1:

Instructions

For

Operation

BEFOREOPERATION

I.illtil!

~

*:bn

i1fl

~:lf'fm:rf

:$

o

2.tJL~~~ll'.J-,

.M....t.tffi7'HJ!tl~~[fl]E\I1;J~!Jt#:/J[fl],

tt~'

:lf'~~{f!J~o

3.1±~-

r.J

<P,

:;r:;~-m.m:k.R.

-t~1'1!7J!JtJL&:w!ffi

o

4.li}i'JiA.

101!

7#JtJLtjMJ._t.P.Jft~

l'f!ff.l)t;f§

f:IT.~~

.iE

1i}ij

0

l.N

ever

operate

the

machine

unless

its

oil

pan

has

been

filled

with oil.

2.After

setting

up

the

maching,check

the

direction

of

motor

rotation.

to

check

it,

turn

the

handwheel

by

hand

to

bring

the

needle

down,

and

turn

the

power

switch

ON

while

observing

the

handwheel.(The

hand

wheel

should

turn

counterclockwise

as

observed

from

the

handwhee1

side.)

3.Do

not

use

a

lager

motor

pulley

for

the

first

cme

mouth.

4.Confirm

that

the

voltage

and

phase

(single

Jr

3-phase)are

correct

by

checking

them

against

the

ratings

showm

on

the

motor

namaeplate.

OPERATION

PRECAUTIONS

l.*:im

1'1!~7f3CE.JGtJL:H:iE~llt,

itii.P~'f-;li)(:¥Utt-a':rFl'!l5o

2.tJL~~~!Jt,

iJ!f0J~'f-~{$.A:f}6~;fHP~~o

3.tJL*lllll~liUIF-=:114&:wat,

-JE~-13J1lj)fJt:fJL7f3Co

4.:f*fl:::f;\!g:7HIL~Ilt,

~'m-ImE!Yflt7N.o

s.m~~~WHEil,

tt~/Gfti'fffW.Aa9*E.lG=¥-l~U.iZ.fffiii*W$ur_t~

"V"

%&:'~if,

~~!ffi;f!li'f!~:fJLc

6./l'*.fflW~7k~il!l7*:fffl-!f.f5fiJ:J~HJ!GtJL~~i'lil

o

LKeep

your

hands

away from

the

needle

when you

turn

the

power

switch

ON

or

while

the

machine

is

operating.

2.Do

not

put

your

fingers

into

the

thread

take-up

cover

while

the

machine

is

operating.

3.Be

sure

to

turn

the

power

switch

OFF

before

tilting

the

machine

head

or

removing

the

V

belt.

4.

When

an

operation

leaves

from

the

machine,

make

sure

to

turn

off

the

power.

5.During

operator,be

careful

not

to allow your

or

any

other

person's

head

or

heads

to come

close

to

the

hand

wheel,

vbelt,bobbin

winder

or motor or motor.Also,do

n<·t

place

anything

close

to

them.Doing

so may

be

dangerous.

6.Don't

clean

the

face

of

machine

head

with

thinner.

1.*Jlwi¥-J~~(I~l1

...

~2

...

~3

...

~4)

