3359002 (A3-D-P) - Page 1 of 4

PSS 5000 Series

Self-contained breathing apparatus with Sentinel 7000 Instructions for Use

1 For your safety

1.1 General safety statements

● Beforeusingthisproduct,carefullyreadtheInstructionsforUse.

● StrictlyfollowtheInstructionsforUse.Theusermustfullyunderstandand

strictly observe the instructions. Use the equipment only for the purposes

speciedinthisdocument.

● DonotdisposeoftheInstructionsforUse.Ensurethattheyareretainedand

appropriatelyusedbytheproductuser.

● Onlyfullytrainedandcompetentusersarepermittedtousethisproduct.

● Complywithalllocalandnationalrulesandregulationsassociatedwiththis

product.

● Onlytrainedandcompetentpersonnelarepermittedtoinspect,repairand

service the product. Dräger recommends a Dräger service contract for all

maintenanceactivitiesandthatallrepairsarecarriedoutbyDräger.

● Properlytrainedservicepersonnelmustinspectandservicethisproductas

detailedintheMaintenancesectionofthisdocument.

● Use only genuine Dräger spare parts and accessories, or the proper

functioningoftheproductmaybeimpaired.

● Donotuseafaultyorincompleteproduct,anddonotmodifytheproduct.

● NotifyDrägerintheeventofanycomponentfaultorfailure.

● UseoftheapparatusshouldbeconsistentwithNFPA1500–Standardon

FireDepartmentOccupationalSafetyandHealthProgram.

● All approved respiratory equipment shall be selected, tted, used,

and maintained in accordance with MSHA (Mine Safety and Health

Administration),OSHA(OccupationalSafetyandHealthAdministration),and

otherapplicableregulations.

● Donotuseanyformofchemicalmarkingorpaintontheequipment.

● TheairsupplyshallmeettherequirementsforbreathingairaccordingtoCGA

G–7.1,GradeDorhigherqualityand,whereappropriate,beinaccordance

with:NFPA1989StandardonBreathingAirQualityforEmergencyServices

RespiratoryProtection.

● Beforeoccupationaluseof thisrespiratora writtenrespiratoryprotection

program must be implemented meeting all the local government

requirements.IntheUnitedStatesemployersmustcomplywithOSHA29

CFR1910.134whichincludesmedicalevaluation,training,andttesting.

CAUTION

This device has been tested and complies with the FCC (Federal

Communications Commission) rules. Changes or modications not

expressly approved by the manufacturer will void your authority to

operatethisproduct.

1.2 Denitionsofalerticons

Alerticons are usedin thisdocumentto provideand highlight textthat requires a

greaterawarenessbytheuser.Adenitionofthemeaningofeachiconisasfollows:

WARNING

Indicatesapotentiallyhazardoussituationwhich,ifnotavoided,could

resultindeathorseriousinjury.

CAUTION

Indicatesapotentiallyhazardoussituationwhich,ifnotavoided,could

result in physical injury or damage to the product or environment. It

mayalsobeusedtoalertagainstunsafepractices.

i

i

NOTICE

Indicatesadditionalinformationonhowtousetheproduct.

1.3 Trademarks

FPS® is a registered trademark of Dräger in the United States and/or other

countries.ContactDrägerfordetails.

Procell®and Duracell®areregisteredtrademarksofDuracellU.S.Operations,

Inc.intheUnitedStatesand/orothercountries.

Panasonic®isaregisteredtrademarkofPanasonicCorporation,Japaninthe

UnitedStatesand/orothercountries.

Dow Corning® and Molykote® are registered trademarks of Dow Corning

CorporationintheUnitedStatesand/orothercountries.

2 Description

2.1 Product overview

TheDräger PSS5000 Seriesisa compactand lightweightbreathing apparatus

thatprovidesthewearerwithrespiratoryprotectionusinganopen-circuit,pressure-

demand,compressed-airsystem.Theapparatuscanbeusedasaself-contained

system, or with an independent air supply for supplied-air respirator (SAR)

operations.TheseriesiscompatiblewithawiderangeofDrägercompressed-air

cylindersandfacemasks(e.g.FPS®7000facemasks,andaluminumorcomposite

cylinders).Theproductincludesthefollowingelectronicmonitoringsystems:

● ADrägerSentinel7000electronicmonitoringsystem,withintegralPASS

(personalalertsafetysystem).

● ADrägerwirelessHUD(head-updisplay)unit.

2.2 Feature description

The carrying system has a carbon-composite backplate, with adjustable

shoulderstrapsandwaistbeltconnectedusingquickreleaseconnectors.The

waist pad is connected at a exible joint to compensate for the twisting and

bendingoftheuser.

