AFMNA0AA – EPS-BLI HYG – User Manual Page – 3/75

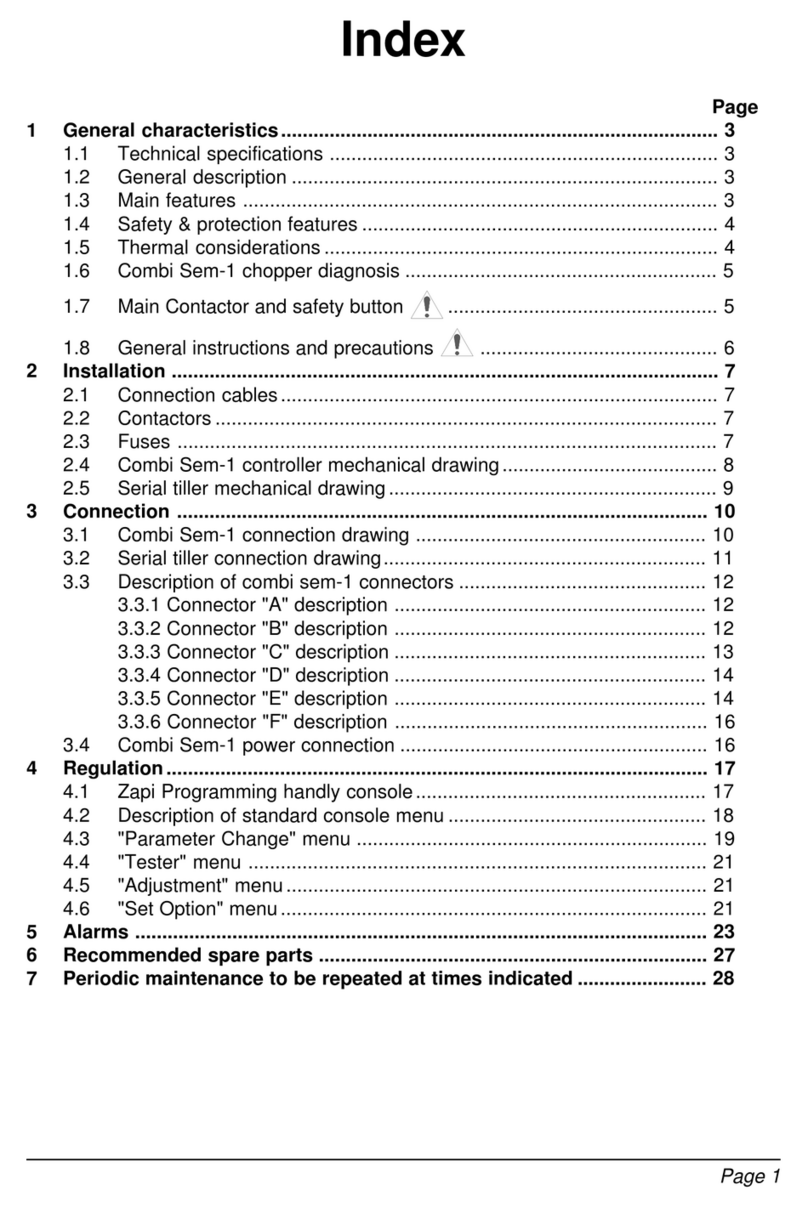

Contents

1INTRODUCTION...................................................................................................................5

1.1About this document................................................................................................... 5

1.1.1Manual Acronyms.........................................................................................5

1.2About the controller .................................................................................................... 6

1.2.1Safety ...........................................................................................................6

1.2.2OEM’s responsibility ..................................................................................... 6

1.2.3Technical support ......................................................................................... 6

2SPECIFICATIONS ................................................................................................................7

2.1General features......................................................................................................... 7

2.2Technical specifications .............................................................................................8

2.3Electrical specifications .............................................................................................. 8

2.4Motor specifications.................................................................................................... 8

3DRAWINGS...........................................................................................................................9

4BLOCK DIAGRAM..............................................................................................................10

4.1Position control......................................................................................................... 10

4.2Coordination between SCM and other modules in the truck .................................... 11

4.2.1Bringing TCM to a safe state ...................................................................... 11

4.2.2SCM has its own contactor.........................................................................12

4.2.3SCM directly on the DC Power rail ............................................................. 12

4.2.4A single MC, driven by the VCM, supplies power rail to all the modules.... 13

4.2.5A single MC, driven by the SCM, supplies power rail to all the modules.... 13

5SYSTEM COMPONENTS...................................................................................................14

5.1Steering motor and gear box.................................................................................... 14

5.2E-steering motor controller ....................................................................................... 14

5.3Feedback sensors ....................................................................................................14

5.3.1Feedback position sensor........................................................................... 14

5.3.2Straight ahead toggle switch ...................................................................... 15

5.4Sensor in the steering command..............................................................................15

5.4.1PWMs type sensor ..................................................................................... 15

5.4.2Force feedback........................................................................................... 16

6CONNECTION DRAWING..................................................................................................17

6.1Ampseal connector................................................................................................... 18

7INSTALLATION PROCEDURE ..........................................................................................19

7.1Prototype installation procedure...............................................................................19

8SETTING THE E-STEERING MOTOR CONTROLLER .....................................................20

8.1Prototype set-up .......................................................................................................20

8.2Quick set-up .............................................................................................................20

8.3ZERO SP POT self-acquisition.................................................................................21

8.4SET STEER 0-POS calibration ................................................................................ 21

9PROGRAMMING & ADJUSTMENTS.................................................................................22

9.1Zapi hand set............................................................................................................ 22

9.2Description of the parameter lists............................................................................. 22

9.2.1SET OPTIONS list ...................................................................................... 24

9.2.2ADJUSTMENTS list.................................................................................... 27

9.2.3SET MODEL list ......................................................................................... 30

9.2.4PARAMETER CHANGE list ....................................................................... 32

9.2.5HARDWARE SETTINGS list ......................................................................38