Parameter

Value

Description

Reference

Comments

b5-03 3.0 sec. PI Integral Time Decrease integral time to make iQpump more responsive. Caution: can cause instability if

value is too low.

b5-12 2

(Fault)

PI Feedback Reference Missing

Detection Selection

Select what to do when the feedback device (transducer) fails or gets disconnected.

0: Disabled, continue running no message is displayed

1: Alarm, show warning on the keypad when the feedback device fails or is disconnected

2: Fault, stop pump system when the feedback fails or is disconnected

NOTE: Disable parameter b5-12

if no transducer is installed.

b5-14 2.0 sec. PI Feedback Loss Detection Time

Delay time before iQpump shows alarm or fault when feedback device has failed or is

disconnected. Example: 2.0 sec., iQpump displays alarm or fault 2 sec. after the device has

failed or is disconnected.

C1-01 20.0 sec. Acceleration Time 1 Time it takes to accelerate the pump motor from zero to maximum speed.

Adjusted depending on system

performance

C1-02 10.0 sec. Deceleration Time 1 Time it takes to decelerate the pump motor from maximum speed to zero.

L5-01 5 Number of Restart Attempts

Determines the number of times iQpump will perform an automatic restart on the faults listed

in the comments column.

iQpump System Protection Faults that can be setup to restart are Low Level Feedback,

High Level Feedback, Transducer Loss, Not Maintaining Set-point, Loss of Prime,

Pump Over Cycle. Refer to parameters P4-07 and P4-08. The number of restart attempts is

set by L5-01.

Overcurrent

Ground Fault

Output Phase Loss

Input Phase Loss

iQpump Overload

Motor Overload

Overtorque

DC Bus Fuse Blown

DC Bus Undervoltage

DC Bus Overvoltage

Overheat

L5-03 20 sec. Maximum Restart Time After Fault If the restart fails (or is not attempted due to a continuing fault condition) iQpump waits the

Maximum Restart Time After Fault, before attempting another restart.

P1-06 40.0 Hz Minimum Pump Frequency

Minimum speed (Hz) the pump motor has to operate at.

Example: Base pump motor speed is 3600 RPM, minimum speed is 2400 RPM. Set minimum

pump frequency to 40.0 Hz. (2400 ÷ 3600 x 60 Hz = 40 Hz)

P1-06 should be set to the level

where the pump can produce the

minimum pressure even at zero

flow.

P2-03 5 sec. Sleep Delay Time Time it takes before the pump system goes to sleep when the selected signal level (P2-01)

falls below the specified sleep level (P2-02)

Adjust according to system

requirements.

P4-05 30.0 Hz Thrust Bearing Frequency Sets the frequency reference used when the thrust bearing function is active. A value of 0

disables this function.

Primarily used for submersible

pumps. Program P4-05 = 0.0 Hz

to disable function when iQpump

is used with a centrifugal pump.

P4-11 0.2 Min Utility Start Delay When utility power is restored and P4-10 is enabled (1), iQpump waits the time specified in

P4-11 before auto operation becomes active.

Note: Only active when P4-10 is

enabled (1) and operation

(start/stop) is from the

digital operator.

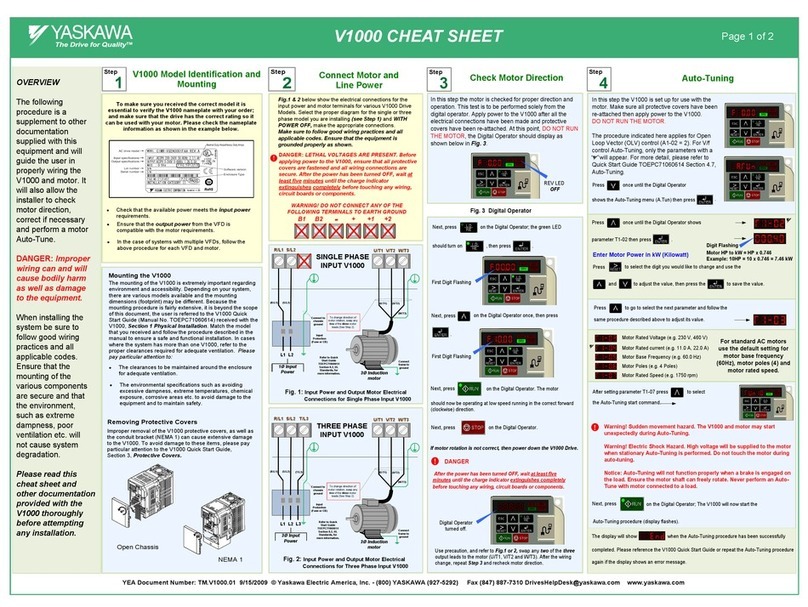

Step

5

iQpump Factory Defaults Overview (only adjust settings based on your application)

THRUST BEARING - SUBMERSIBLE MOTORS (e.g. Franklin)

When using a submersible motor in combination with iQpump, it is recommended to use the Thrust Bearing

function to prevent excess motor wear. To enable this function, enter the minimum motor frequency in parameter

P4-05. Example: Minimum motor speed 1800 RPM, 1800 RPM ÷ 3600 RPM x 60.0 Hz = 30.0 Hz

Output Frequency

Output Frequency

Thrust Bearing Frequency P4-05

(Example 30.0 Hz)

Time

Thrust Bearing Auto/Hand Operation

Turn Off Thrust Bearing Function

(Output Frequency Reached)

P4-04Accel.Time

Thrust Acceleration Time P4-04

(Example 1.0 sec.)

C1-01 Acceleration Time

5

AUTO OPERATION – POWER DOWN STORAGE

6

Allows iQpump to automatically start after power failure when operated from keypad / digital operator. This function

is recommended for use when operating the iQpump in remote / unmanned areas.

When the iQpump is powered down while running, an internal run

command will automatically be initiated upon power-up.

HAND MODE OPERATION

4

Hand Mode speed can be adjusted by pressing , use

to move the cursor and to adjust the hand speed reference.

Press to save new active hand speed reference.

Hand Speed from the Keypad/Digital Operator (Default)

Set parameter P5-01 ‘Hand Mode Ref.’ to ‘0’ to adjust the hand mode

reference from an external 0 – 10V signal connected to terminal A1 and AC.

Hand Speed from Analog Input (0 – 10V)

S3 S5 S6 S7 FM AC AM IGS2 S4S1 S+ S-

SP A2 +V AC ACSC A1SN R+ R-

+-

0 – 10V

Press the HAND KEY on the digital operator to run the system in Hand Mode.

‘0’ Blinking

HAND KEY

Note: Hand Key can be disabled with parameter P5-04

Note: Thrust Bearing Function is Enabled by Default

Page 3 of 4

iQpump 7 AC Drive (Software 0034)

Simplex Quick Start Procedure