6KEVA 36 G2X VOLTAGE SENSOR INSTRUCTIONS FOR INSTALLATION, USE AND MAINTENANCE

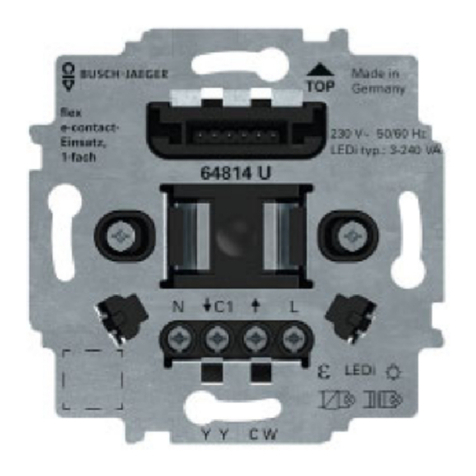

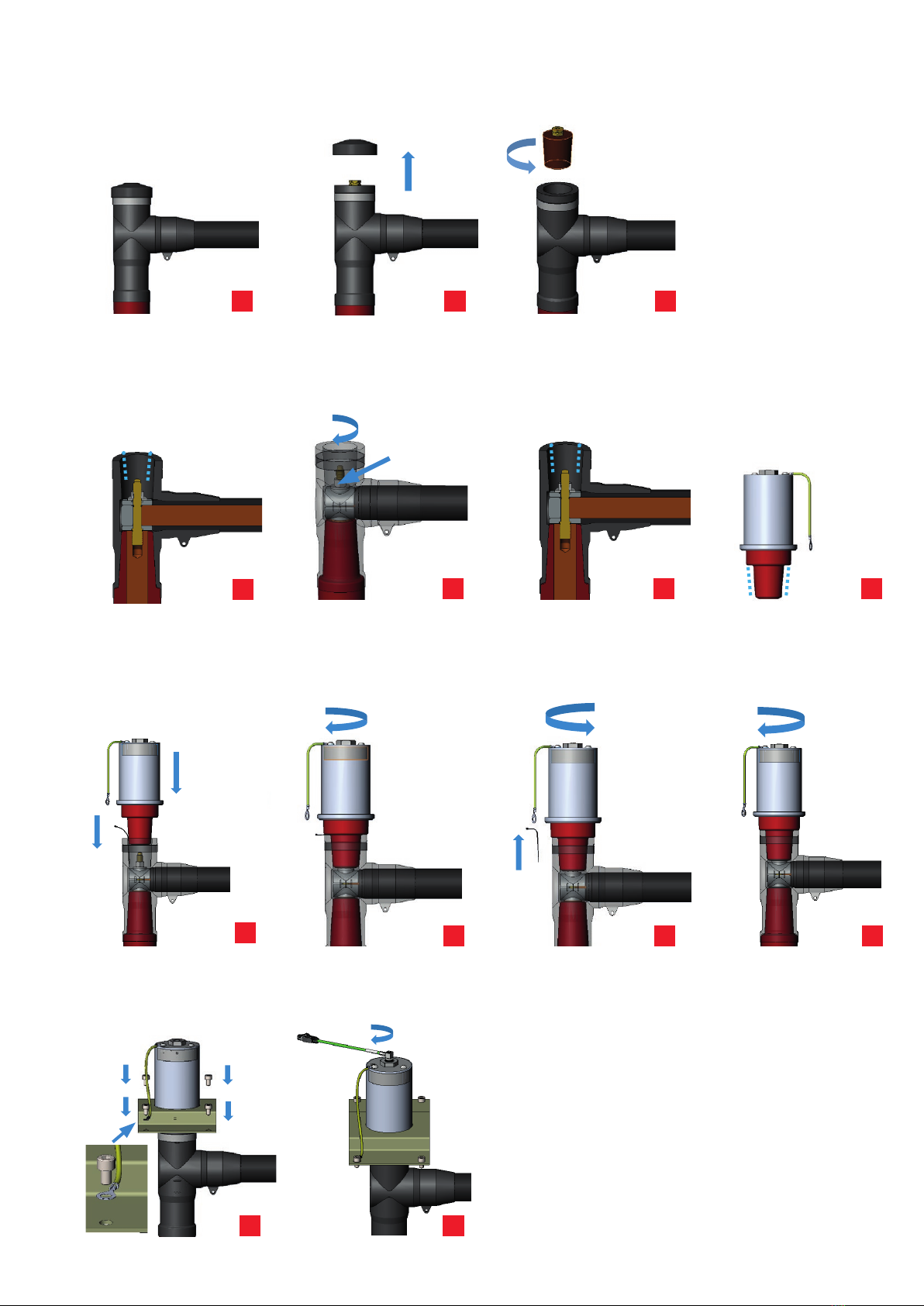

0step– originalinstallation,seepicture0

1step– removetheplugcover,seepicture1

2step– removetheinsulatingplug,seepicture2

3step– cleantheinsidesurfaceoftheadapterbypapertowel,theinsideconemustbecheckedthatthereisno

pollutionorforeignparticles(e.g.metalfilings,orsemiconductivelayeralongthecone,seepicture3)