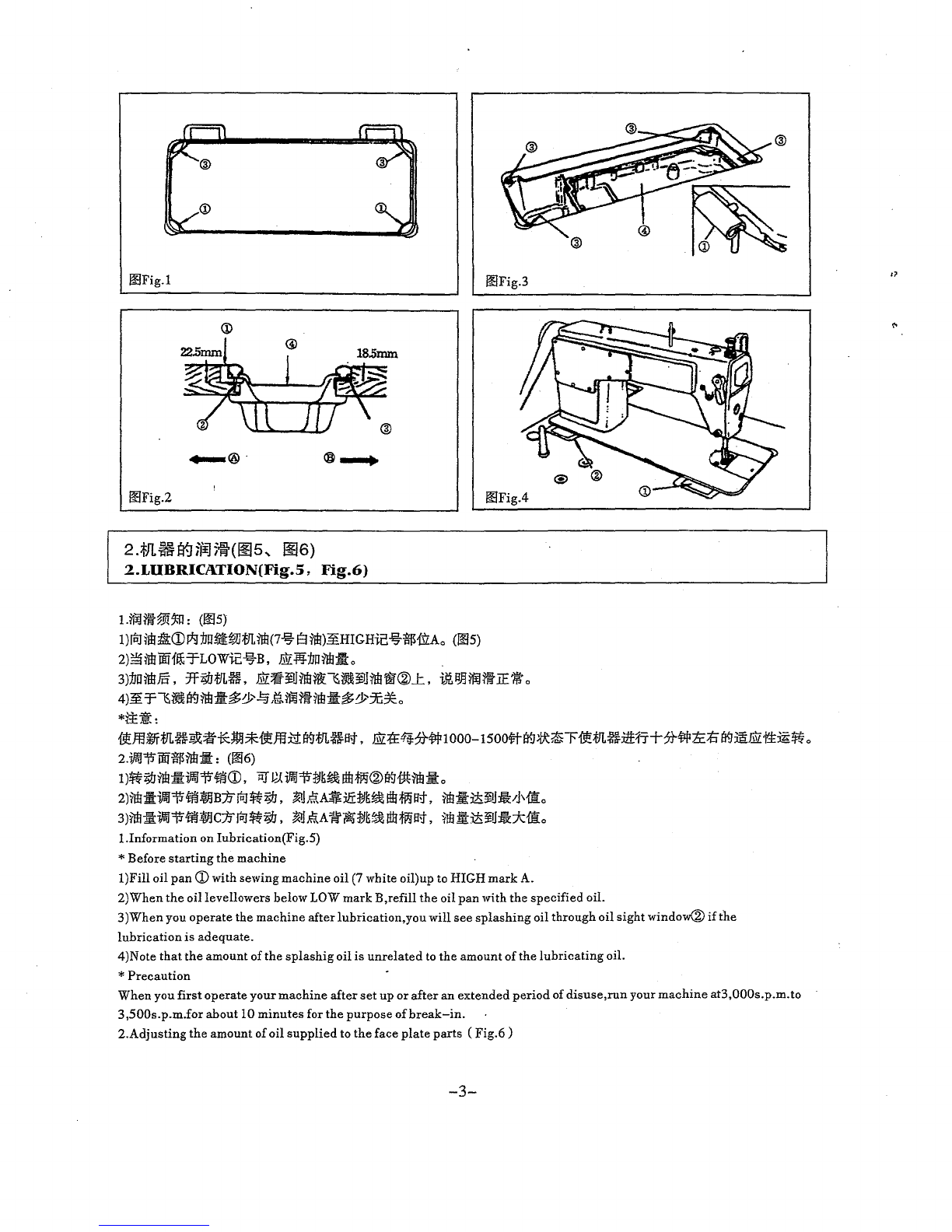

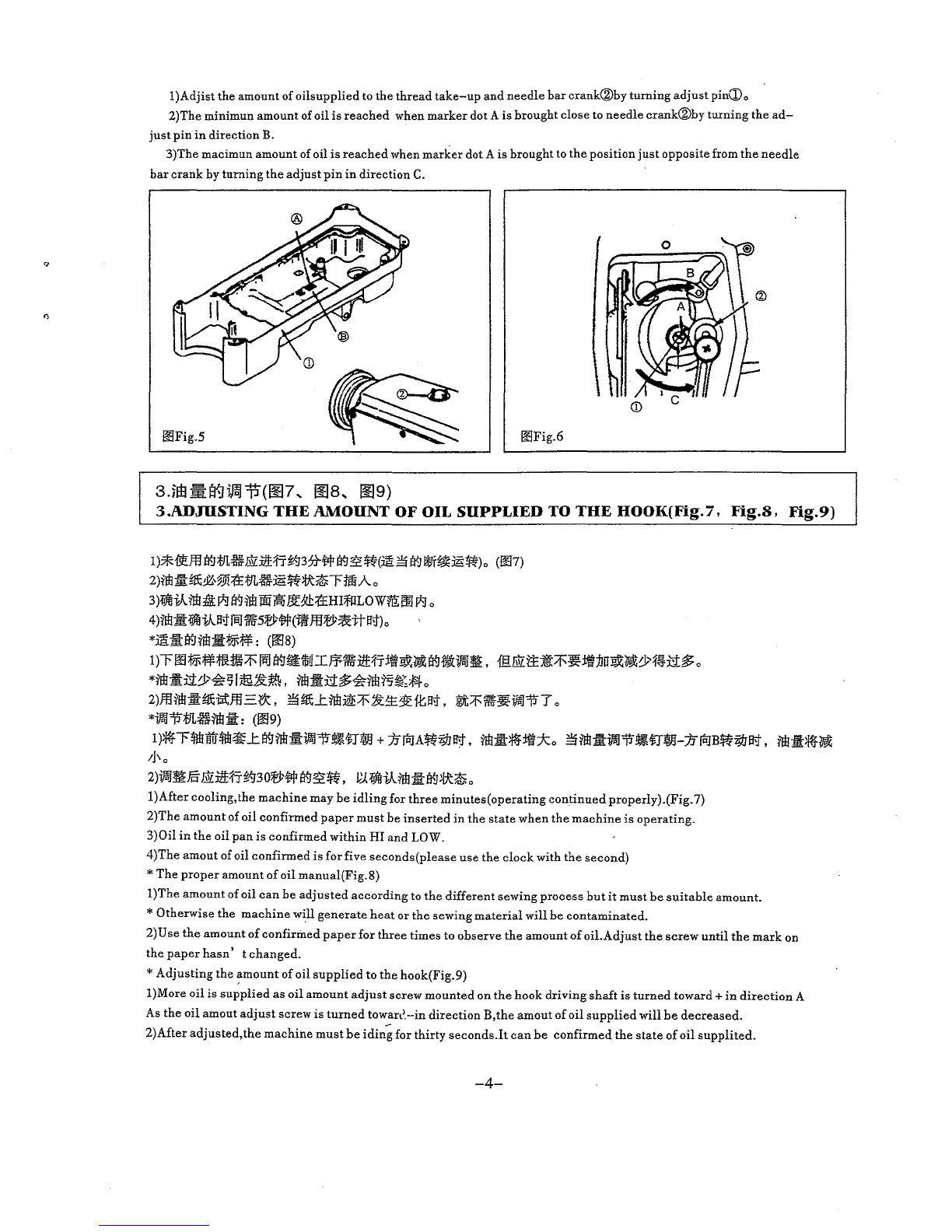

l.INSTALLATION{Fig.l,

Fig.2,

Fig.3,

Fig.4)

*¥cl!fiil:3'<~:

1)

¥!llfiil:Ellm!tEI

fti:t

[!!];ft\\i!mJ§

c

2)

:imOO.P.Jr1.K,

*tWJ7JjJ:!!fiil:j:J*CD.ffl¥J:!!:&:J.i~®~JEtEA-:IiL(tllt*fl:fl:::f-)ft),

~WJ.Rilfl:&:J*1/J®.ffl¥i:!!fiil:J*~®

l§J

JEtEB-)ft(ffl

:tlL~:ii*~*.g--)ft),

~)§

jfl

irll

fiil:@;/i)(:tf;¢

..t.

c (f!i1

1!12)

3)

)j1J.tJL~:li:m~CD;Ii)(:.AJE:i:f1fl'Lri3,

.!:Ji:t:t&astJL~:li:m~J*®ff!W(~,

~~tJL~~J

lmRt¥1

J:i9t!L~J*1/J®

..

L

(1!13

1!14)

"

Installing

the

oil

pan

1

)The

oil

pan

should

rest

on

the

four

corners

of

the

machine

table

groove.

2)Fix

two

rubber

seats

CDon

side

A(

operator's

side

)using

nails®as

illustrated

above.Fix

two

cushion

seats®

on

side

B(hinged

side)using

nails®.

