IM05C01F12-01E 3rd Edition Feb. 29, 2016-00

2

Measured Value (PV) Input

●Input: 1 point

●Input type: Universal; can be selected by software

●Input accuracy (at 23 ±2°C ambient temperature)

●Thermocouple:±2°C±1digit

However,

• ±4°C for thermocouple input –270 to –100°C

• ±3°C for thermocouple input –100 to 0°C

• ±5°C for types R and S (±9°C for 0 to 500°C)

• ±9°C for type B (accuracy is not guaranteed

for 0 to 400°C)

●RTD:±1°C±1digit

●Voltage(mV,V):±0.3%±1digit

●Sampling period for measured value input: 500ms

●

Burn-out detection: Functions for thermocouple or RTD input

(burn-out upscale only; cannot be switched off)

●Inputresistance:1MΩorgreaterforthermocouple

orDCmVinput.Approx.1MΩforDCVinput

●Maximum allowable signal source resistance :

250ΩforthermocoupleorDCmVinput

2kΩforDCVinput

●

Maximum allowable wiring resistance for RTD input:

10Ω/wire(Theresistancevaluesofthreewires

must be the same.)

●

Allowable input voltage:

±10V DC for thermocouple or DC mV input

±20V DC for DC V input

●

Noise rejection ratio:

Normal mode noise: Min. 40dB

(50/60Hz)

Common mode noise: Min. 120dB

(Min. 90dB for DC V input)

●Error of reference junction compensation:

±1.5°C (at 15-35°C), ±2.0°C (at 0-50°C)

The reference junction compensation cannot be

switched off.

●Applicable standards:

Thermocouple and resistance temperature

detector (RTD)

JIS/IEC/DIN (ITS90)

Contact Inputs

The contact inputs are provided only when the /EX

optionisspecied.

●Functions: (1) HOLD/Cancel HOLD switching

(2) RUN/RESET switching

●Input: 2 points (with the shared common terminal)

●Input type: Non-voltage contact or transistor

contact input

●Contact capacity: At least 12V/10mA

●On/offjudgment:Onstatefor1kΩorless;offstate

for20kΩorgreater

Control Output

●Output: 1 point

●Output type: Choose one from (1) to (3) below:

(1) Relay contact output

Contact capacity: 3A at 240V AC or 3A at 30V DC

(with resistance load)

Note: The control output relay cannot be replaced

by users.

(2) Voltage pulse output

On

voltage: 12-18V DC

Off

voltage: 0.1V DC or less

loadresistance:600Ωorgreater

short-circuit current: approx. 30mA

(3) Current output

Output signal: 4 to 20mA

Maximumloadresistance:600Ω

Outputaccuracy:±0.3%ofspan

(at 23±2°C ambient temperature)

Event Functions

PV Event Functions

●PV event types: 10 types

●PV high limit, PV low limit, Deviation high limit,

Deviation low limit, De-energized on deviation high

limit, De-energized on deviation low limit, Deviation

high and low limits, Deviation within high and low

limits, De-energized on PV high limit, De-energized

on PV low limit

Time Event Functions

The time event function begins countdown when

a program operation starts, and after the elapse

of a preset time, outputs an on-time event signal

(contact output: ON) or off-time event signal

(contact output: OFF).

●PV and Time event outputs: 2 relay contacts

Relay contact capacity: 1A at 240V AC or

1A at 30V DC

(with resistance load)

(COM terminal is common)

Note: The PV and time event output relays cannot

be replaced by users.

Retransmission Output

±2%ofprogramtime

Retransmission Output

The retransmission output is provided only when the

/REToptionisspecied.

●Output signal: Measured value in 4-20mA DC, can

be scaled.

●Maximumloadresistance:600Ω

●Outputaccuracy:±0.3%ofspan

(at 23±2°C ambient temperature)

Communication Function

The communication function is provided only when

the/RSoptionisspecied.(Fordetails,readthe

user's manual of the communications functions IM

05C01E12-10E.)