4step– checkthetighteningoftheadapterhexnutrecommendedtighteningtorque50NmforM12nut,70Nm

forM16nutshallbeused,seepicture4

5step– spreadthe mounting grease NKT MV3 (215273435)on the inside adaptersurface(where is contact

between the sensor and the cable connector, see picture. 5, by brush or glove. Recheck that the inside

conesurfaceiswithoutpollutionorforeignparticles.

6step– Assurethatsensorconeis clean,coatsensorconewithmountinggrease(NKT MV3215273435). Usea

brushoraglovetospreadtheassemblypastealongthecone,seepicture6.

7step– Placethesensorconeontotheadapter.Pressthesensorconetogetherwithacleancabletie(toallowthe

air to escape) into the adapter, see picture 7aand turn the sensor in clockwise direction such that the

threadof theboltengagesin theinternalthread ofthesensorcone. Lightlytightenthe sensoratthe30

mm hexnut, see picture 7b. Withdraw the cable tie. Release the sensor by approximately 1 turn, see

picture7c.Screwthesensortightwithatorqueof30Nm,seepicture7d.

8step– Place the sensor base plate across the sensor, see picture 8. Insert the four screws M8 into the holes

providedinthesensorbaseplateandtightenthemwithatorqueof30Nm,assuringthatoneofthescrews

isusedtoconnectthesensorgroundingwiretotheswitchgearpanel,seepicture8.

9step– connecttheoutputcableofsensorKEVA36G2xtotheBNCconnector(checkthatthesecondarycablewith

thesameIDnumberasonthesensorlabelisused),seepicture9.

M16 – 70Nm

0step– originalinstallation,seepicture0

1step– removetheplugcover,seepicture1

2step– removetheinsulatingplug,seepicture2

3step– cleantheinsidesurfaceoftheadapterbypapertowel,theinsideconemustbecheckedthatthereisno

pollutionorforeignparticles(e.g.metalfilings,orsemiconductivelayeralongthecone,seepicture3)

4step– checkthetighteningoftheadapterhexnutrecommendedtighteningtorque50NmforM12nut,70Nm

forM16nutshallbeused,seepicture4

5step– spreadthe mounting grease NKT MV3 (215273435)on the inside adaptersurface(where is contact

between the sensor and the cable connector, see picture. 5, by brush or glove. Recheck that the inside

conesurfaceiswithoutpollutionorforeignparticles.

6step– Assurethatsensorconeis clean,coatsensorconewithmountinggrease(NKT MV3215273435). Usea

brushoraglovetospreadtheassemblypastealongthecone,seepicture6.

7step– Placethesensorconeontotheadapter.Pressthesensorconetogetherwithacleancabletie(toallowthe

air to escape) into the adapter, see picture 7aand turn the sensor in clockwise direction such that the

threadof theboltengagesin theinternalthread ofthesensorcone. Lightlytightenthe sensoratthe30

mm hexnut, see picture 7b. Withdraw the cable tie. Release the sensor by approximately 1 turn, see

picture7c.Screwthesensortightwithatorqueof30Nm,seepicture7d.

8step– Place the sensor base plate across the sensor, see picture 8. Insert the four screws M8 into the holes

providedinthesensorbaseplateandtightenthemwithatorqueof30Nm,assuringthatoneofthescrews

isusedtoconnectthesensorgroundingwiretotheswitchgearpanel,seepicture8.

9step– connecttheoutputcableofsensorKEVA36G2xtotheBNCconnector(checkthatthesecondarycablewith

thesameIDnumberasonthesensorlabelisused),seepicture9.

