ADPZP0CC - MHYRIO FLASH CONTROLLER - User Manual Page - 3/36

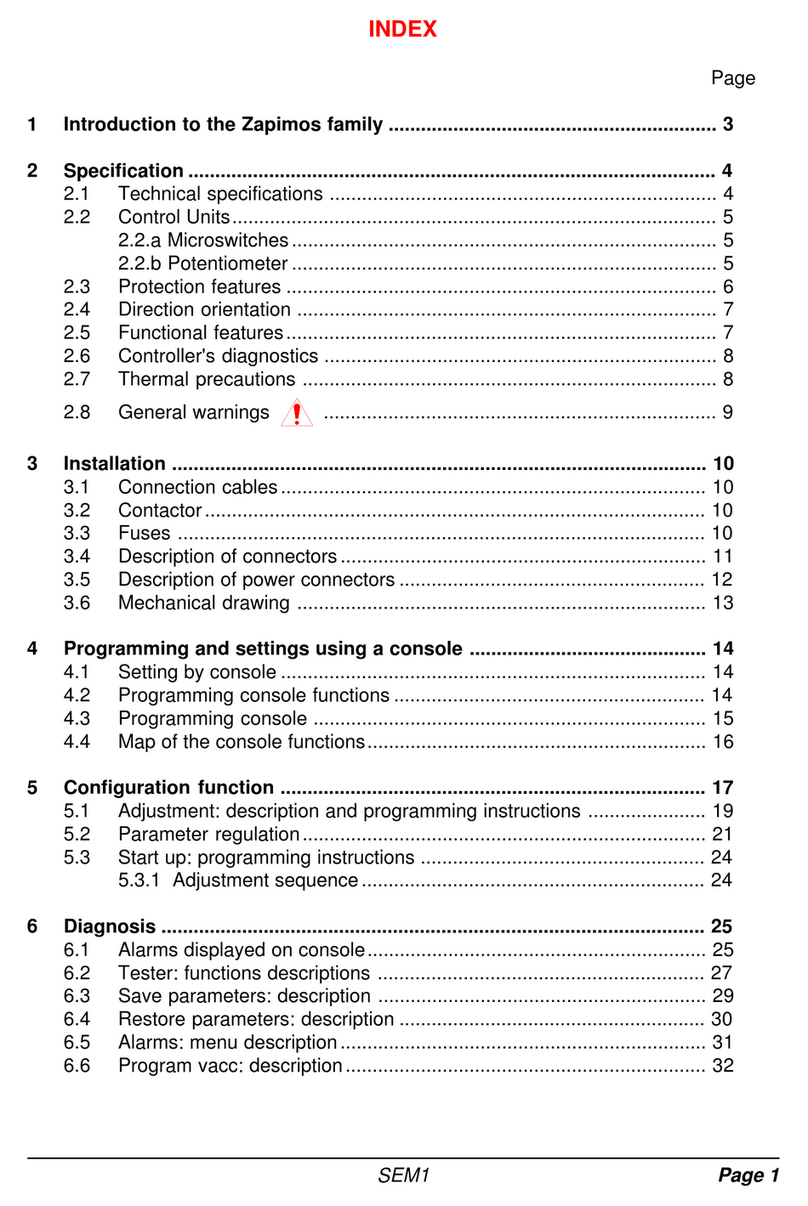

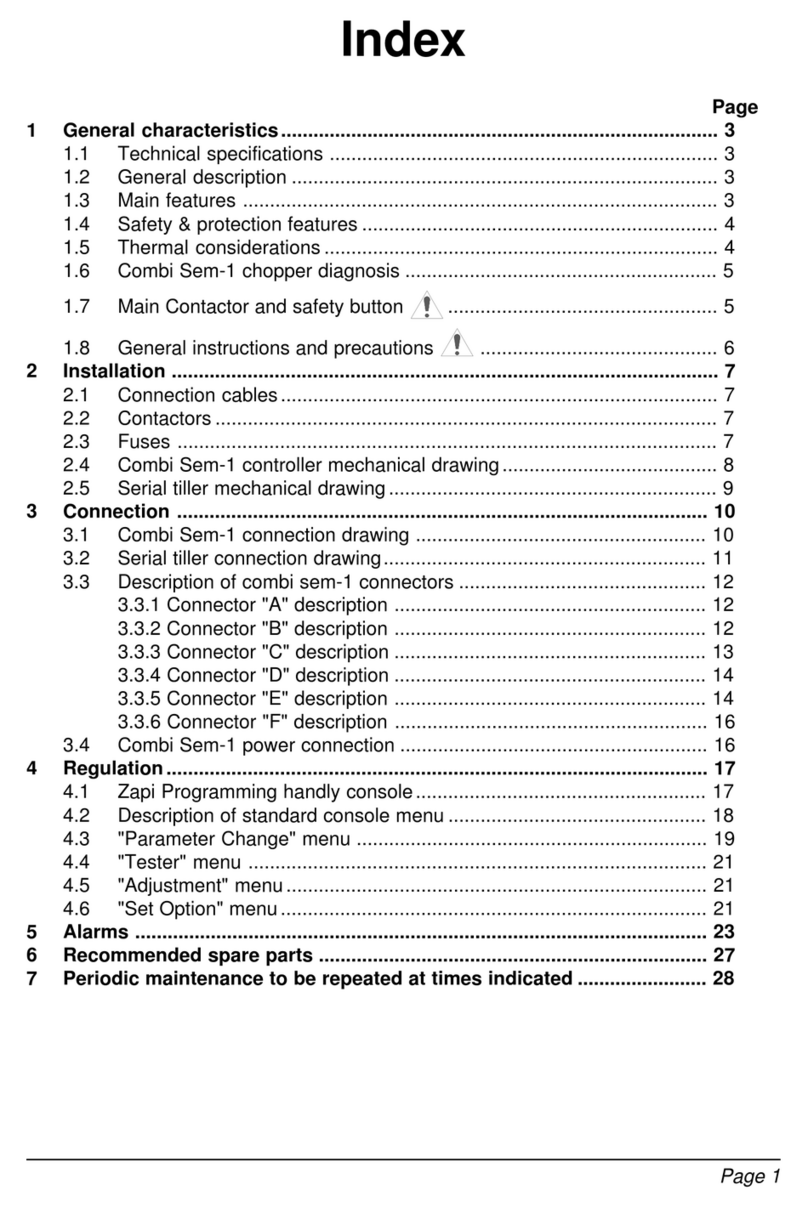

Contents

1INTRODUCTION TO ZAPI CAN SYSTEM............................................................................5

2GENERAL CHARACTERISTIC ............................................................................................6

2.1 Functional characteristics ...........................................................................................6

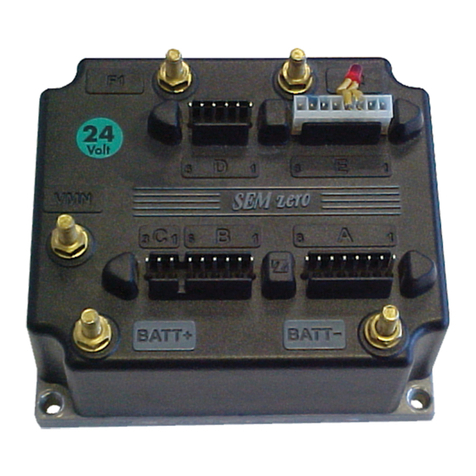

2.2 Input............................................................................................................................6

3INSTALLATION HINTS.........................................................................................................7

3.1 Material overview........................................................................................................7

3.1.1 Connection cables ........................................................................................7

3.1.2 Fuses............................................................................................................7

3.2 Installation of the hardware.........................................................................................7

3.2.1 Wirings: CAN connections and possible interferences.................................8

3.2.2 Wirings: I/O connections.............................................................................10

3.2.3 Insulation of truck frame..............................................................................10

3.3 Protection and safety features..................................................................................10

3.3.1 Protection features......................................................................................10

3.3.2 Safety Features...........................................................................................11

3.4 EMC..........................................................................................................................11

4OPERATIONAL FEATURES ..............................................................................................14

5DESCRIPTION OF THE CONNECTORS............................................................................15

5.1 Connector CNA: ZAPI Minifit 22 poles......................................................................15

5.2 Connector CNB: ZAPI Minifit 6 poles........................................................................15

5.3 Connector CNC: ZAPI Minifit 6 poles .......................................................................15