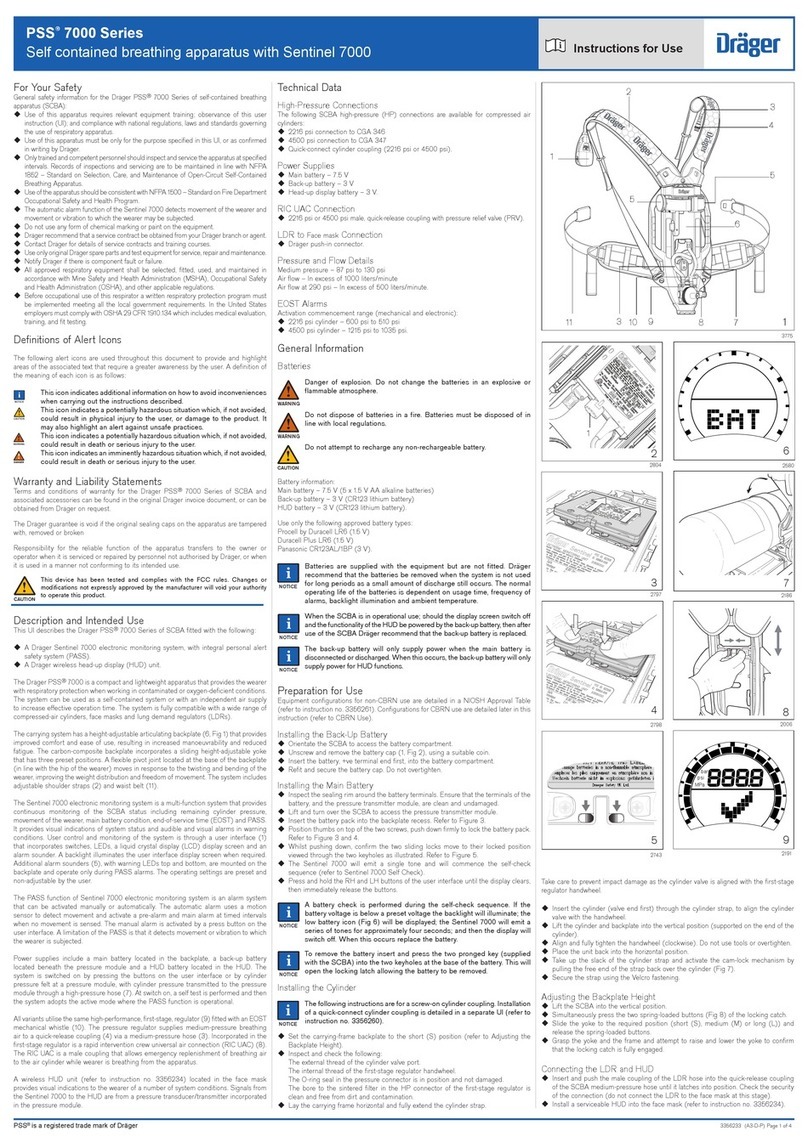

Allvariantsusethesamehigh-performancerst-stageregulator(Fig1,Item5)

ttedwithawhistlethatsoundsattheend-of-servicetime(EOST)(seeSection8

forthe EOSTactivationpressures).Theregulator suppliesmedium-pressure

breathing air through a medium-pressure hose (Fig 1, Item 6) and a quick

coupling (Fig 1, Item 2) to an attached lung demand regulator. Incorporated

intherst-stageregulatorisaRICUAC(rapidinterventioncrewuniversalair

connection)(Fig 1, Item 4),which is amale coupling that allowsemergency

rellingoftheaircylinderwhilewearerisbreathingfromtheapparatus.

The system is switched on by pressing the left and right buttons on the user

interface,orbycylinderpressurefeltatapressuremoduleinthebackplate,with

pressuretransmittedtothepressuremodulethroughahigh-pressurehose(Fig1,

Item3)whenthecylinderisopened.Atswitchon,theunitperformsaselfcheck,

and once the self check is passed, the system adopts the active mode where

theelectronicfunctionsareoperational.Duringtheselfchecksequence,theunit

scrollsthroughaseriesofscreensandprovidesstart-upinformationandoptions,

including:

● Themainbatterychargestate.

● Theelectronicleaktestoption.

● Thepersonalidentity(scrollingdata)option.

● Ifthesystemfailstheselfcheck,theunitprovidesfailsignalattheendof

thesequence.

ThePASSalarmcanbeactivatedmanuallyorautomatically.Themanualalarm

isactivatedbypressingtheyellowbuttonontheuserinterface(Fig2,Item2).