Communication Protocol

●Personal computer link: Used for communication

with a personal computer, or UT link module of

the FA-M3 controller (from Yokogawa Electric

Corporation).

●Ladder communication: Used for communication

with a ladder communication module of the FA-

M3, or a programmable controller (PLC) of other

manufacturers.

●MODBUS communication: Used for communication

with equipment featuring the MODBUS protocol.

Communication Interface

●Applicable standards: Complies with EIA RS-485

●

Number of controllers that can be connected: Up to 31

●Maximum communication distance: 1,200m

●Communication method: Two-wire half-duplex,

start-stop synchronization, non-procedural

●Baud rate: 2400, 4800, or 9600 bps

Safety and EMC Standards

WARNING

This instrument is classied into the

Measurement Category No.1 in the

following table.

Do not use for the measurements in

locations where the categories are

No.2, No.3, and No.4.

Internal Wiring

Outlet

IV III

O(I)

TII

●

Safety: Compliant with IEC/EN 61010-1 (CE), IEC/

EN 61010-2-201 (CE), IEC/EN 61010-2-030 (CE),

approved by CAN/CSA C22.2 No. 61010-1 (CSA),

approved by UL 61010-1.

Installation category: II

Pollution degree: 2

Measurement category: I (CAT I) (UL, CSA)

O (Other) (CE)

Rated measurement input voltage: Max. 10 V DC

Rated transient overvoltage: 1500 V (*)

* This is a reference safety standard value for

measurement category I of CSA/UL 61010-1,

and for measurement category O of IEC/EN

61010-2-030. This value is not necessarily a

guarantee of instrument performance.

●EMC standards: Complies with EN 61326.

The instrument continues to operate at a measuring

accuracyofwithin±20%oftherangeduringtests.

●KC marking: Electromagnetic wave interference

prevention standard, electromagnetic wave

protection standard compliance

No.

IEC/EN/CSA/

UL 61010-1

EN 61010-

2-030 Description

No.1 Measurement

Category I O (Other)

For measurements

performed on circuits not

directly connected to MAINS.

No.2 Measurement

Category II

Measurement

Category II

For measurements

performed on circuits

directly connected to the

low voltage installation.

No.3 Measurement

Category III

Measurement

Category III

For measurements

performed in the

building installation.

No.4 Measurement

Category IV

Measurement

Category IV

For measurements

performed at the source of

the low-voltage installation.

Power Supply and Isolation

CUATION

Caution to comply with EMC Standards:

When operating this instrument by external

power supply, use an independent power

unit conforming to CE marking.

Power Supply

Power

supply

Voltage

Ratedat100-240VAC(±10%)

AC/DC 24V, 20 to 29V of

allowable range when

"/V24"isspecied.

Frequency 50 or 60Hz

Maximum power

consumption

8VA max. (4W max.)

3W max. when

"/V24"isspecied.

Memory Non-volatile memory

Withstanding

voltage

Between primary

terminals and

secondary terminals

(See Notes 1 and 3.)

CE: 3000 V AC for 1 minute

(Between relay terminals

and secondary terminals

1500 V AC for 1 minute)

UL/CSA: 1500 V AC for 1

minute (Note 2)

Insulation

resistance

Between primary

terminals and

secondary terminals

(See Notes 1 and 3.)

20MΩormoreat

500V DC

Note 1:

The primary terminals are the power supply

terminals and event output terminals.

The secondary terminals are the analog input

and output terminals, the voltage pulse output

terminals, and the contact input terminals.

Note 2:

Thewithstandingvoltageisspeciedas2300

V AC per minute to provide a margin of safety.

Note 3:

AC/DC 24V terminals are secondary terminals.

Isolation

The bold lines below indicate reinforced isolation,

and the broken line indicates functional isolation.