Then

place

oil

pan@on

the

fixed

seats.(Fig.l

,Fig.2)

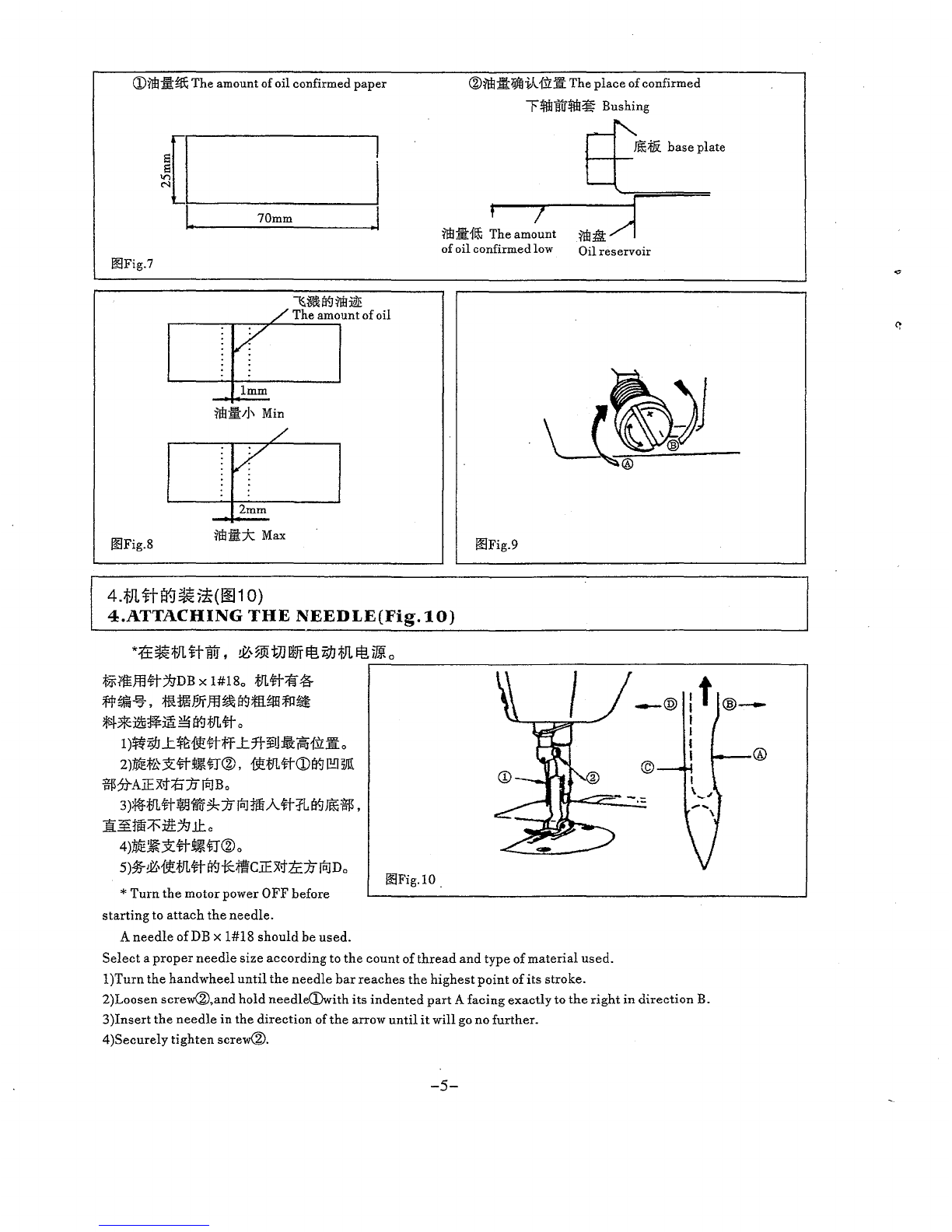

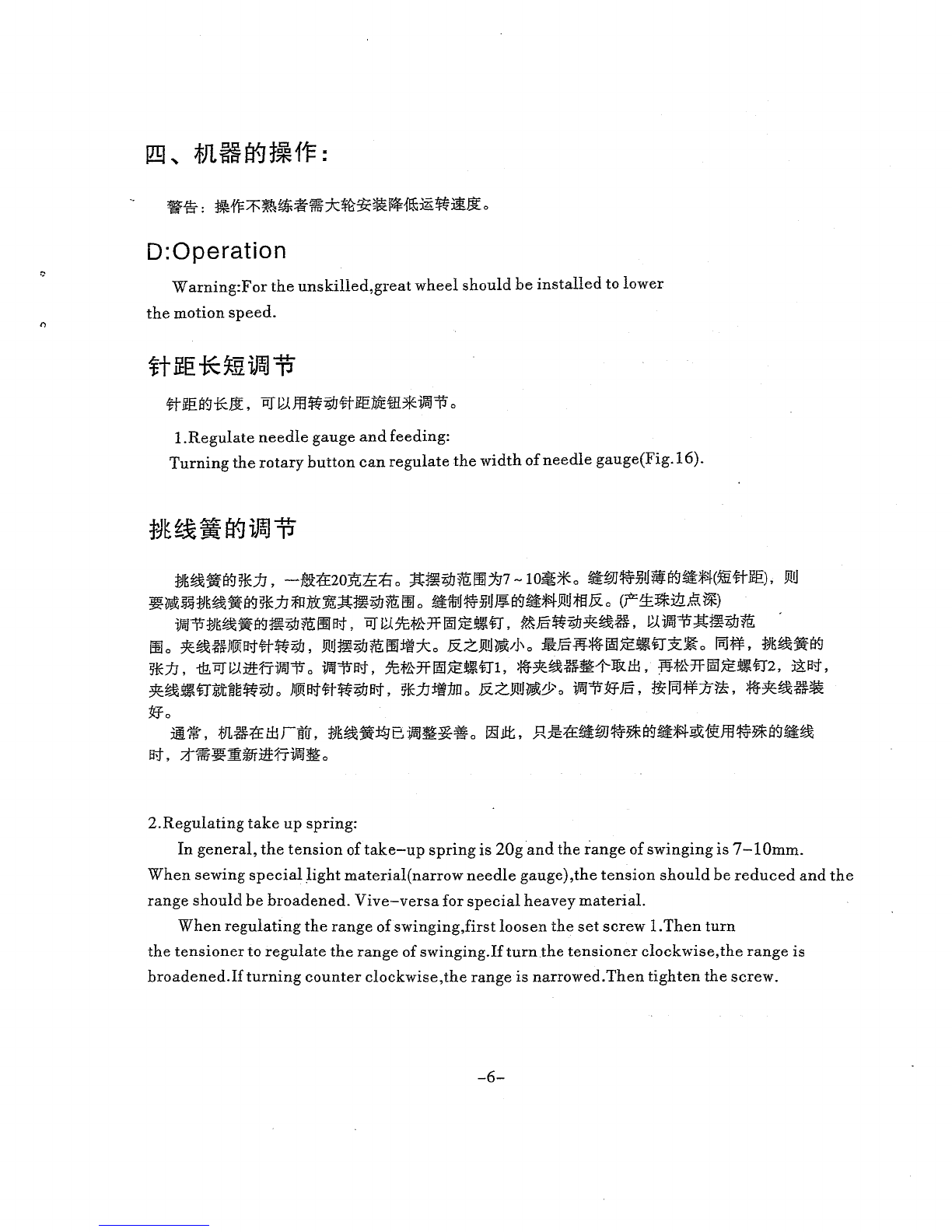

3)Fix

hingeCDinto

the

opening

in

the

machine

bed,

and

fit

the

machine

head

to

table

rubber

hinge\])before

placing

the

machine

head

on

cushions®on

the

four corners.(:<ig.3,Fig.4)

-2-