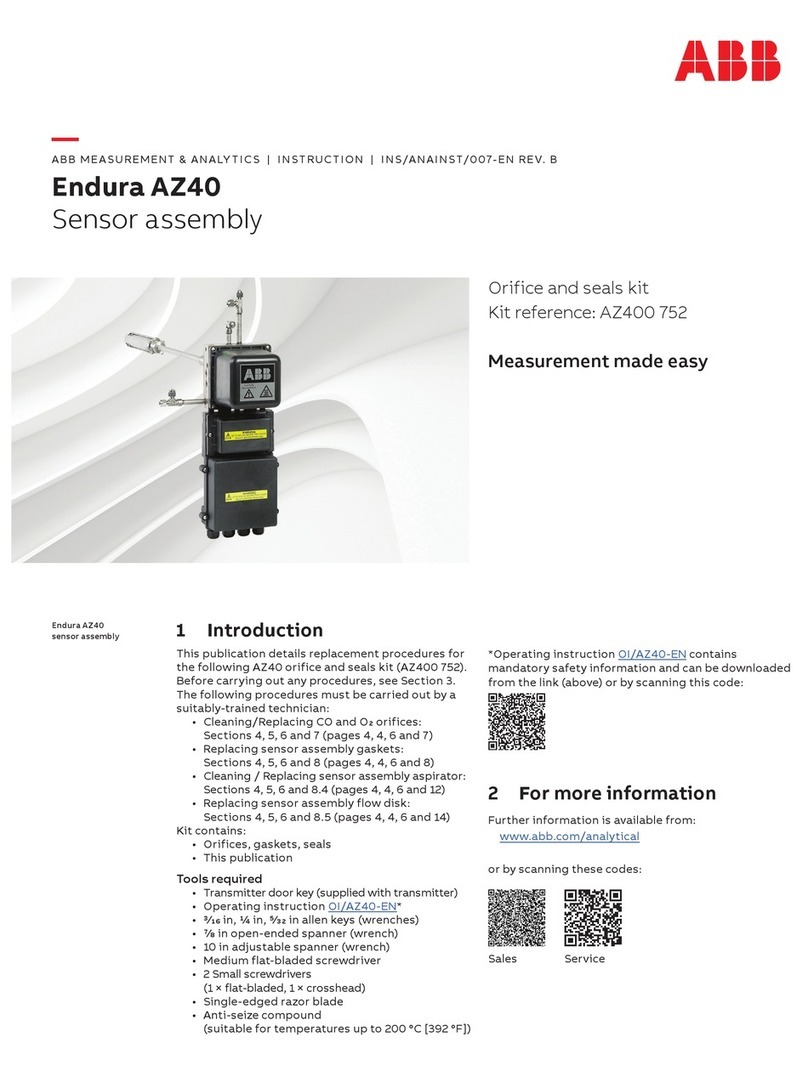

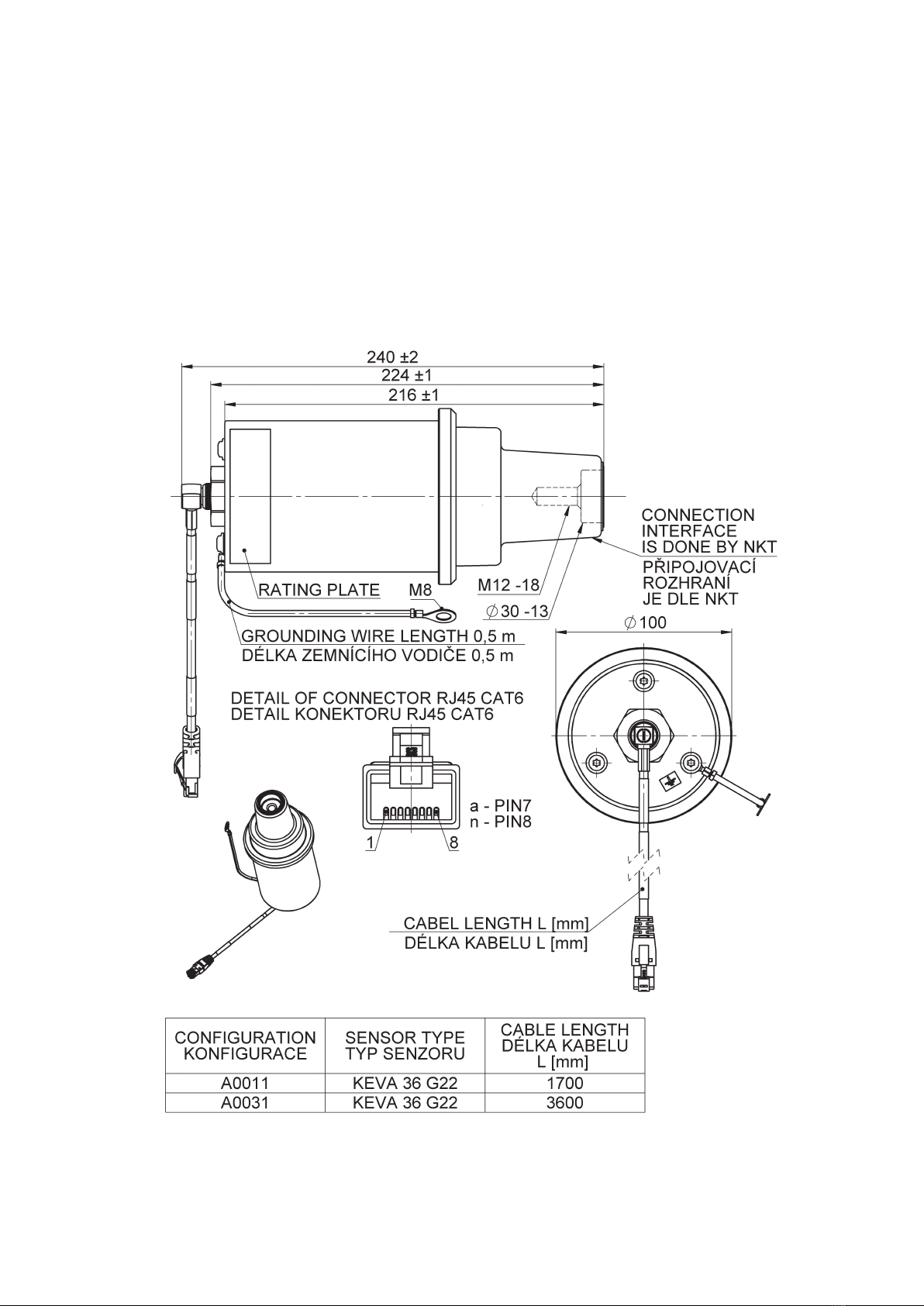

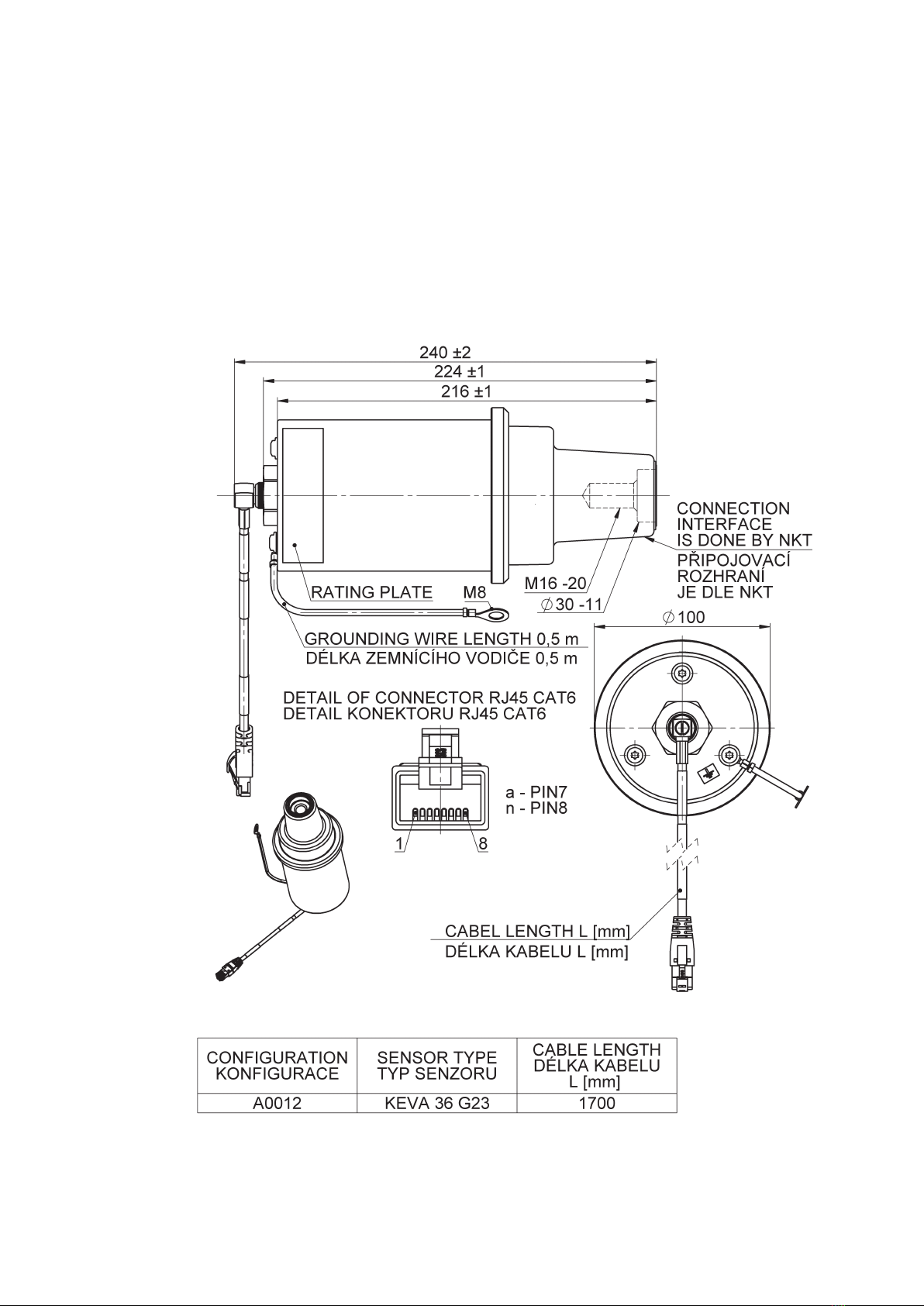