In case of CE conformity, alternate long and short

dash line indicates basic insulation.

•Measured value input

terminals

•2 input terminals

for /EX

•Internal circuit

•

Control output

terminals

(relay contacts)

•

Event output

terminals

(2 relay contacts)

•

Control output terminals:

4-20 mA/Voltage pulse

•

Retransmission output terminals:

4-20 mA

•RS-485 terminals

for /RS

•Power supply

terminals

(100-240V AC)

•Power supply

terminals AC/DC 24V

(When “/V24” is specified)

Reinforced insulation

Functional insulation

In case of CE conformity,

alternate long and short dash

line indicates basic insulation.

Note:

Neither the measured value input terminals, nor 2

input terminals for the /EX option are isolated from

the internal circuit.

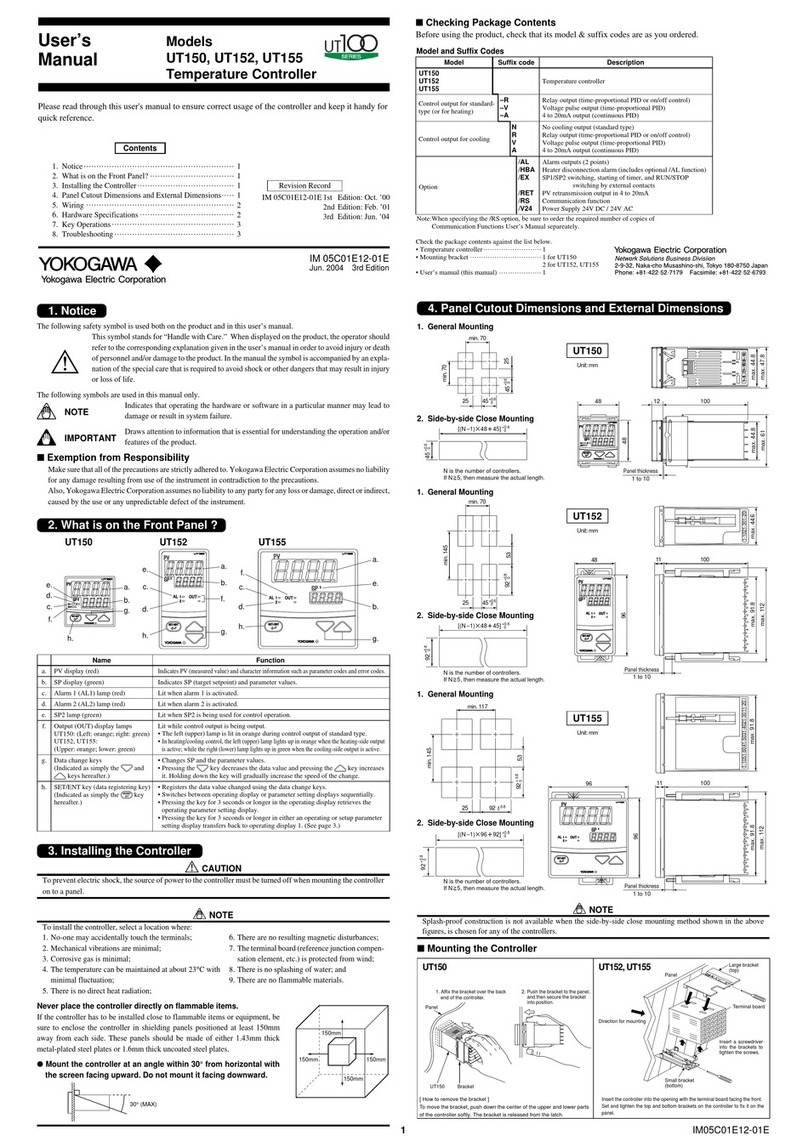

Construction, Mounting, and Wiring

●Construction: Dust-proof and drip-proof front panel

conforming to IP65.

