(English)

2

5. Store respirator away from contaminated areas when not in use.

6. Dispose of used product in accordance with applicable regulations.

In Brazil, breathing air systems must be supplied with air which meets ANSI Z86.1-1989/CGA G-7.1, Grade D breathing air.

Use Limitations

1. This respirator does not supply oxygen when used in air-purifying mode. Do not use in atmospheres containing less than 19.5% oxygen.

2. Do not use when concentrations of contaminants are immediately dangerous to life or health, are unknown or when concentrations exceed

10 times the permissible exposure limit (PEL) in air-purifying mode when qualitatively t tested, 50 times the PEL in air-purifying mode when

quantitatively t tested, 1000 times PEL in supplied air or powered air purifying modes, or according to specic OSHA standards or applicable

government regulations, whichever is lower.

3. Do not alter, abuse or misuse this respirator.

4. Do not use with beards or other facial hair or other conditions that prevent a good seal between the face and the face seal of the respirator.

In Brazil, according to the Respiratory Protection Program of the Ministry of Labor, do not use quantitatively t tested full facepiece respirators when

concentrations of contaminants are greater than 100 times the permissible exposure limit in air-purifying mode.

Time Use Limitations

1. Cartridges and lters must be used before expiration date on packaging.

2. Particle lters must be replaced if they become damaged, soiled or if an increase in breathing resistance occurs. N-series lters should not be

used in environments containing oils. R-series lters may be limited to 8 hours of continuous or intermittent use if oil aerosols are present. In

environments containing only oil aerosols, P-series lters should be replaced after 40 hours of use or 30 days, whichever is rst.

3. Service life of gas/vapor cartridges will depend upon activity of wearer (breathing rate); specic contaminant and concentration; and

environmental conditions such as humidity, pressure, and temperature. Cartridges must be replaced in accordance with an end of service life

indicator, established change schedule or earlier if smell, taste or irritation from contaminants is detected. Please see 3M Service Life Software

at www.3M.com/sls.

4. The 6007 and 60927 mercury vapor cartridges must be discarded within 50 hours of use against mercury vapor; or according to organic

vapor, chlorine, hydrogen sulde or sulfur dioxide service life, or when odors of vapors or gases become noticeable, whichever occurs rst.

Mercury vapor has no odor.

NIOSH Cautions and Limitations

The following restrictions may apply. See NIOSH Approval Label.

A - Not for use in atmospheres containing less than 19.5 percent oxygen.

B - Not for use in atmospheres immediately dangerous to life or health.

C - Do not exceed maximum use concentrations established by regulatory standards.

D - Air-line respirators can be used only when the respirators are supplied with respirable air meeting the requirements of CGA G-7.1 Grade D or

higher quality.

E - Use only the pressure ranges and hose lengths specied in the User’s Instructions.

F - Do not use powered air-purifying respirators if airow is less than four cfm (115 lpm) for tight tting facepieces or six cfm (170 lpm) for hoods and/or

helmets.

G - If airow is cut off, switch to lter and/or cartridge or canister and immediately exit to clean air.

H - Follow established cartridge and canister change schedules or observe ESLI to ensure that cartridges and canisters are replaced before breakthrough

occurs.

J - Failure to properly use and maintain this product could result in injury or death.

L - Follow the manufacturer’s User’s Instructions for changing cartridges, canister and/or lters.

M - All approved respirators shall be selected, tted, used, and maintained in accordance with MSHA, OSHA, and other applicable regulations.

N - Never substitute, modify, add, or omit parts. Use only exact replacement parts in the conguration as specied by the manufacturer.

O - Refer to User’s Instructions, and/or maintenance manuals for information on use and maintenance of these respirators.

S - Special or critical User’s Instructions and/or specic use limitations apply. Refer to User’s Instructions before donning.

S - Special or Critical User’s Instructions

3M™ Organic Vapor Service Life Indicator Cartridges (6001i and 60921i) are equipped with a passive 3M™ End of Service Life Indicator (ESLI). The

indicator must be readily seen when wearing the respirator. If you cannot readily see the ESLI, use a mirror to observe the ESLI; rely on a co-worker

who can see the ESLI; or go to a clean area, remove the respirator and view the ESLI. Do not rely solely on the organic vapor ESLI unless your

employer has determined that it is appropriate for your workplace. See 6001i or 60921i User Instructions for more information, including Special

Instructions regarding the ESLI.

3M™ Mercury Vapor, Organic Vapor and Acid Gas Cartridges (6007 and 60927) must be discarded within 50 hours of use against mercury vapor.