5.4 Connector CND: ZAPI Minifit 4 poles .......................................................................16

5.5 Connector CNE: ZAPI Minifit 8 poles........................................................................16

5.6 Connector CNF: ZAPI Minifit 10 poles......................................................................16

5.7 Connector CNG: ZAPI Minifit 16 poles .....................................................................17

6DRAWINGS.........................................................................................................................18

6.1 Mechanical drawing..................................................................................................18

6.2 Functional drawing....................................................................................................19

7PROGRAMMING & ADJUSTMENTS USING DIGITAL CONSOLE...................................20

7.1 Adjustments via console...........................................................................................20

7.2 Description of console and connection.....................................................................20

7.3 Description of standard console menu .....................................................................21

7.4 Description of programmable functions (options) .....................................................22

7.5 Description of parameters that may be programmed (parameter change)...............24

7.6 Adjustments table .....................................................................................................25

7.7 Description of the tester function ..............................................................................27

7.8 Description of the console save function..................................................................30

7.9 Description of the console restore function...............................................................30

7.10 Description of the set model Function ......................................................................31

7.11 Description of alarms menu......................................................................................33

8CONTROLLER DIAGNOSTIC ............................................................................................34

8.1 Analysis of alarms displayed on the console............................................................34

9RECOMMENDED SPARE PARTS FOR CONTROLLER...................................................35

10 PERIODIC MAINTENANCE TO BE REPEATED AT TIMES INDICATED.........................36