Fig.5ExampleofKEVA36G22sensorinapplication

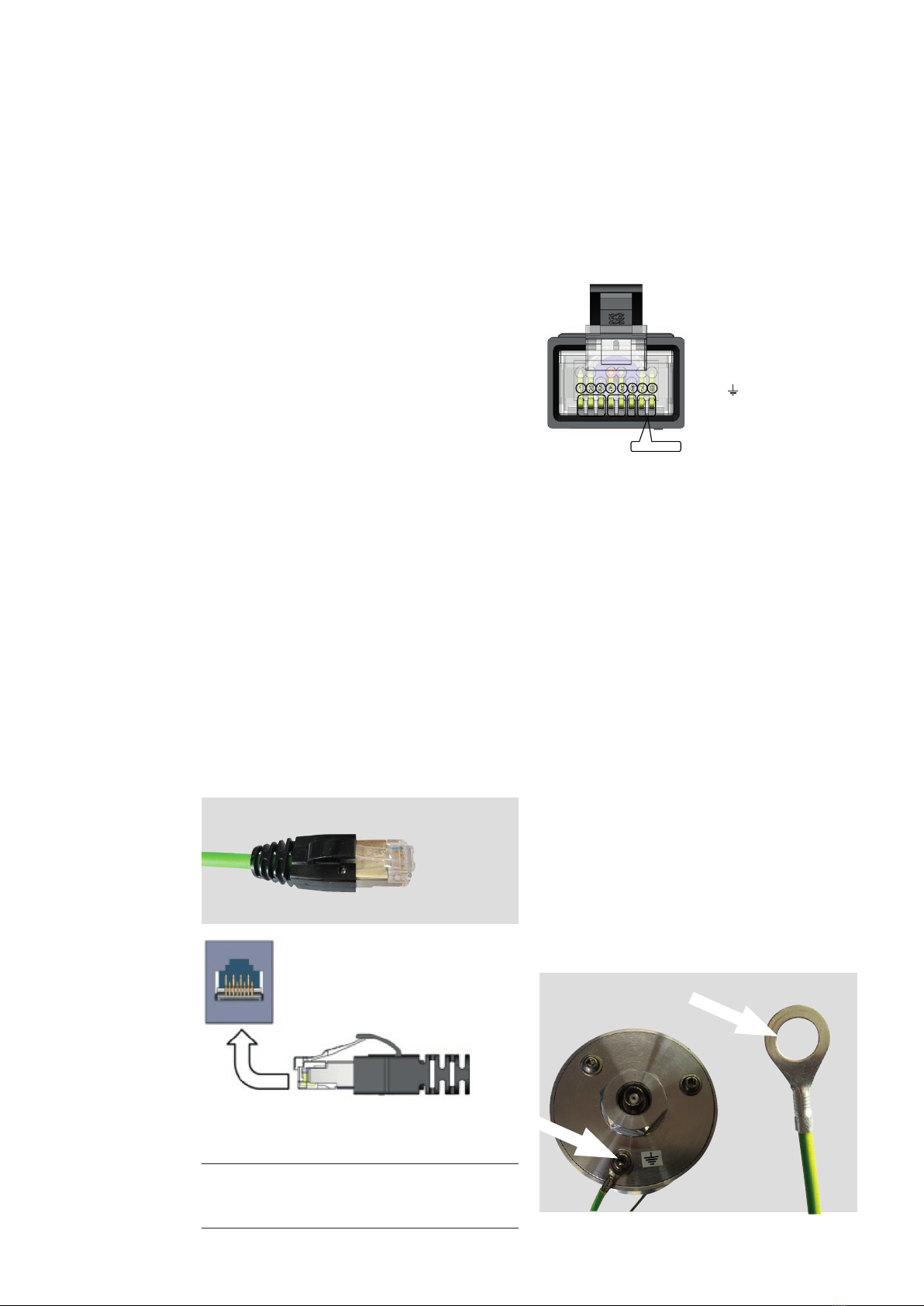

Secondarycable,secondaryconnections

The secondary cable is a special shielded cable designed to give maximum EMI shielding. The secondary cable is