3M™ Particulate Filter P95, Hydrogen Fluoride, with Nuisance Level Acid Gas Relief, 2076HF and 3M™ Particulate Filter P100, Hydrogen Fluoride,

with Nuisance Level Acid Gas Relief, 7093C are recommended for relief against nuisance levels of acid gases or organic vapors. Nuisance level refers

to concentrations not exceeding OSHA PEL or applicable government occupational exposure limits, whichever is lower. Do not use for respiratory

protection against acid gases or organic vapors, except hydrogen uoride.

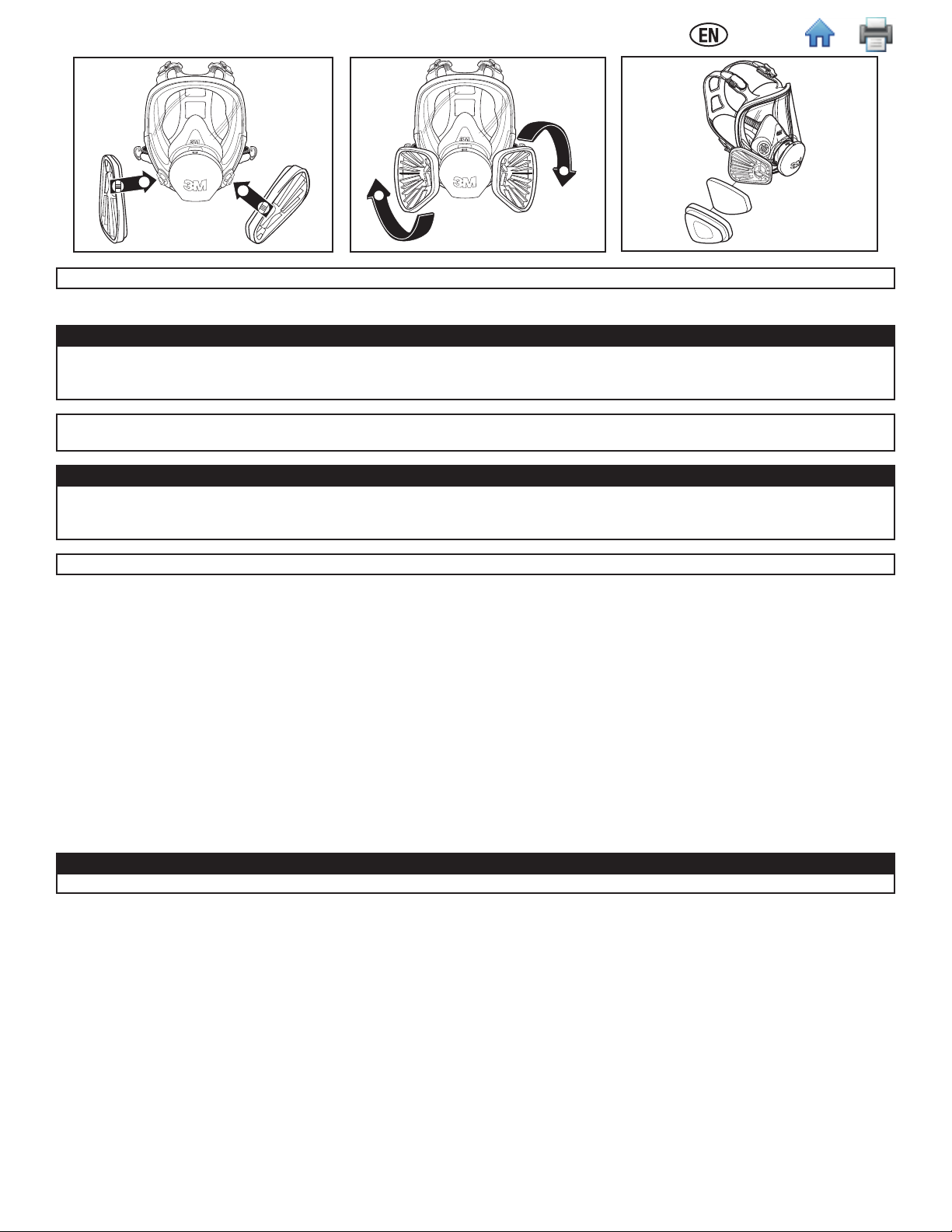

To assemble 3M™ Dual Airline Combination Breathing Tubes with 3M™ Cartridges/Filters, the facepiece inhalation valves must be removed.