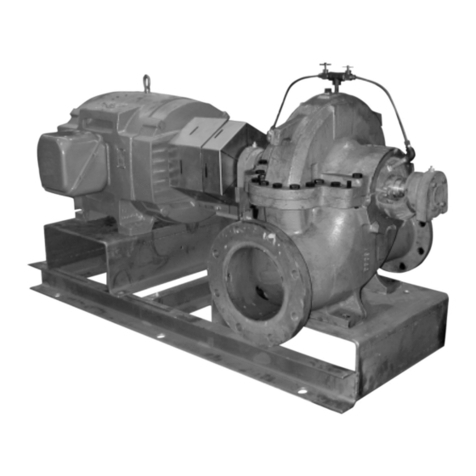

• Position the unit as shown.

• Install the unit according to the liquid flow of the system.

• The arrows on the pump body indicate the flow and the rotation direction.

• The standard rotation direction is clockwise (looking at the fan cover).

• Always install a backflow-prevention device on the suction side.

• Always install the pressure sensor on the delivery side, after the check valve.

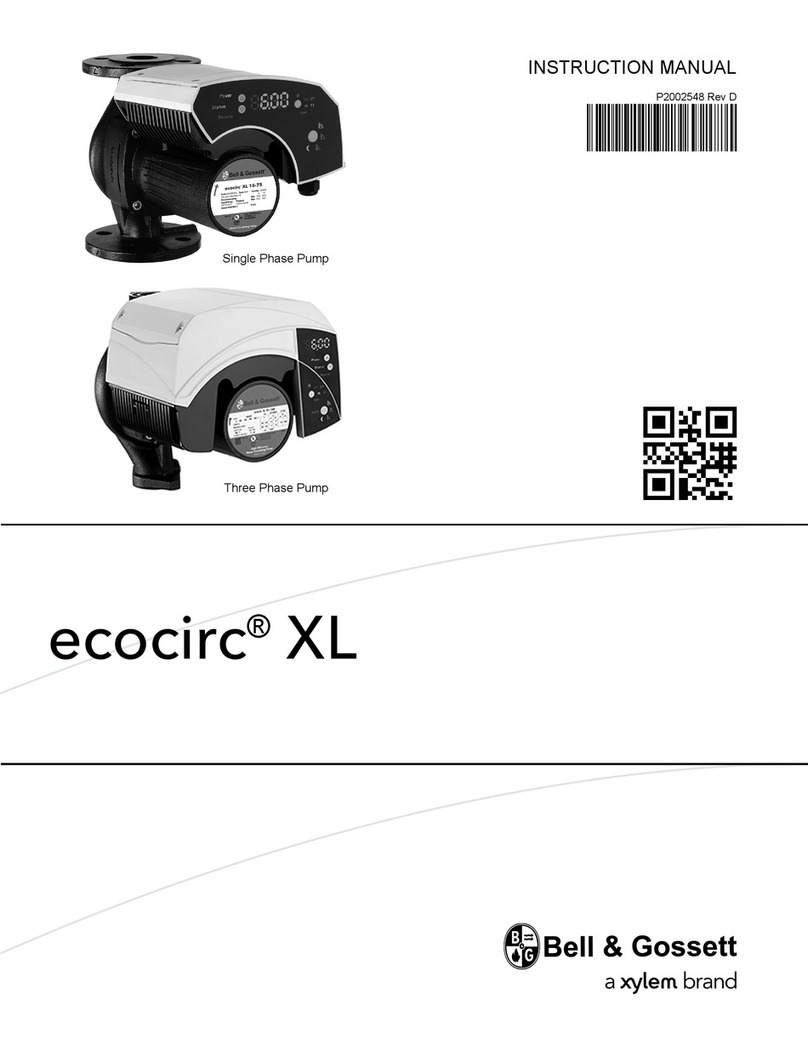

4 Check Rotation

1. Unlock power to the driver.

2. Make sure that everyone is clear, and then jog the driver long enough to determine that the direction of rotation corresponds

to the arrow on the pump. Pump rotation is clockwise when viewed from the back of the motor. An arrow is provided to show

rotational direction.

3. Lock out power to the driver.

5 Piping Requirements

Check that a section of straight pipe, with a length that is a minimum of five times

its diameter, is installed between the suction side of the pump and the first elbow,

or that a B&G Suction Diffuser is installed.

Check that you have a foot valve of equal or greater area than the pump suction

piping when you use in an open system with a suction lift.

Check that the suction and discharge pipes are supported independently by use of

pipe hangers near the pump.

Check that a B&G Triple Duty® valve is installed in the discharge line.

Check that there is a strong, rigid support for the suction and discharge lines. Check that the pipeline has isolation valves around the pump and has a drain valve

in the suction pipe.

For pumps with flanges, check that the bolt holes in the pump flanges match the

bolt holes in the pipe flanges.

Use PTFE tape sealer or a high quality thread sealant when you install the suction

and discharge connections to a threaded pump housing.

Check that the suction or discharge lines are not forced into position. On an open system, check that the end of the suction pipe is at least 3 ft. below the

surface of the water in the suction well.

Check that fittings for absorbing expansion are installed in the system when con‐

siderable temperature changes are expected.

Check that new flange gaskets are installed between the flanges of the pump body

suction and discharge pipes. Make sure that these gaskets are clean and grease-

free.

Xylem Product Cybersecurity

Xylem values system security and resilience. Defending against cybersecurity

threats is a shared responsibility. Xylem builds products that are secure by de‐

sign. Our customers have a responsibility to understand the risks inherent in their

processes and take steps to operate and maintain their solutions securely. For

details and updates on Xylem product cybersecurity visit xylem.com/security

For safety and correct product usage, read the manual before this product is used.

Xylem Inc.

8200 N. Austin Avenue, Morton Grove, IL 60053

Tel: (847) 966–3700, Fax: (847) 965–8379

www.xylem.com/bellgossett

Xylem and Bell & Gossett are registered trademarks of Xylem Inc. or

one of its subsidiaries. All other trademarks or registered trademarks

are property of their respective owners.

P2005926_Rev A_en-US_2022-12_QG_Series e-90E Smart Pump