For side-by-side close installation the controller

loses its dust-proof and drip-proof protection.

●Casing: ABS resin and polycarbonate

●Case color: Black

●Weight: approx. 200g

●Mounting: Flush panel mounting

●Wiring: Screw terminals

Environmental Conditions

Normal Operating Conditions

●Warm-up time: At least 30 minutes

●Ambient temperature:0-50°C (0-40°C when

mounted side-by-side)

●Rate of change of temperature: 10°C/h or less

●

Ambienthumidity:20-90%RH(nocondensationallowed)

●Magneticeld:400A/morless

●Continuous vibrations of 5 to 14Hz: Amplitude of

1.2mm or less

●Continuous vibrations of 14 to 150Hz: 4.9m/s2

(0.5G) or less

●Short-period vibrations: 14.7m/s2(1.5G) for 15

seconds or less

●Shock: 98m/s2(10G) for 11 milliseconds or less

●Mounting angle: Upward incline of up to 30

degrees; downward incline is not allowed.

●Altitude: 2000m or less above sea level

Maximum Effects from Operating Conditions

(1) Temperature effects

●Thermocouple,DCmVandDCVinput:±2μV/°C

or±0.02%ofF.S./°C,whicheverislarger

●Resistance temperature detector: ±0.05°C/°C

●Analogoutput:±0.05%ofF.S./°C

(2)Effectfromuctuationofpowersupplyvoltage

(within rated voltage range)

●Analoginput:±0.2μV/Vor±0.002%ofF.S./V,

whichever is larger

●Analogoutput:±0.05%ofF.S./V

Transportation and Storage Conditions

●Temperature: –25 to 70°C

●Humidity:5to95%RH(nocondensationallowed)

●Shock: Package drop height 90cm (when packed

in the dedicated package)