inseparable part of each sensor and cannot be additionally extended, shortened, branched, modified, withdrawn or

changedduetotheguaranteeofaccuracyandperformanceofthesensor.

The cable shallbe connected directly (or via a connector adapter if needed for more information about connector

adapters and coupling adapter refer to Doc. No. 1VLC000710 Sensor Accessories) to Intelligent Electronic Device (e.g.

protectionrelay).TheelectricalshieldingofcableisconnectedtoconnectorshieldingandshallbeearthedonIEDside.The

cableshallbefixedclosetometalwallorinsertedinsideofmetalcabletrayfarfrompowercables!Theminimalbending

radius for the secondary cable is 35 mm. The cable cannot to be moved if the temperature is below 0 °C. If cable,

connectororconnectorgrommetisdamagedpleasecontactthemanufacturerforinstructions.

ConnectiontotheIED

Fig.5ExampleofKEVA36G22sensorinapplication

Secondarycable,secondaryconnections

The secondary cable is a special shielded cable designed to give maximum EMI shielding. The secondary cable is

inseparable part of each sensor and cannot be additionally extended, shortened, branched, modified, withdrawn or

changedduetotheguaranteeofaccuracyandperformanceofthesensor.

The cable shallbe connected directly (or via a connector adapter if needed for more information about connector

adapters and coupling adapter refer to Doc. No. 1VLC000710 Sensor Accessories) to Intelligent Electronic Device (e.g.

protectionrelay).TheelectricalshieldingofcableisconnectedtoconnectorshieldingandshallbeearthedonIEDside.The

cableshallbefixedclosetometalwallorinsertedinsideofmetalcabletrayfarfrompowercables!Theminimalbending

radius for the secondary cable is 35 mm. The cable cannot to be moved if the temperature is below 0 °C. If cable,

connectororconnectorgrommetisdamagedpleasecontactthemanufacturerforinstructions.

ConnectiontotheIED

Fig.5ExampleofKEVA36G22sensorinapplication

Secondarycable,secondaryconnections

The secondary cable is a special shielded cable designed to give maximum EMI shielding. The secondary cable is

inseparable part of each sensor and cannot be additionally extended, shortened, branched, modified, withdrawn or

changedduetotheguaranteeofaccuracyandperformanceofthesensor.

The cable shallbe connected directly (or via a connector adapter if needed for more information about connector

adapters and coupling adapter refer to Doc. No. 1VLC000710 Sensor Accessories) to Intelligent Electronic Device (e.g.

protectionrelay).TheelectricalshieldingofcableisconnectedtoconnectorshieldingandshallbeearthedonIEDside.The

cableshallbefixedclosetometalwallorinsertedinsideofmetalcabletrayfarfrompowercables!Theminimalbending

radius for the secondary cable is 35 mm. The cable cannot to be moved if the temperature is below 0 °C. If cable,

connectororconnectorgrommetisdamagedpleasecontactthemanufacturerforinstructions.

ConnectiontotheIED

0step– originalinstallation,seepicture0

1step– removetheplugcover,seepicture1

2step– removetheinsulatingplug,seepicture2

3step– cleantheinsidesurfaceoftheadapterbypapertowel,theinsideconemustbecheckedthatthereisno

pollutionorforeignparticles(e.g.metalfilings,orsemiconductivelayeralongthecone,seepicture3)

4step– checkthetighteningoftheadapterhexnutrecommendedtighteningtorque50NmforM12nut,70Nm

forM16nutshallbeused,seepicture4

5step– spreadthe mounting grease NKT MV3 (215273435)on the inside adaptersurface(where is contact

between the sensor and the cable connector, see picture. 5, by brush or glove. Recheck that the inside

conesurfaceiswithoutpollutionorforeignparticles.

6step– Assurethatsensorconeis clean,coatsensorconewithmountinggrease(NKT MV3215273435). Usea

brushoraglovetospreadtheassemblypastealongthecone,seepicture6.

