Page 1

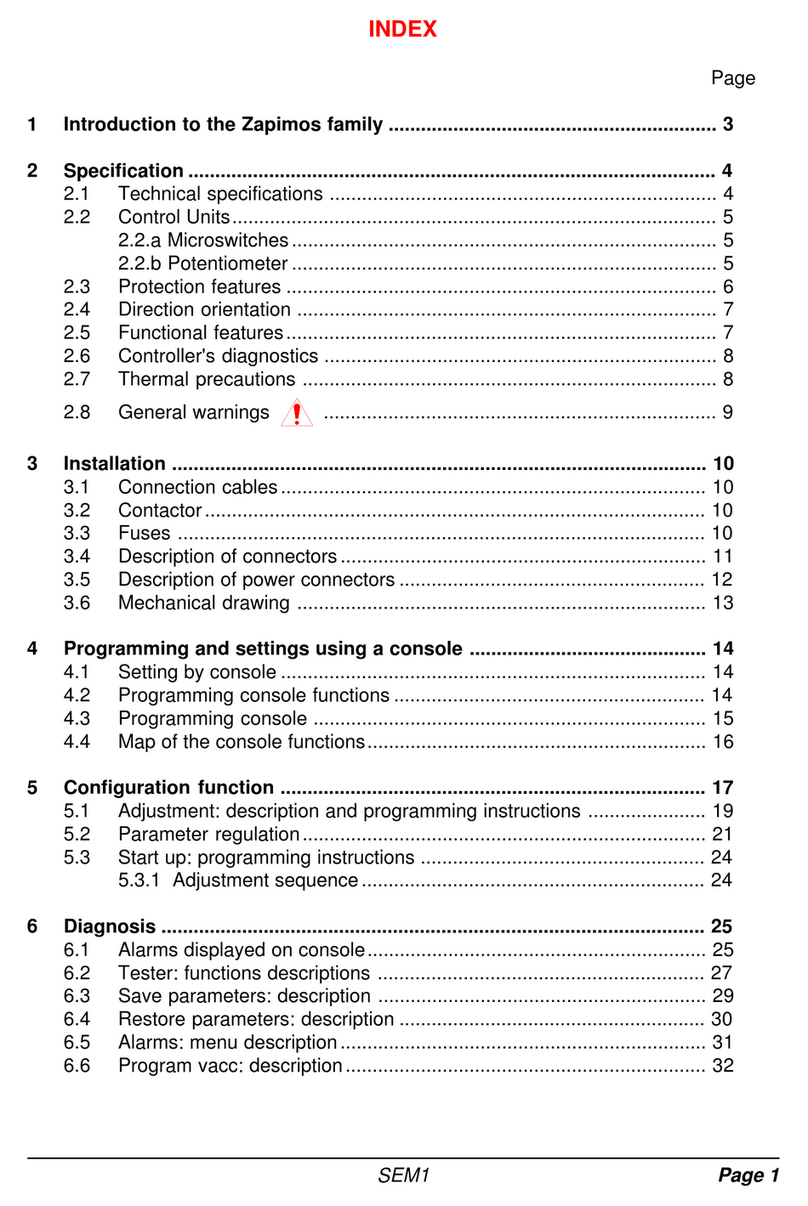

INDEX Page

LEGEND 3

COLOUR CODES (Single Colours) ...................................................................... 3

1 Introduction to the ZAPI-MOS family .......................................................... 4

2 General characteristics................................................................................. 5

2.1 Technical Specification.......................................................................... 5

2.2 Control Units.......................................................................................... 5

2.2.a Microswitches............................................................................... 5

2.2.b Potentiometer............................................................................... 6

2.3 Safety & Protection Features ................................................................ 7

2.4 Direction Orientation ............................................................................. 7

2.5 Operational Features ............................................................................ 8

2.6 SEM-Zero chopper diagnosis................................................................ 9

2.7 Thermal Considerations ........................................................................ 9

2.8 General Instructions and Precautions ................................................. 10

3 Installation ................................................................................................... 11

3.1 Connection Cables.............................................................................. 11

3.2 Contactors........................................................................................... 11

3.3 Fuses .................................................................................................. 11

3.4 Description of SEM-Zero Connectors.................................................. 12

3.5 Description of Power Connections ...................................................... 13

3.6 Mechanical Drawing & Dimensions..................................................... 14

4 Programming & Adjustments using Digital Console............................... 15

4.1 Adjustments via Console..................................................................... 15

4.2 Description of Console & Connection.................................................. 15

4.3 Description of Standard Console Menu............................................... 16

5 SEM-Zero: cabling and configuration ....................................................... 17

5.1 Power diagram .................................................................................... 17

5.2 Connections ........................................................................................ 18

5.3 Description of Programmable Functions (Options). ............................ 19

5.4 Description of Parameters that may be Programmed ......................... 21

5.5 Table of Adjustments........................................................................... 23

5.4 SEM-Zero Traction Standard Wiring Diagrams................................... 25

5.5 Sequence for SEM-Zero Traction Settings.......................................... 26

6SEM-Zero Diagnostics ................................................................................ 27

6.1 Analysis of Alarms displayed on the Console ..................................... 28

6.2 Tester Description of the Functions .................................................... 31

6.3 Description of the Console SAVE Function......................................... 33

6.4 Description of Console RESTORE Function. ...................................... 34

6.5 Description of Alarms Menu. ............................................................... 35

6.6 Description of Console PROGRAM VACC function. ........................... 36

7 Recommended Spare parts for SEM-Zero .................................................... 37

8 Periodic Maintenance to be repeated at times indicated ............................ 38