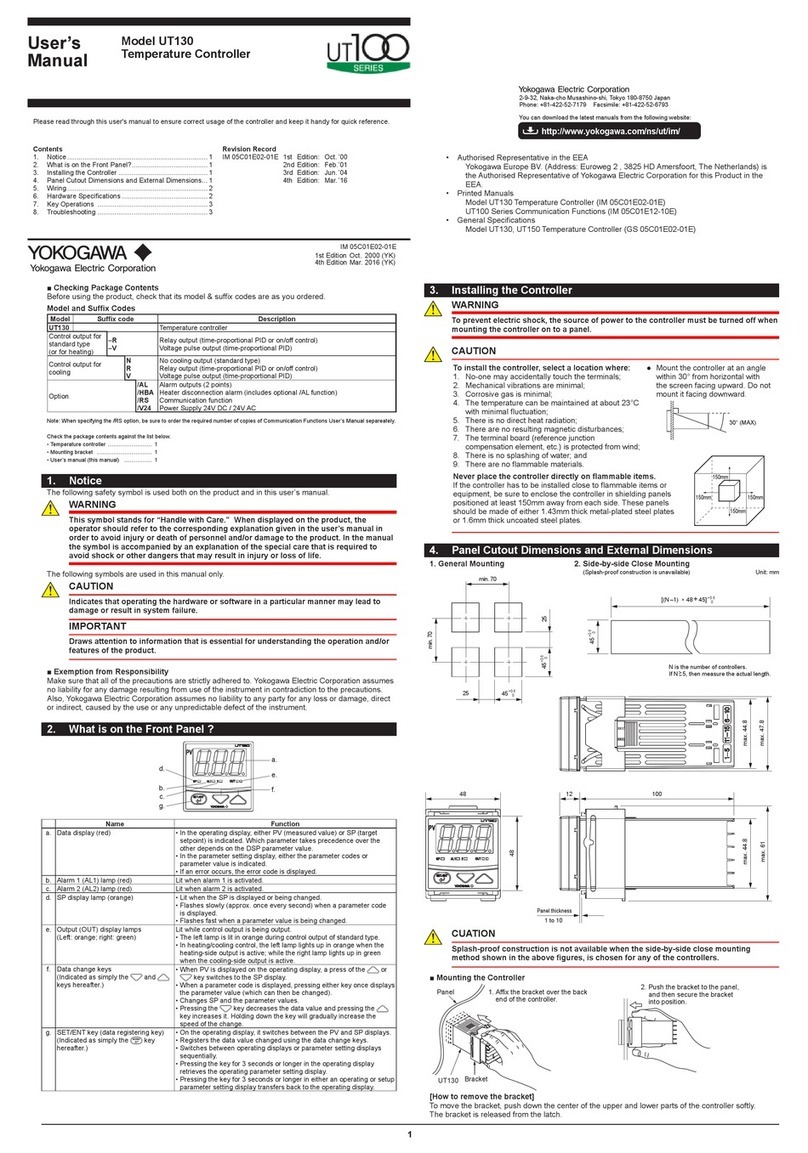

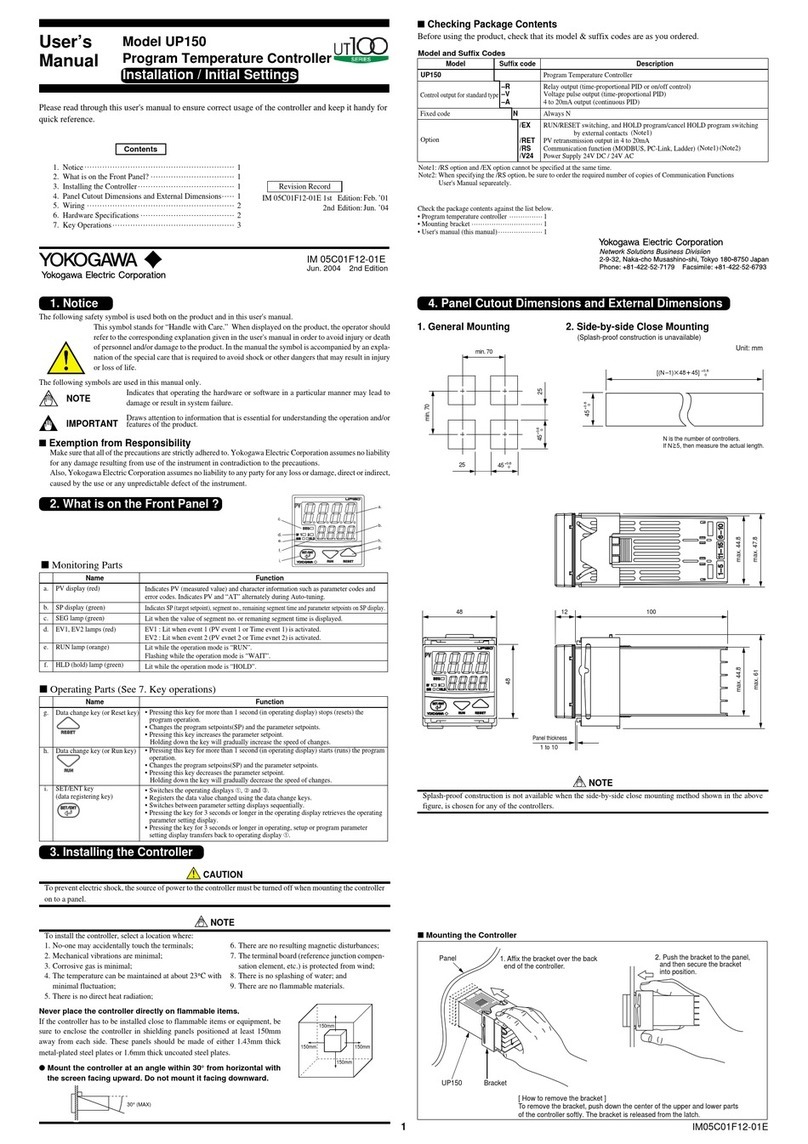

5. Wiring

WARNING

1) Before you start wiring, turn off the power source and use a tester to check that the controller and

cables are not receiving any power in order to prevent electric shock.

