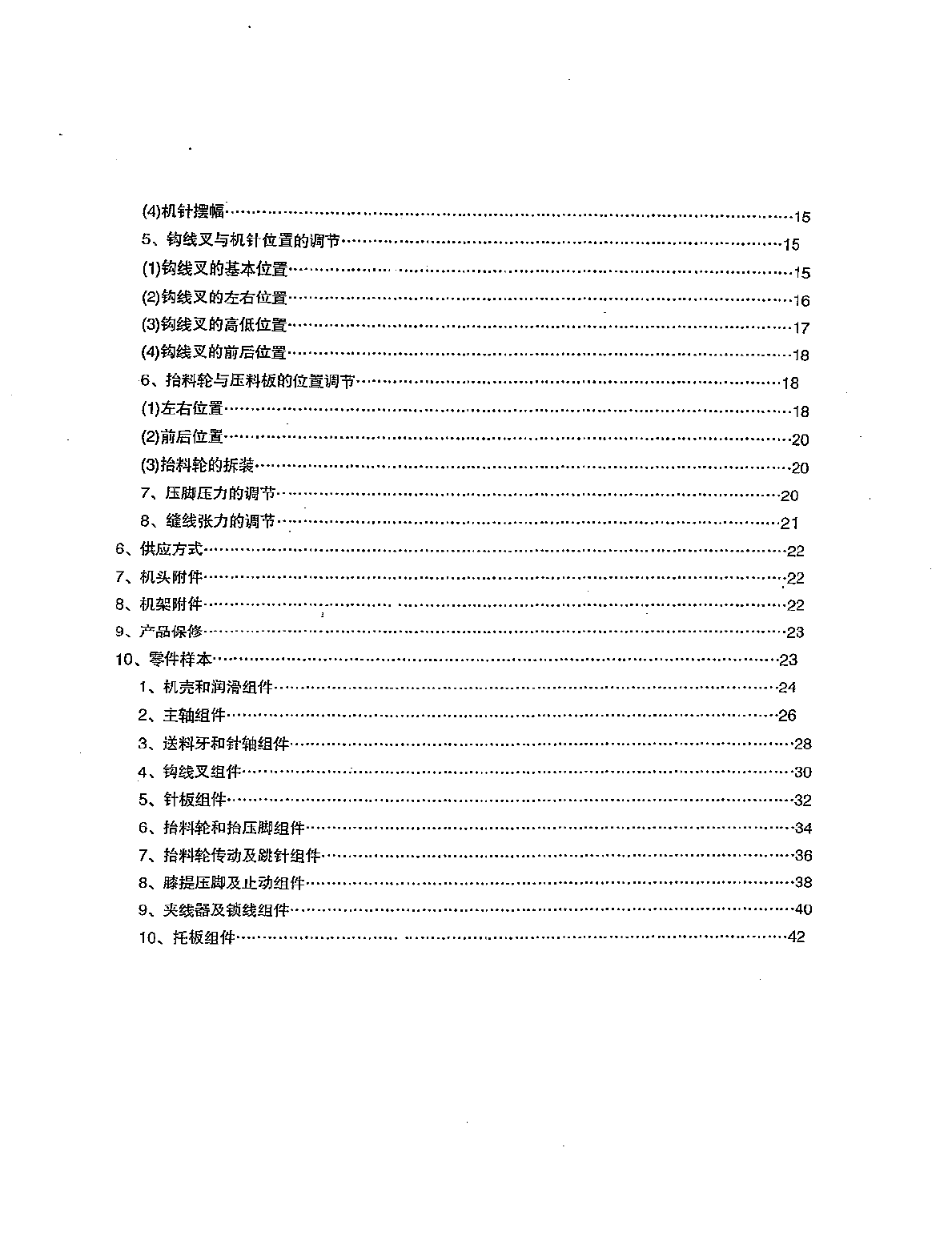

TABLE OF CONTENTS

ForeWord····································

..

···············································································1

1.

Brief lntroducion to The MOd8J·································•••·····•·········••··········•••·············••··· 2

2.

Main

TeChnical

Specifications···················································································· 2

3.

Mdachine Installation and Operation Preparation····················...

·····································

3

1.

Machine

installation·································································································3

(1)Unpacklng machine

head·······················································································

