(English)

5

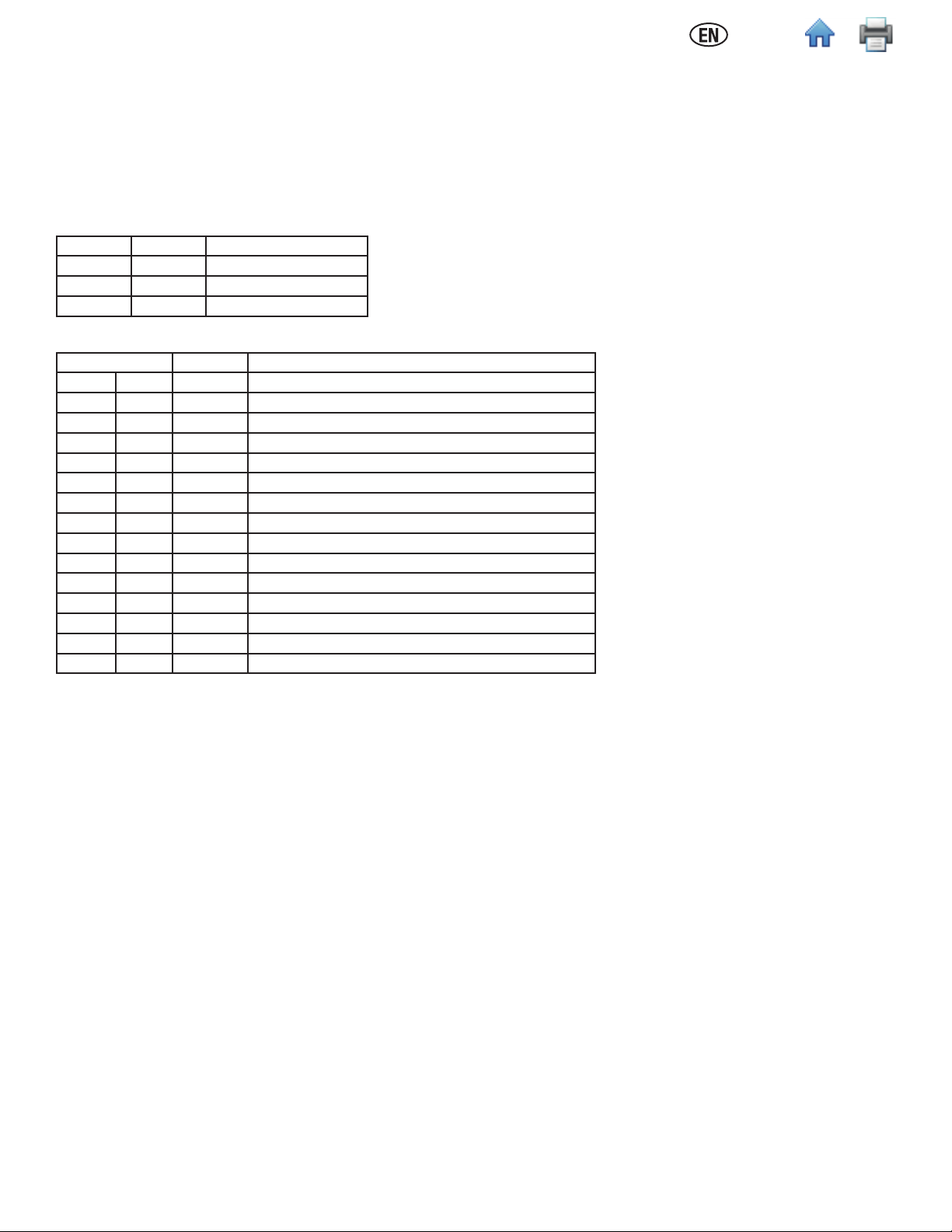

3M™ Cartridges 6000 Series (Side Mounted)

Number ****AAD Description NIOSH Approval for respiratory protection against the following contaminants

up to ten times the permissible exposure limit (PEL) when qualitatively t

tested, up to fty times the PEL when quantitatively t tested, and up to 1000

times the PEL when used in powered air-purifying or supplied air mode.

