Page 1SEM1

INDEX

Page

1 Introduction to the Zapimos family ............................................................. 3

2 Specification .................................................................................................. 4

2.1 Technical specifications ........................................................................ 4

2.2 Control Units.......................................................................................... 5

2.2.a Microswitches............................................................................... 5

2.2.b Potentiometer............................................................................... 5

2.3 Protection features ................................................................................ 6

2.4 Direction orientation .............................................................................. 7

2.5 Functional features................................................................................ 7

2.6 Controller's diagnostics ......................................................................... 8

2.7 Thermal precautions ............................................................................. 8

2.8 General warnings ......................................................................... 9

3 Installation ................................................................................................... 10

3.1 Connection cables............................................................................... 10

3.2 Contactor............................................................................................. 10

3.3 Fuses .................................................................................................. 10

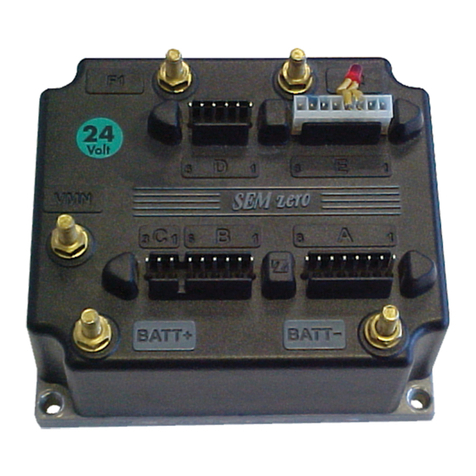

3.4 Description of connectors.................................................................... 11

3.5 Description of power connectors......................................................... 12

3.6 Mechanical drawing ............................................................................ 13

4 Programming and settings using a console ............................................ 14

4.1 Setting by console............................................................................... 14

4.2 Programming console functions.......................................................... 14

4.3 Programming console ......................................................................... 15

4.4 Map of the console functions............................................................... 16

5 Configuration function ............................................................................... 17

5.1 Adjustment: description and programming instructions ...................... 19

5.2 Parameter regulation........................................................................... 21

5.3 Start up: programming instructions ..................................................... 24

5.3.1 Adjustment sequence................................................................ 24

6 Diagnosis ..................................................................................................... 25

6.1 Alarms displayed on console............................................................... 25

6.2 Tester: functions descriptions ............................................................. 27

6.3 Save parameters: description ............................................................. 29

6.4 Restore parameters: description ......................................................... 30

6.5 Alarms: menu description.................................................................... 31

6.6 Program vacc: description................................................................... 32