Theautomaticalarmusesamotionsensortodetectmovementandactivatesa

pre-alarmandmainalarmattimedintervalswhennomovementissensed.The

pre-alarmactivatesafter21-25secondswithoutmovement,andthemainalarm

activatesafterafurther8secondswithoutmovement.

ThewirelessHUDttedinthefacemaskprovidesvisualindicationsofsystem

conditions(seetheHUDInstructionsforUse3356234forfulldetails).Signals

fromtheSentinel7000totheHUDarefromapressuretransducer/transmitter

incorporatedinthepressuremodule.

System power supplies are the main battery in the backplate, the back-up

batteryinthepressuremoduleandtheHUDbatteryintheHUD.

A Dräger PC Link Module, congured to a Windows based PC software

package,isavailableasanoptionalaccessorythatallowswirelessreadingand

reprogrammingof the unit.The linkmodule allows reprogrammingthe system

operating settings, enabling additional functions, and downloading a record of

events(datalog).ContactDrägerforfulldetails.Thefunctions andparameters

describedinthisdocumentarethedefaultsettingsfortheSentinel7000.

Compressed-air cylinders, lung demand regulators and face masks

TheDrägerPSS5000Seriesiscompatiblewithaluminumorcompositematerial

cylindersof30to60minutecapacity,andisavailablein2216psior4500psi

versions. Full descriptions and user instructions are contained in separate

instructionssuppliedwiththecylinder,facemaskorlungdemandregulator.

2.3 Intended use

The Dräger PSS 5000 Series breathing apparatus is intended for use in

applications where a high level of respiratory protection is required. When

usedwithanapprovedlungdemandregulator,facemaskandaircylinder,the

breathingapparatusprovidesawearerwithrespiratoryprotectionforworking

incontaminatedoroxygen-decientconditions.

Thecylinder,lung demandregulator,face maskand other accessoriesused

with this product must be certied Dräger components, assembled in an

approvedconguration,otherwisetheoperationofthedevicemaybeimpaired.

ContactDrägerforfurtherinformation.

2.3.1 Limitation

A limitation of the PASS automatic distress alarm is that the motion sensor

detects movement or vibration to which the wearer is subjected, and may

notactivateifthewearerismotionlessonamovingplatform(forexampleon

movingorvibratingmachinery).

2.4 Approvals

TheDrägerPSS5000SeriesiscertiedbyNIOSHandincertaincombinations

to provide protection from military grade chemical, biological, radiological,

andnuclearhazards(CBRN).The seriesisalsocertied bySEItomeet the

requirementsofNFPA1981:2007andNFPA1982:2007.Theapparatusmust

onlybeusedinconjunctionwithcompressed-aircylindersapprovedbyNIOSH.

2.5 Explanation of marking and symbols

Refertothe relevantauthority forexplanationof approvalbodysymbols and

markingontheequipment.Examplesofothermarkingoncomponentpartsof

the breathing apparatus are:

2117

3

3382

4

3380

1

3381

2

psi

BRAC-1359 – Drägerserialnumber

08/09 – Monthandyearofmanufacture

3356812orR21034 – Drägerpartnumber

SF – Standardforcecoupling

LF – Lowforcecoupling

3 Use

WARNING

Only trained and competent personnel should prepare and use

breathingapparatus.Ensurethatanyaccessories,ancillaryequipment

andotherprotectiveclothingitemsdonotinterferewiththeapparatus

anddonotcreateasafetyhazard.

WARNING

Theeffectiveworkingduration ofthe apparatusisdependent onthe

initialairsupplyavailableandthebreathingrateofthewearer.Fillair

cylinderstotheirfullratedpressurepriortouse,anddonotcommence

any operation (including supplied-air respirator (SAR) operations)

usingacylinderthatislessthan90percentfull.

CAUTION

Donotapplyexcessiveforceorusetoolstoopenorcloseacylinder

valve,anddonotdroporthrowdownthebreathingapparatus.

Refertothefollowingadditionalinformationbeforepreparingorusing

the breathing apparatus:

● Thespecialinstructions(seeSection9).

● For non-CBRN use see the separate NIOSH Approval Label

3359028forapprovedcongurations.

● For CBRN use see the separate NIOSH CBRNApproval Label

3359027 for approved congurations. For CBRN use the user

must also refer to the FPS® NFPA Lung demand Regulator and

CBRNSpecialInstructions3356259.

3.1 Preparation for use

i

i

NOTICE

Thedisplayscreenmaybettedwithathinexibleprotectivecovering.

Removethiscoveringbeforerstuse.

Ifonactivationtheunitfailstooperateoralowbatteryalarmactivates,

renewtherelevantbatteries.

1. Carryoutavisualinspectionoftheapparatus(seeSection3.5.1).

2. Installthemainbatteryandtheback-upbatteryifnecessary(seeSection

3.5.2).

