3M™Personal Safety Division | 3M™Particulate Respirators 8825+ and 8835+

Version: 1

This version is the sole document applicable to the product(s) since its date of publication

Warnings and Use Limitations

ŔAlways be sure that the complete product is:

– Suitable for the application;

– Fitted correctly;

– Worn during all periods of exposure;

– Replaced when necessary.

ŔProper selection, training, use and appropriate

maintenance are essential in order for the product to help

protect the wearer from certain airborne contaminants.

Failure to follow all instructions on the use of these

respiratory protection products and/or failure to properly

wear the complete product during all periods of exposure

may adversely aect the wearer’s health, lead to severe or

life threatening illness or permanent disability.

ŔFor suitability and proper use follow local regulations,

refer to all information supplied or contact a safety

professional/3M representative.

ŔBefore use, the wearer must be trained in use of the

complete product in accordance with applicable Health and

Safety standards/guidance.

ŔThese products do not contain components made from

natural rubber latex.

ŔThese products do not protect against gases/vapours.

ŔDo not use in atmospheres containing less than 19.5%

oxygen. (3M denition. Individual countries may apply their

own limits on oxygen deciency. Seek advice if in doubt).

ŔDo not use for respiratory protection against atmospheric

contaminants/concentrations which are unknown or

immediately dangerous to life and health (IDLH).

ŔDo not use with beards or other facial hair that may

inhibit contact between the face and the product thus

preventing a good seal.

ŔLeave the contaminated area immediately if:

– Breathing becomes dicult.

– Dizziness or other distress occurs.

ŔFor single shift use or reusable devices: Discard and replace

the respirator if it becomes damaged, breathing resistance

becomes excessive or at the end of the shift*.

*The respirators are re-usable and can be cleaned and used

for more than one shift.

ŔNever alter, modify or repair this device.

ŔBefore initial use, always check that the product is within

the stated shelf life (use by date).

Fitting Instructions

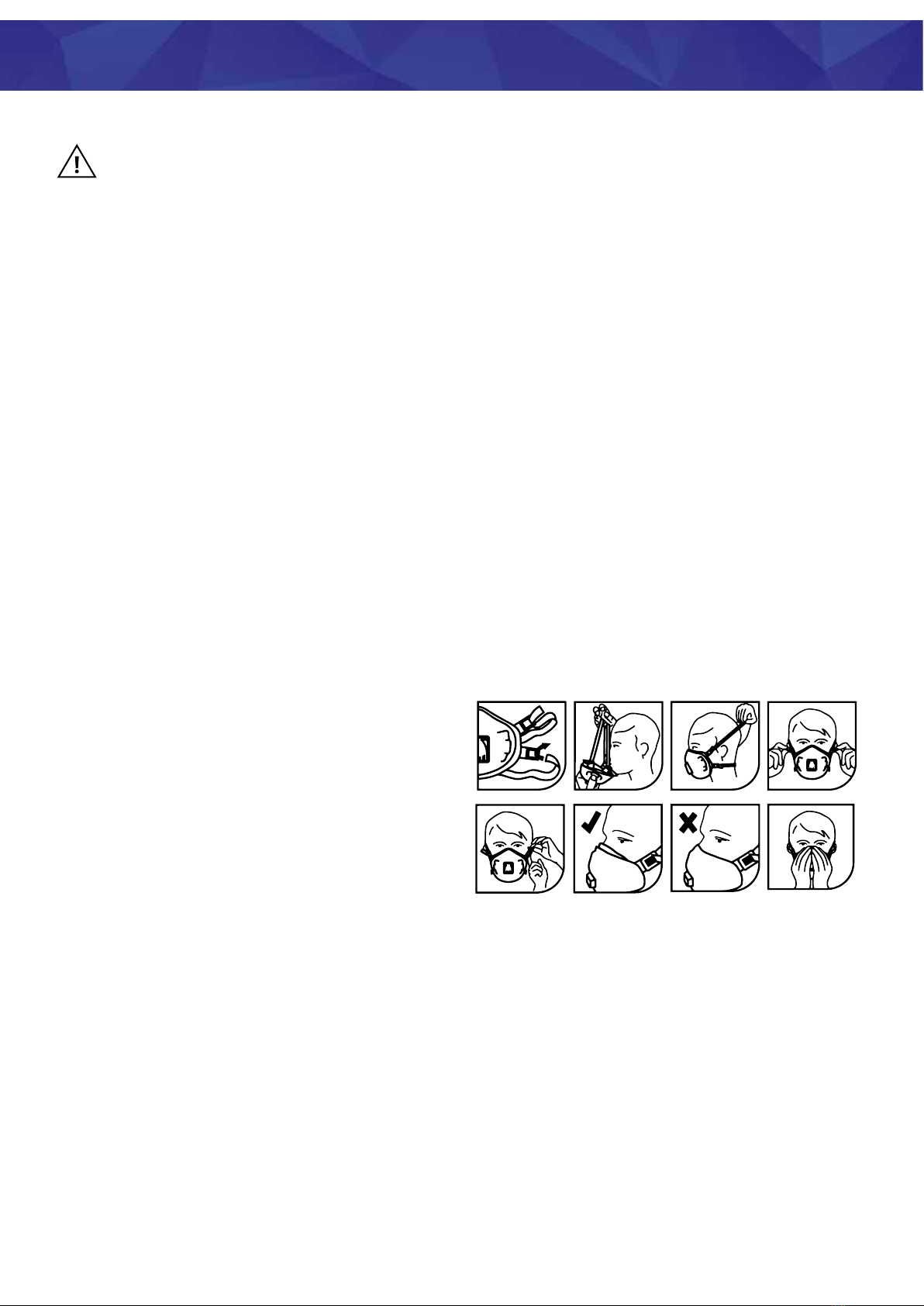

See Figure 1.

Before tting device, ensure hands are clean.

All respirator components should be inspected for damage

prior to each use.

1. Thread top elastic strap through top buckles. Repeat for

bottom strap and buckles.

2. Hold respirator under chin, with nosepiece up.

3. Locate the upper strap across the crown of the head and

the lower strap below the ears. Straps must not be twisted.

4.

4A. Adjust tension: Increase - pull evenly on both ends of the

top/bottom straps.

4B. Adjust tension: Decrease - without removing respirator,

push out on the back of the buckles.

5.

5A. Ensure face seal is properly formed around the nose.

5B. The face seal must not be folded in.

6. The seal of the respirator on the face should be t-

checked before entering the workplace.

Fit Check

1. Cover the front of the respirator with both hands being

careful not to disturb the t of the respirator.

2. VALVED respirator - INHALE sharply.

3. If the air leaks around the nosepiece, re-adjust the

respirator and face seal upon the face to eliminate leakage.

Repeat the t check.

4. If air leaks at the respirator edges, adjust the tension of the

straps to eliminate the leakage. Repeat the above t check.

If you CANNOT achieve a proper t DO NOT enter the

hazardous area. See your supervisor.

Users should be t tested in accordance with national

requirements. For information regarding t testing

procedures, please contact 3M.

1 2 3 4A

4B 5A 5B 6

Figure 1