Page 1

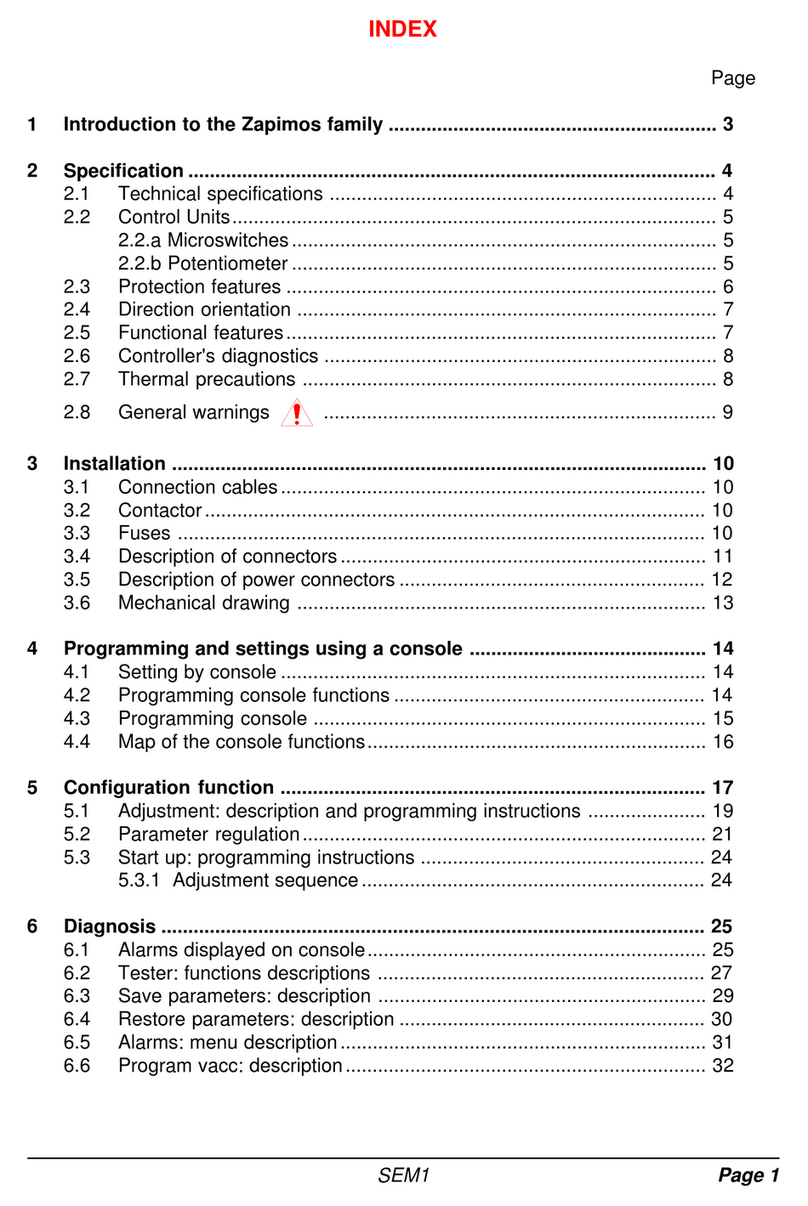

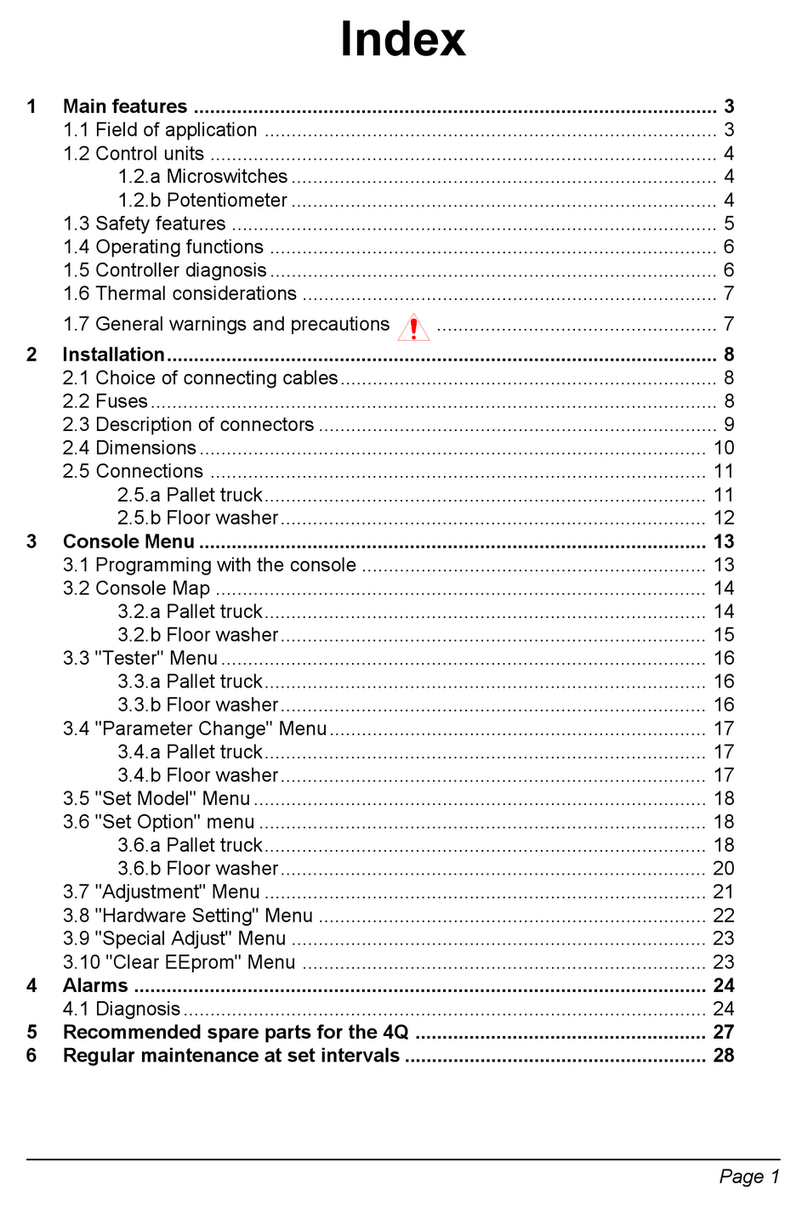

Index

Page

1 General characteristics................................................................................. 3

1.1 Technical specifications ........................................................................ 3

1.2 General description ............................................................................... 3

1.3 Main features ........................................................................................ 3

1.4 Safety & protection features.................................................................. 4

1.5 Thermal considerations......................................................................... 4

1.6 Combi Sem-1 chopper diagnosis .......................................................... 5

1.7 Main Contactor and safety button .................................................. 5

1.8 General instructions and precautions ............................................ 6

2 Installation ..................................................................................................... 7

2.1 Connection cables................................................................................. 7

2.2 Contactors............................................................................................. 7

2.3 Fuses .................................................................................................... 7

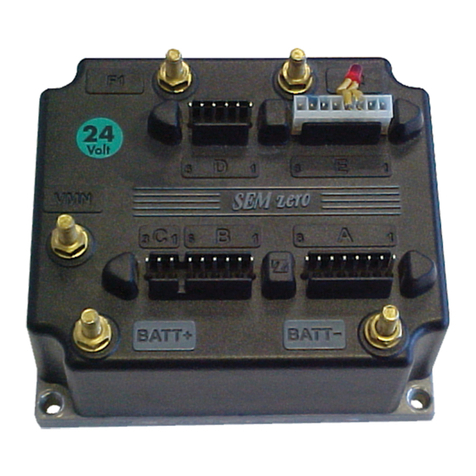

2.4 Combi Sem-1 controller mechanical drawing........................................ 8

2.5 Serial tiller mechanical drawing............................................................. 9

3 Connection .................................................................................................. 10

3.1 Combi Sem-1 connection drawing ...................................................... 10

3.2 Serial tiller connection drawing............................................................ 11

3.3 Description of combi sem-1 connectors .............................................. 12

3.3.1 Connector "A" description .......................................................... 12

3.3.2 Connector "B" description .......................................................... 12

3.3.3 Connector "C" description .......................................................... 13

3.3.4 Connector "D" description .......................................................... 14

3.3.5 Connector "E" description .......................................................... 14

3.3.6 Connector "F" description .......................................................... 16

3.4 Combi Sem-1 power connection ......................................................... 16

4 Regulation.................................................................................................... 17

4.1 Zapi Programming handly console...................................................... 17

4.2 Description of standard console menu................................................ 18

4.3 "Parameter Change" menu ................................................................. 19

4.4 "Tester" menu ..................................................................................... 21

4.5 "Adjustment" menu.............................................................................. 21

4.6 "Set Option" menu............................................................................... 21

5 Alarms .......................................................................................................... 23

6 Recommended spare parts ........................................................................ 27

7 Periodic maintenance to be repeated at times indicated ........................ 28