6001 07046 Organic Vapor Certain organic vapors

6001i Organic Vapor with Service Life

Indicator Certain organic vapors

6002 Acid Gas Chlorine, hydrogen chloride, and sulfur dioxide or chlorine dioxide or hydrogen

sulde.

6003 07047 Organic Vapor/Acid Gas Certain organic vapors, chlorine, hydrogen chloride, and sulfur dioxide or hydrogen

sulde or hydrogen uoride

6004 Ammonia/Methylamine Ammonia and methylamine

6005 Formaldehyde/Organic vapor Formaldehyde and certain organic vapors

6006 Multi-Gas/Vapor Certain organic vapors, chlorine, hydrogen chloride, chlorine dioxide, sulfur dioxide,

hydrogen sulde, ammonia/methylamine, formaldehyde or hydrogen uoride

6007 Mercury Vapor/Organic Vapor/Acid Gas Mercury vapor, certain organic vapors, sulfur dioxide, hydrogen sulde or chlorine

gas

60921 Organic Vapor/P100 Certain organic vapors and particulates

60921i Organic Vapor with Service Life

Indicator/P100 Certain organic vapors and particulates

60922 Acid Gas/P100 Chlorine, hydrogen chloride, and sulfur dioxide or chlorine dioxide or hydrogen

sulde and particulates

60923 Organic Vapor/Acid Gas/P100 Certain organic vapors, chlorine, hydrogen chloride, and sulfur dioxide or hydrogen

sulde or hydrogen uoride and particulates

60924 Ammonia/Methylamine/P100 Ammonia and methylamine and particulates

60925 Formaldehyde/Organic Vapor/P100 Formaldehyde and certain organic vapors and particulates

60926 Multi-Gas/Vapor/P100 Certain organic vapors, chlorine, hydrogen chloride, chlorine dioxide, sulfur dioxide,

hydrogen sulde, ammonia/methylamine, formaldehyde or hydrogen uoride and

particulates

60927 Mercury Vapor/Organic Vapor/Acid Gas/

P100 Mercury vapor, certain organic vapors, sulfur dioxide, hydrogen sulde or chlorine

gas and particulates

60928 Organic Vapor/Acid Gas/P100 Certain organic vapors, chlorine, hydrogen chloride, and sulfur dioxide or hydrogen

sulde or hydrogen uoride and particulates1

**** AAD part numbers are catalog numbers only. NIOSH approved as PSD part numbers

13M recommended for use against methylbromide or radioiodine up to 5 ppm with daily cartridge replacement.

NOTE: Not NIOSH approved for use against methylbromide or radioiodine.