3. Fittheaircylinder(seeSection3.5.3).

4. Pressthemalecouplingofthelungdemandregulatorhoseintothefemale

couplingofthemedium-pressurehoseuntil anaudibleclickisheard(do

notconnecttheregulatortothefacemaskatthisstage).

5. Presstheresetbutton(Fig3,Item1)toswitchoffthepositivepressure.

Pressandrotatethebypassbutton(Fig3,Item3)toaligntheredspotsand

thenreleasethebuttontoswitchoffthebypass.

6. InstalltheHUDintothefacemaskifnecessary(seetheHUDInstructions

forUse3356234).

7. Carryoutafullfunctionaltestoftheapparatus(seeSection3.6).

8. Align and push the lung demand regulator into face mask port until it

latchesinposition,andchecktheattachmentbygentlyattemptingtopull

thecouplingapart.

3.2 Putting on the apparatus

1. Fullyloosenthe shoulderstrapsandwaist beltandput onthebreathing

apparatus.

2. Checkthatthe shoulderpadsare nottwistedand taketheweightofthe

systemontheshouldersbypullingtheshoulderstraps.Donotfullytighten

atthisstage.

3. Closethewaistbeltbuckleandpulltheendsofthewaistbeltforwarduntil

thestrappaddingtssecurelyandcomfortablyoverthehips(Fig4).Tuck

thebeltendsbehindthewaistpad.

4. Pulltheshoulder strapsuntilthe breathingapparatusrests securelyand

comfortablyonthehips.Donotovertighten.Pullthestrapretainersdown

tosecurethestrapends(Fig5).

5. Fullyloosentheheadstrapsofthefacemaskandplacetheneckstrapover

thebackoftheneck.

6. Presstheresetbutton(Fig3,Item1)toswitchoffthepositivepressure.

7. Openthecylindervalve(counterclockwise)slowly,butfully,topressurize

system.TheSentinel7000andHUDsystemswillactivate.

WARNING

For use in a CBRN environment, use only the face mask sizes that

havebeenconrmedbyaquantitativettest(QNFT).

8. Puton the facemask andcheck for tightt (fornon-CBRN use seethe

Dräger FPS® 7000 Face Mask Instructions for Use 9021721; for CBRN

use see the FPS® NFPA Lung Demand Regulator and CBRN Special

Instructions3356259).

3.3 During use

WARNING

Fullyopenallcylindervalvesandensurethattheyremainopenduring

use.

Users should be in a safe area before the whistle or end-of-service

time warnings commence. Evacuate to a safe area immediately if

warningscommenceduringanoperation.

Observeallwarninganddisplaysignalsshownorindicatedbythesystem,and

note the following:

● Regularly check the user interface display to conrm the exact cylinder

pressureandtheremainingtimeuntilthetoend-of-servicetime(EOST)alarm

activates(seeSection8fortheEOSTactivationpressures).Bothareshown

numericallyonthenormaloperatingscreen(Fig6).Cylinderpressureisalso

shown as follows:

○ The HUD LEDs show the approximate cylinder pressure (see

Section3.3.1).

○ Thesegmentsontheuserinterfacescreenshowtheapproximatecylinder

pressure(Fig6).

● Foremergencyhelporassistance,presstheyellowbuttoninthecenterofthe

userinterfacetoactivatethemanualalarm.

● Toilluminatethedisplaybacklight,pressandreleasetheleftorrightbuttonof

theuserinterface.

○ Pressingtherightbuttonwillalsoscrollanyprogrammedpersonalidentity

information(seeSection3.7.1).

● Reacttothefollowingalarmandwarningsignalsasnecessary:

○ EOST–Theuserinterfaceemitsanaudiblealarmtone,andredandblue

LEDsashandtherstquartersectorofthesegmentdisplayashesred.

TheredLED(RinFig7)ontheHUDashes.Themechanicalwhistleon

therst-stageregulatorsounds.

○ PASS pre-alarm – If no movement is detected for approximately

25 seconds, a repeating audible alarm tone is emitted from the user

interface and the second sounder. Move the user interface within

8secondstocancelthealarm(donotattempttousethebuttonstoswitch

offthepre-alarm).

○ PASSmainalarm–Ifnomovementisdetectedafter8secondsofpre-

alarm,ahigh-levelsweepingalarmisemittedfromtheuserinterfaceand

thesecondsounder.RedandblueLEDsontheuserinterfaceandthetop

andbottomofthesecondsounderashintermittently.Theuserinterface

3088

5

1

2

3

456

LR

2

3

1

2

1

3

3383

6

psi

2189

7

R

A

G

G

B

G/Y

2580

8