7step– Placethesensorconeontotheadapter.Pressthesensorconetogetherwithacleancabletie(toallowthe

air to escape) into the adapter, see picture 7aand turn the sensor in clockwise direction such that the

threadof theboltengagesin theinternalthread ofthesensorcone. Lightlytightenthe sensoratthe30

mm hexnut, see picture 7b. Withdraw the cable tie. Release the sensor by approximately 1 turn, see

picture7c.Screwthesensortightwithatorqueof30Nm,seepicture7d.

8step– Place the sensor base plate across the sensor, see picture 8. Insert the four screws M8 into the holes

providedinthesensorbaseplateandtightenthemwithatorqueof30Nm,assuringthatoneofthescrews

isusedtoconnectthesensorgroundingwiretotheswitchgearpanel,seepicture8.

9step– connecttheoutputcableofsensorKEVA36G2xtotheBNCconnector(checkthatthesecondarycablewith

thesameIDnumberasonthesensorlabelisused),seepicture9.

0

4

7b

Fig.5ExampleofKEVA36G22sensorinapplication

Secondarycable,secondaryconnections

The secondary cable is a special shielded cable designed to give maximum EMI shielding. The secondary cable is

inseparable part of each sensor and cannot be additionally extended, shortened, branched, modified, withdrawn or

changedduetotheguaranteeofaccuracyandperformanceofthesensor.

The cable shallbe connected directly (or via a connector adapter if needed for more information about connector

adapters and coupling adapter refer to Doc. No. 1VLC000710 Sensor Accessories) to Intelligent Electronic Device (e.g.

protectionrelay).TheelectricalshieldingofcableisconnectedtoconnectorshieldingandshallbeearthedonIEDside.The

cableshallbefixedclosetometalwallorinsertedinsideofmetalcabletrayfarfrompowercables!Theminimalbending

radius for the secondary cable is 35 mm. The cable cannot to be moved if the temperature is below 0 °C. If cable,

connectororconnectorgrommetisdamagedpleasecontactthemanufacturerforinstructions.

ConnectiontotheIED

9

0step– originalinstallation,seepicture0

1step– removetheplugcover,seepicture1

2step– removetheinsulatingplug,seepicture2

3step– cleantheinsidesurfaceoftheadapterbypapertowel,theinsideconemustbecheckedthatthereisno

pollutionorforeignparticles(e.g.metalfilings,orsemiconductivelayeralongthecone,seepicture3)

4step– checkthetighteningoftheadapterhexnutrecommendedtighteningtorque50NmforM12nut,70Nm

forM16nutshallbeused,seepicture4

5step– spreadthe mounting grease NKT MV3 (215273435)on the inside adaptersurface(where is contact

between the sensor and the cable connector, see picture. 5, by brush or glove. Recheck that the inside

conesurfaceiswithoutpollutionorforeignparticles.

6step– Assurethatsensorconeis clean,coatsensorconewithmountinggrease(NKT MV3215273435). Usea

brushoraglovetospreadtheassemblypastealongthecone,seepicture6.

7step– Placethesensorconeontotheadapter.Pressthesensorconetogetherwithacleancabletie(toallowthe

air to escape) into the adapter, see picture 7aand turn the sensor in clockwise direction such that the

threadof theboltengagesin theinternalthread ofthesensorcone. Lightlytightenthe sensoratthe30

mm hexnut, see picture 7b. Withdraw the cable tie. Release the sensor by approximately 1 turn, see

picture7c.Screwthesensortightwithatorqueof30Nm,seepicture7d.

8step– Place the sensor base plate across the sensor, see picture 8. Insert the four screws M8 into the holes

providedinthesensorbaseplateandtightenthemwithatorqueof30Nm,assuringthatoneofthescrews

isusedtoconnectthesensorgroundingwiretotheswitchgearpanel,seepicture8.

9step– connecttheoutputcableofsensorKEVA36G2xtotheBNCconnector(checkthatthesecondarycablewith

thesameIDnumberasonthesensorlabelisused),seepicture9.

1

5

7c

0step– originalinstallation,seepicture0

1step– removetheplugcover,seepicture1

2step– removetheinsulatingplug,seepicture2

3step– cleantheinsidesurfaceoftheadapterbypapertowel,theinsideconemustbecheckedthatthereisno

pollutionorforeignparticles(e.g.metalfilings,orsemiconductivelayeralongthecone,seepicture3)

4step– checkthetighteningoftheadapterhexnutrecommendedtighteningtorque50NmforM12nut,70Nm

forM16nutshallbeused,seepicture4

5step– spreadthe mounting grease NKT MV3 (215273435)on the inside adaptersurface(where is contact

between the sensor and the cable connector, see picture. 5, by brush or glove. Recheck that the inside

conesurfaceiswithoutpollutionorforeignparticles.