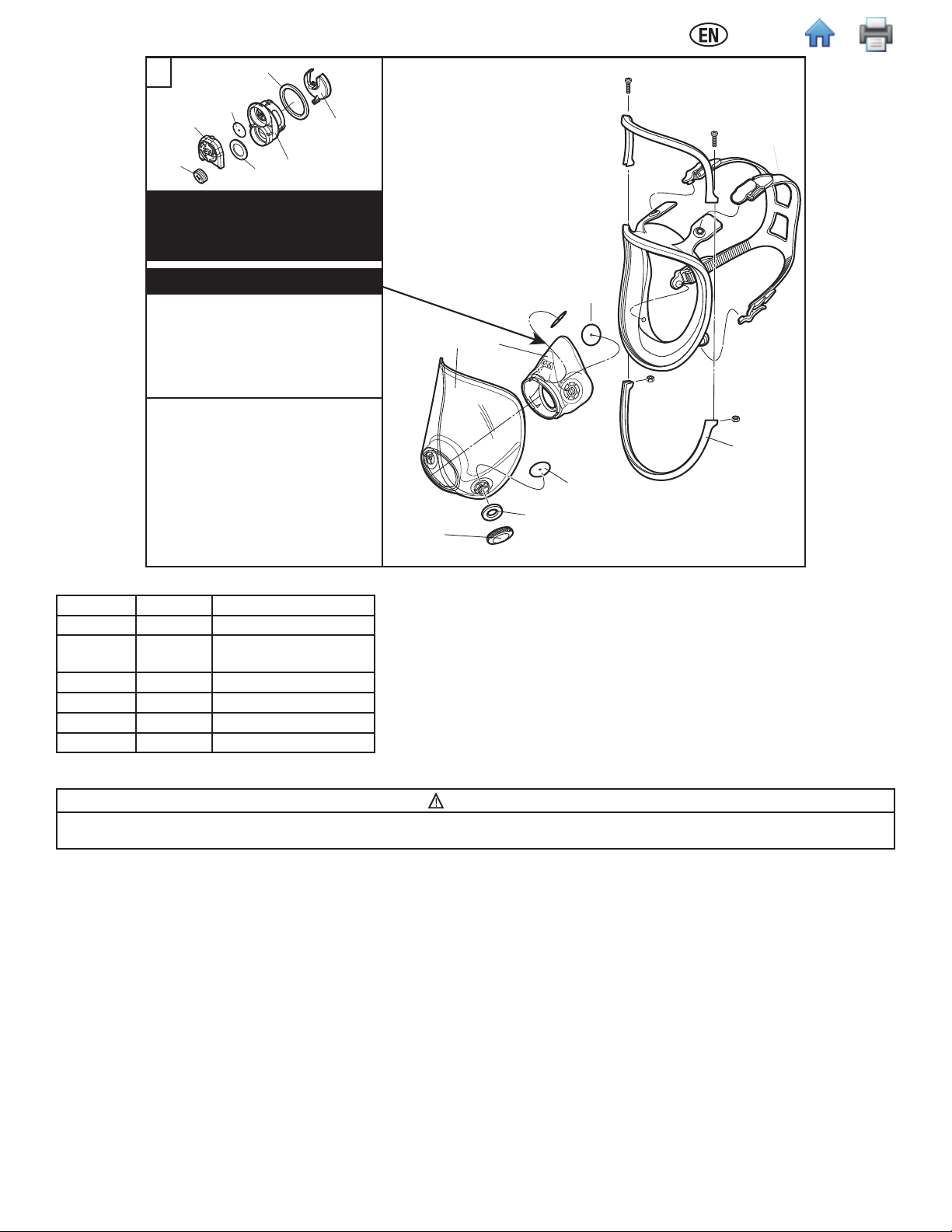

3M™ Filters (Side-Mounted), Adapters and Retainers

Number ****AAD Description

501 07054 Filter Retainer for Filters 5N11 and 5P71

502 Filter Adapter for Filters 2000 Series and 7093/7093C

2071 Particulate Filter, P95

2076HF Particulate Filter, P95, hydrogen uoride, with nuisance level acid gas relief1

2078 Particulate Filter, P95, 3M recommended ozone protection2, with nuisance level organic vapor/acid gas relief1

2091 07000 Particulate Filter, P100

2291 Advanced Particulate Filter, P100

2096 Particulate Filter, P100, with nuisance level acid gas relief1

2296 Advanced Particulate Filter, P100, with nuisance level acid gas relief1

2097 07184 Particulate Filter, P100, 3M recommended for ozone protection2, with nuisance level organic vapor relief1

2297 Advanced Particulate Filter, P100, 3M recommended for ozone protection2, with nuisance level organic vapor relief1

5N11 Particulate Filter, N95

5P71 07194 Particulate Filter, P95

7093 Particulate Filter, P100

7093C 37173 Particulate Filter, P100, hydrogen uoride, with nuisance level organic vapor/acid gas relief1

**** AAD part numbers are catalog numbers only. NIOSH approved as PSD part numbers