4

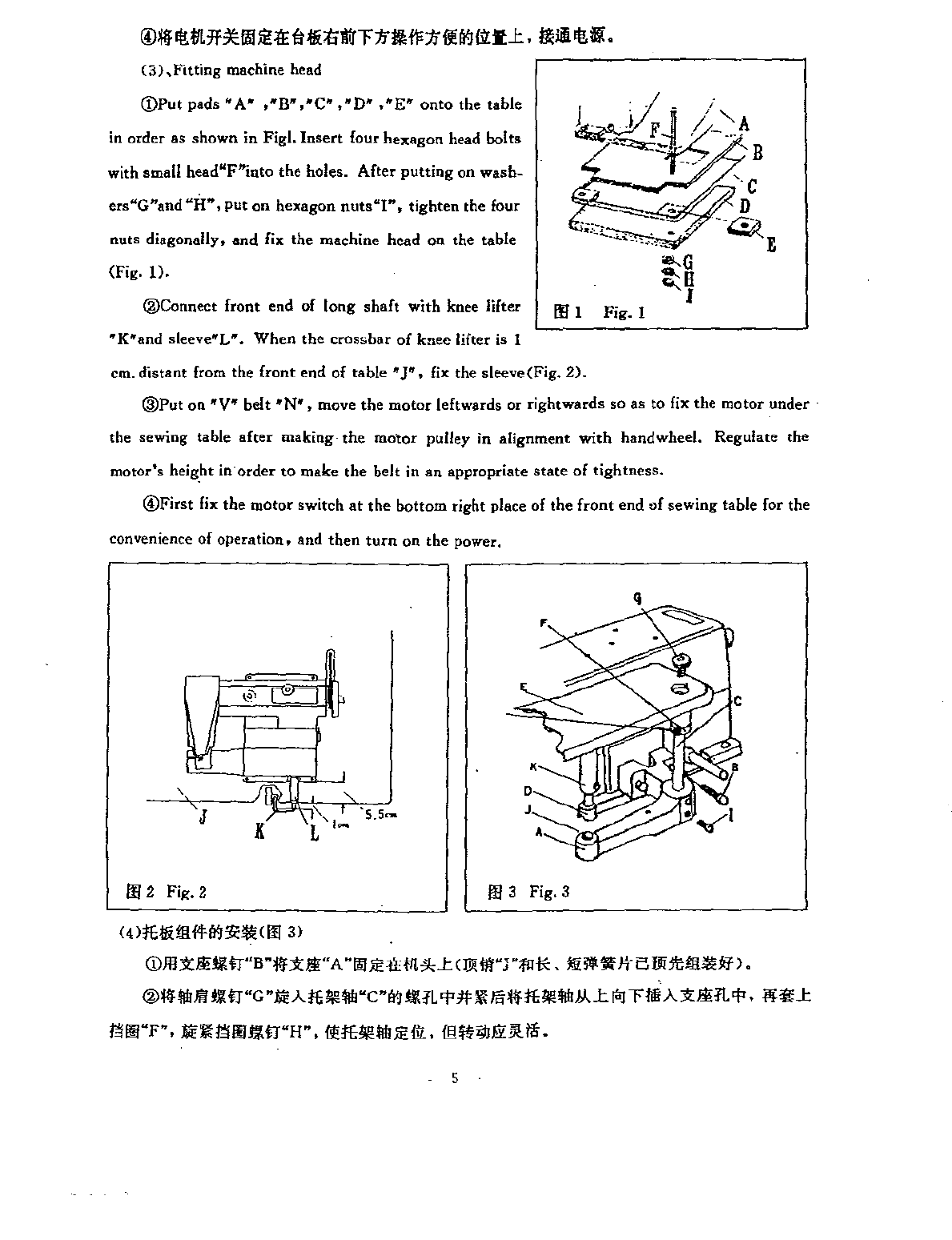

(2)Fitting machine

franme·····························································································4

(3)Fitting

machine

head·························································································

..·· 5

(4)Fitting

Work

plate components

.................................................................................

6

2.

Operation preparation

.............................................................................................

6

(1)Cieaning·······································

........................................................................

6

(2)lnspection·····················································..

··································"··········

..

·····

6

{3)Lubrication··············

............

,

.................................................................................

7

4. Opeation the Machine--·.......·.....·........·........·........····.....·.....·..·.....·.....·.....·..·............·7

1.

Rotating direction and sewing speed

of

main

shaft···--···

..............................................

7

2. Needle selection--..·..·

..

·..·..·.....··....·.....·...........·...........·..·--·.....·

..

··----·

..

··....·.....·····8

3.

Specifications--.....·.....·..·........·.....·.....·...

··

...·..·.....·.....·--·........·...........·...........·...·8

4. Needle replacemet--.....·..·.....·..·

..

·...........·.....·........·.....·

....................

·...........·..·

----8

5.

Threading········......

·································

...·········...···············......

························

·9

6. Feeding and

pulling

out

of

sewn materials

..................................................................

g

7.

Skip

stitch device··........·........··....·.....····

..

·.....·.....·..·.....··.......··....·.....····

..

·........··

10

8. Regulating feed dogs height··.....·

....

·.....·........·..·............·..·..·.....·.....·.....·......···...·

10

5. Adjustment

of

the Machine··

..

·..·..·.....·.....·

..

····........··.......·.....·..·..·...........·.....·.....·...·

11

1. Regulation

of

stitch length··--

................................................................................

11

2. Adjustmen

of

blindstitch sewing penetration--

.............................................................

12

3.

Regulation

of

the pressure

of

material retainer·...........·

..........................................

--12

4. Position regulation

of

needle and needle plate

........................................................

:--·13

(1)The front and the rear

of

position··---

......................................................................

13

(2)The positioning

of

location·····--·--··--......................................................................

14

(3)The

left

limit

position

of

the needle

...........................................................................

14

From the library of: Superior Sewing Machine & Supply LLC