Page - 4/95 AEMZP0BA - EPS-AC0 - User Manual

8.8 Safety features .........................................................................................................34

8.9 EMC .........................................................................................................................34

8.9.1 Emission.....................................................................................................35

8.9.2 Electromagnetic Immunity ..........................................................................35

8.9.3 ESD............................................................................................................35

8.10 Fighting the dither.....................................................................................................36

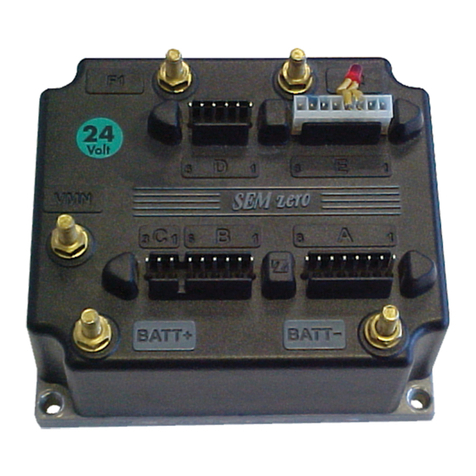

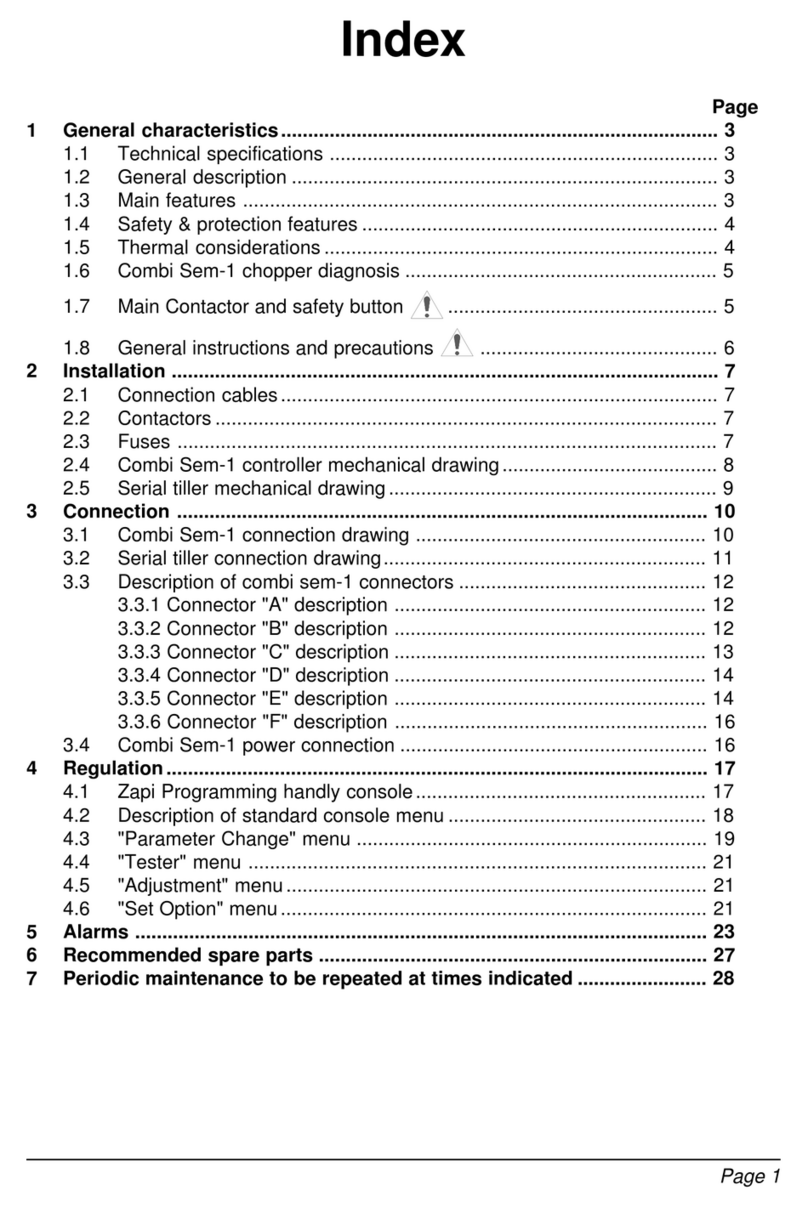

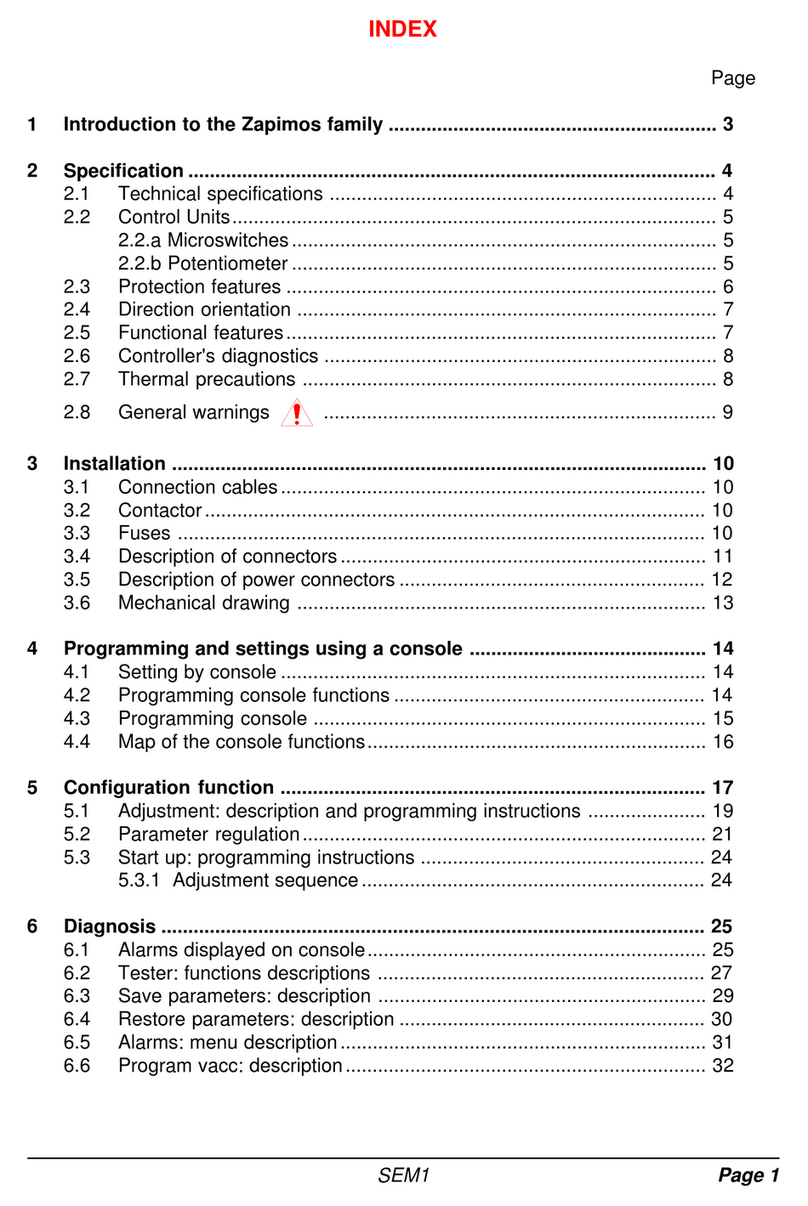

9DESCRIPTION OF THE CONNECTORS ...........................................................................38

9.1 Connectors of the logic.............................................................................................39

9.1.1 CNA connector...........................................................................................39

9.1.2 CNB connector...........................................................................................39

9.1.3 CNC connector...........................................................................................40

9.2 Description of power connections ............................................................................41

10 INSTALLATION PROCEDURE ..........................................................................................42

10.1 Twin Pot with Encoder and Feedback pot: one shot installation procedure.............42

10.2 Twin Pot with Encoder, Straight Ahead Switch and Feedback pot: one shot installation

procedure.................................................................................................................43

10.3 Stepper Motor with Encoder and Feedback pot: one shot installation procedure....45

10.4 Stepper Motor with Encoder and Toggle Switch(es): one shot installation procedure46

11 SETTING THE EPS-AC0 ....................................................................................................49

11.1 Complete set-up description.....................................................................................49

11.1.1 Stepper Motor only.....................................................................................49

11.1.2 Stepper Motor & AUTC...............................................................................49

11.1.3 RTC (Twin Pot) only...................................................................................49

