PUMP TROUBLESHOOTING CHART

Failure to prime - motor operates, but no pump discharge

• Restricted intake or discharge line. Open all line valves,

check for “jammed” check valves, and clean clogged lines.

• Air leak in intake line.

• Punctured pump diaphragm.

• Defective pump check valves.

• Crack in pump housing.

• Debris in check valves.

• Missing or damaged o-ring of control valve chamber.

• Pinched/kinked hose.

• Damaged

Motor fails to turn on

• Pump or equipment not plugged in electrically.

• Loose wiring connection.

• Pressure switch failure.

•Defective motor or rectier.

• Frozen cam/bearing.

AVAILABLE MODELS

Visit www.ojet.com for a complete list models numbers.

PREVENTIVE MAINTENANCE TIPS

If pumping a liquid other than water, the pump should be

ushed with water (if applicable) after each use. Sealers acting

as a lubricant can cause cracked housings or stripped threads

due to over-tightening. Care should be used when applying

sealers; the tape may enter the pump, thus inhibiting valve ac-

tion and causing no prime or no shut-off conditions. Failures

due to foreign debris are not covered under warranty.

Before freezing conditions occur, the pump must be liquid free

or winterized with proper anti-freezing chemicals. If mount-

ing the pump in an outdoor environment, the pump should

be shielded from water, dust, sunlight, and washdown spray.

Do not assume chemical compatibility. If the uid is improper-

ly matched to the pump’s elastometers, the pump may fail to

prime, have low pressures, or the pressure switch may not shut

off. Contact your supplier for advice.

SERVICE KITS

Kits are readily available to repair standard Triplex High Pres-

sure Series pumps. To insure that the correct kits are received,

the model number and all name plate data must be included

with the order. Contact a FLOJET distributor to order the nec-

essary repair kits.

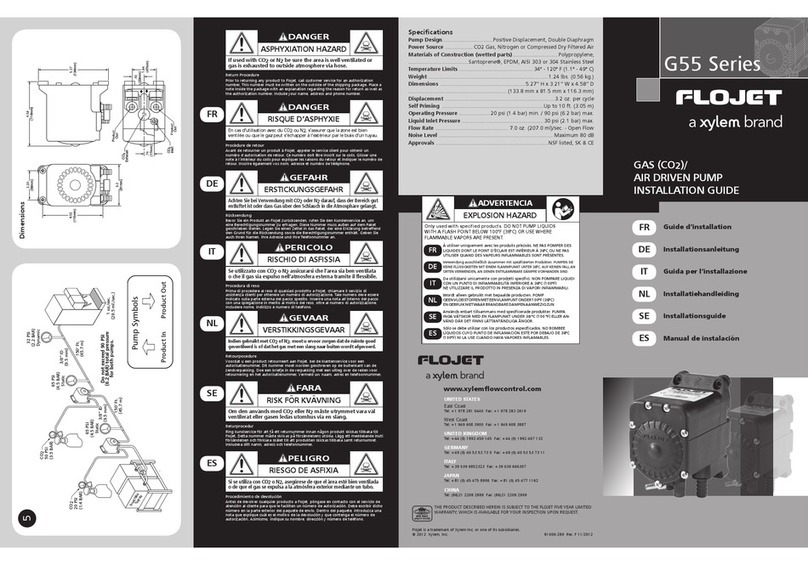

RETURN PROCEDURE

Prior to returning any product to FLOJET, call customer service

for an authorization number. This number must be written on

the outside of the shipping package. Place a note inside the

package with an explanation for return as well as the authoriza-

tion number. Include your name, address and phone number.

MSDS required.

PRODUCT WARRANTY

XYLEM LIMITED WARRANTY WARRANTS THIS PRODUCT TO BE FREE

OF DEFECTS AND WORKMANSHIP FOR A PERIOD OF 2 YEARS. THE

WARRANTY IS EXCLUSIVE AND IN LIEU OF ANY AND ALL OTHER EX-

PRESS OR IMPLIED WARRANTIES, GUARANTEES, CONDITIONS OR

TERMS OF WHATEVER NATURE RELATING TO THE GOODS PROVID-

ED HEREUNDER, INCLUDING WITHOUT LIMITATION ANY IMPLIED

WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A PARTIC-

ULAR PURPOSE, WHICH ARE HEREBY EXPRESSLY DISCLAIMED AND

EXCLUDED. EXCEPT AS OTHERWISE PROVIDED BY LAW, BUYER’S

EXCLUSIVE REMEDY AND SELLER’S AGGREGATE LIABILITY FOR

BREACH OF ANY OF THE FOREGOING WARRANTIES ARE LIMITED TO

REPAIRING OR REPLACING THE PRODUCT AND SHALL IN ALL CASES

BE LIMITED TO THE AMOUNT PAID BY THE BUYER HEREUNDER. IN

NO EVENT IS SELLER LIABLE FOR ANY OTHER FORM OF DAMAGES,

WHETHER DIRECT, INDIRECT, LIQUIDATED, INCIDENTAL, CONSE-

QUENTIAL, PUNITIVE, EXEMPLARY OR SPECIAL DAMAGES, INCLUD-

ING BUT NOT LIMITED TO LOSS OF PROFIT, LOSS OF ANTICIPATED

SAVINGS OR REVENUE, LOSS OF INCOME, LOSS OF BUSINESS, LOSS

OF PRODUCTION, LOSS OF OPPORTUNITY OR LOSS OF REPUTA-

TION. THIS WARRANTY IS ONLY A REPRESENTATION OF THE COM-

PLETE LIMITED WARRANTY. FOR A DETAILED EXPLANATION, PLEASE

VISIT US AT:

WWW.XYLEMFLOWCONTROL.COM/FLOJET-WARRANTY, CALL OUR

OFFICE NUMBER LISTED, OR WRITE A LETTER TO YOUR REGIONAL

OFFICE.

Pump fails to turn off after discharge valves are closed

• Depletion of available liquid supply.

• Punctured pump diaphragm.

• Discharge line leak.

• Defective pressure switch.

•Insufcient voltage to pump.

• Debris in check valves.

Low ow and pressure

•Defective check valves (most cases).

• Air leak at pump intake.

• Accumulation of debris inside pump and plumbing.

•Worn pump bearing (excessive noise).

• Punctured pump diaphragm.

•Defective rectier or motor.

•Insufcient voltage to pump.

Pulsating ow - pump cycling on and off

•Restricted pump delivery. Check discharge lines, ttings,

valves and spray nozzles for clogging or undersizing.

© 2015 Xylem Inc. All right reserved. Flojet is a trademark of Xylem Inc. or one of its subsidiaries.

81000-417 Rev. E 9/2015