2) For safety, be sure to install a circuit breaker switch (of 5A and 100V AC or 220V AC, and that

conforms to IEC60947) near the instrument so as to be operated easily, and clearly indicate that

the device is used to de-energize the instrument.

3) Wiring should be carried out by personnel with appropriate electrical knowledge and experience.

4) For the wiring cable, the temperature rating is 60 °C or more.

CAUTION

1) Use a single-phase power source. If the source has a lot of noise, use an isolation transformer for

the primary side and a line lter (we recommend TDK’s ZAC2205-00U product) for the secondary

side. When this noise-prevention measure is taken, keep the primary and secondary power cables

well apart. Since the controller has no fuse, be sure to install a circuit breaker switch (of 5A and

100V AC or 220V AC, and that conforms to IEC standards) and clearly indicate that the device is

used to de-energize the controller.

2) For thermocouple input, use shielded compensating lead wires. For RTD input, use shielded wires

which have low resistance and no resistance difference between the 3 wires. See the table given

later for the specications of the cables and terminals and the recommended products.

3) The control output relay cannot be replaced even though it has a limited service life (100,000 relay

contacts for the resistance load). Thus, an auxiliary relay should be used so that the load can be

turned on and off.

4) When using an inductive load (L) such as an auxiliary relay and solenoid valve, be sure to insert

a CR lter (for AC) or diode (for DC) in parallel as a spark-rejecting surge suppressor to prevent

malfunctions or damage to the relay.

5) When there is the possibility of being struck by external lightening surge, use the arrester to

protect the instrument.

IMPORTANT

Always x a terminal cover bracket to the UP150 controller before wiring if an optional anti-electric-

shock terminal cover (part number: L4000FB) is used.

●Cable Specifications and Recommended Products

Power supply and relay contact output 600V vinyl insulated wire/cable, JIS C3307, 0.9 to 2.0mm2

Thermocouple input Shielded compensating lead wire, JIS C1610

RTD input Shielded wire (3-wire), UL2482 (Hitachi cable)

Other signals Shielded wire

●Recommended Terminals

Use M3.5 screw-compatible crimp-on terminals with an insulating sleeve, as shown below.