11.1.4 RTC & AUTC..............................................................................................50

11.2 Quick set-up .............................................................................................................50

11.2.1 Stepper Motor only.....................................................................................50

11.2.2 Stepper Motor & AUTC...............................................................................51

11.2.3 RTC only or RTC & AUTC..........................................................................51

12 PROGRAMMAING & ADJUSTMENTS USING DIGITAL CONSOLE................................52

12.1 Adjustments via console...........................................................................................52

12.2 Description of console (hand set) & connection.......................................................52

12.3 Description of standard console menu.....................................................................53

12.3.1 Stepper motor with Encoder and Feedback pot.........................................54

12.3.2 RTC with Encoder and Feedback pot.........................................................55

12.3.3 Stepper motor with Encoder and Toggle switch(es)...................................56

12.4 Function configuration..............................................................................................57

12.4.1 Config menu “SET OPTIONS” functions list...............................................58

12.4.2 Config menu “ADJUSTMENTS” functions list ............................................62

12.4.3 Config menu “SET MODEL” functions list..................................................65

12.4.4 Main menu “PARAMETER CHANGE” functions list...................................68

12.4.5 Zapi menu “HARDWARE SETTINGS” functions list ..................................75

12.4.6 Zapi menu “SPECIAL ADJUSTMENT” functions list..................................76

12.4.7 Main menu “TESTER” functions list ...........................................................78

13 OTHER FUNCTIONS..........................................................................................................82

13.1 Acquiring the Motor resistance.................................................................................82

13.2 Alignment at the rest position...................................................................................82

13.3 Straight ahead steering numbness...........................................................................82

13.4 Special Debugging and Troubleshooting system.....................................................83

14 EPS-AC0 ALARMS LIST....................................................................................................84