7mm or less

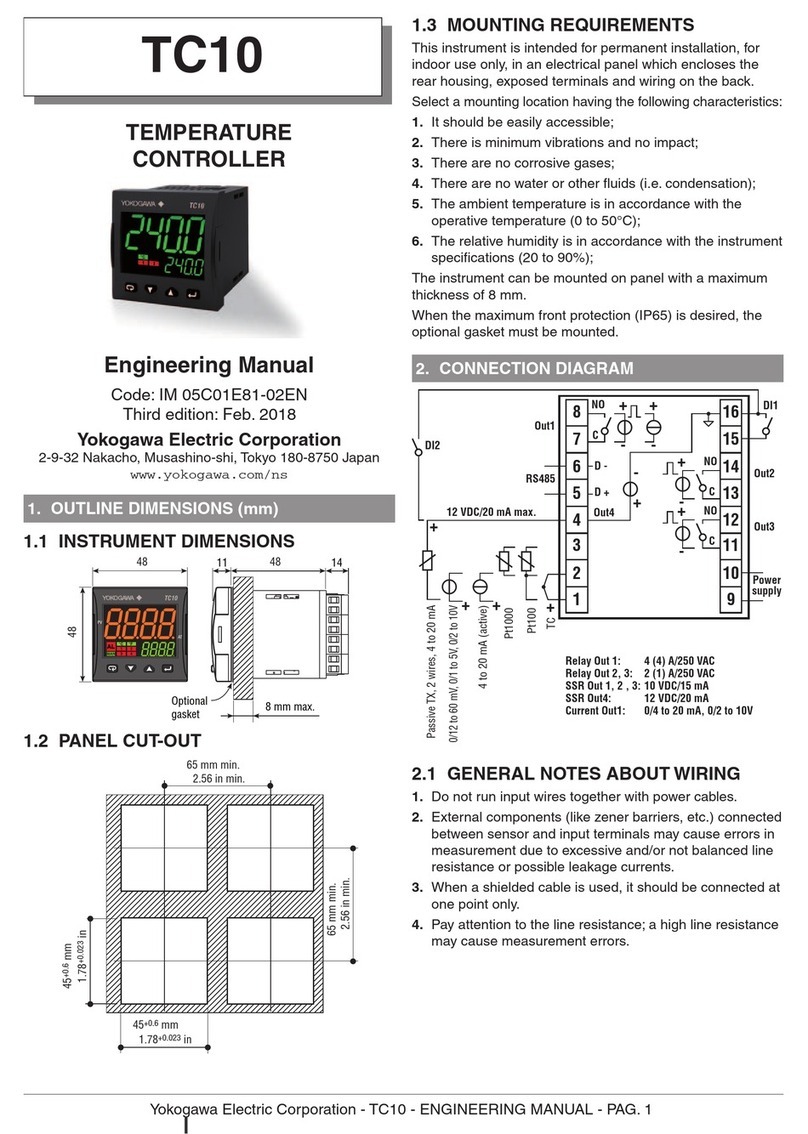

6. Hardware Specications

CAUTION

Do not use unassigned terminals as relay terminals.

CAUTION

The and stand for the polarity for DC 24V

power supply.

WARNING

To prevent damage to the controller, never provide

100-240V AC power supply for power supply AC/DC

24V model (when “/V24” is specied).

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

EV2

EV1

COM

PV or Time Event Outputs

11

12

13

External Contact Inputs

3

4

5

RUN

HOLD HOLD program when DI=ON.

Cancel HOLD program when DI=OFF.

Starts program (RUN) when DI=ON.

Resets program (RESET) when DI=OFF.

COM

When “/EX” is specified.

Can be used when DIS parameter is ON.

4 to 20 mA Output

Voltage Pulse Output

Control Output

Specify one for the output signal type.

14

15

+

–

14

15

+

–

Relay Contact Output

14

15

NO

COM

RS-485

3

4

5

RSB(+)

RSA(–)

SG

When “/RS” is specified.

Standard Type (Models UP150-N)

Power Supply

9L

N

10

100-240V AC

9

10

AC/DC 24V

+

–

TC Input RTD Input

7

8

6

7

8

+

–

B

b

A

Universal input-selectable

input type

DC mV or V Input

7

8

+

–

Measured Value (PV) Input

When “/RET”

is specified.

PV Retransmission Output

+

–

1

2

4 to 20 mA DC

(model UP150-RN) (model UP150-AN)

(model UP150-VN)

when /V24 option is specifed.

7

8

Note: Connecting a 250 Ωresistor to the terminals is

optional.

Model: X010-250-2 (resistor with M3.5 crimp-on terminal

lugs)

*

When receiving 4-20 mA DC current signals,

set the PV input type to 1-5 V DC (setpoint “22”).

Receiving 4-20 mA DC Current

Signals with the Controller

250

Ω

4-20mA

-

+

If the power is turned on, when the RUN/RESET external

contact input is ON, the controller is in runnig state. But

Hold/Cancel hold external contact input is ON, the controller

is in cancelling state.

CAUTION

Safety Precaution in IEC61010-1

Since the insulation provided to between relay

output terminal and secondary terminal is

Reinforced insulation, the connected circuit

should use a safety voltage circuit to comply with

IEC61010-1. (Refer to the drawing below.)

This product

Basic

Secondary-

side

A safety

voltage circuit