6step– Assurethatsensorconeis clean,coatsensorconewithmountinggrease(NKT MV3215273435). Usea

brushoraglovetospreadtheassemblypastealongthecone,seepicture6.

7step– Placethesensorconeontotheadapter.Pressthesensorconetogetherwithacleancabletie(toallowthe

air to escape) into the adapter, see picture 7aand turn the sensor in clockwise direction such that the

threadof theboltengagesin theinternalthread ofthesensorcone. Lightlytightenthe sensoratthe30

mm hexnut, see picture 7b. Withdraw the cable tie. Release the sensor by approximately 1 turn, see

picture7c.Screwthesensortightwithatorqueof30Nm,seepicture7d.

8step– Place the sensor base plate across the sensor, see picture 8. Insert the four screws M8 into the holes

providedinthesensorbaseplateandtightenthemwithatorqueof30Nm,assuringthatoneofthescrews

isusedtoconnectthesensorgroundingwiretotheswitchgearpanel,seepicture8.

9step– connecttheoutputcableofsensorKEVA36G2xtotheBNCconnector(checkthatthesecondarycablewith

thesameIDnumberasonthesensorlabelisused),seepicture9.

2

7d

M12 – 50Nm

M16 – 70Nm

2.

unscrew

one turn

30 Nm

Fig.5ExampleofKEVA36G22sensorinapplication

Secondarycable,secondaryconnections

The secondary cable is a special shielded cable designed to give maximum EMI shielding. The secondary cable is

inseparable part of each sensor and cannot be additionally extended, shortened, branched, modified, withdrawn or

changedduetotheguaranteeofaccuracyandperformanceofthesensor.

The cable shallbe connected directly (or via a connector adapter if needed for more information about connector

adapters and coupling adapter refer to Doc. No. 1VLC000710 Sensor Accessories) to Intelligent Electronic Device (e.g.

protectionrelay).TheelectricalshieldingofcableisconnectedtoconnectorshieldingandshallbeearthedonIEDside.The

cableshallbefixedclosetometalwallorinsertedinsideofmetalcabletrayfarfrompowercables!Theminimalbending

radius for the secondary cable is 35 mm. The cable cannot to be moved if the temperature is below 0 °C. If cable,

connectororconnectorgrommetisdamagedpleasecontactthemanufacturerforinstructions.

ConnectiontotheIED

7a

2.

1.

1.

Fig.5ExampleofKEVA36G22sensorinapplication

Secondarycable,secondaryconnections

The secondary cable is a special shielded cable designed to give maximum EMI shielding. The secondary cable is

inseparable part of each sensor and cannot be additionally extended, shortened, branched, modified, withdrawn or

changedduetotheguaranteeofaccuracyandperformanceofthesensor.

The cable shallbe connected directly (or via a connector adapter if needed for more information about connector

adapters and coupling adapter refer to Doc. No. 1VLC000710 Sensor Accessories) to Intelligent Electronic Device (e.g.

protectionrelay).TheelectricalshieldingofcableisconnectedtoconnectorshieldingandshallbeearthedonIEDside.The

cableshallbefixedclosetometalwallorinsertedinsideofmetalcabletrayfarfrompowercables!Theminimalbending

radius for the secondary cable is 35 mm. The cable cannot to be moved if the temperature is below 0 °C. If cable,

connectororconnectorgrommetisdamagedpleasecontactthemanufacturerforinstructions.

ConnectiontotheIED

6

0step– originalinstallation,seepicture0

1step– removetheplugcover,seepicture1

2step– removetheinsulatingplug,seepicture2

3step– cleantheinsidesurfaceoftheadapterbypapertowel,theinsideconemustbecheckedthatthereisno

pollutionorforeignparticles(e.g.metalfilings,orsemiconductivelayeralongthecone,seepicture3)

4step– checkthetighteningoftheadapterhexnutrecommendedtighteningtorque50NmforM12nut,70Nm

forM16nutshallbeused,seepicture4

5step– spreadthe mounting grease NKT MV3 (215273435)on the inside adaptersurface(where is contact

between the sensor and the cable connector, see picture. 5, by brush or glove. Recheck that the inside

conesurfaceiswithoutpollutionorforeignparticles.

6step– Assurethatsensorconeisclean,coatsensorconewithmountinggrease( NKTMV3215273435).Usea

brushoraglovetospreadtheassemblypastealongthecone,seepicture6.

7step– Placethesensorconeontotheadapter.Pressthesensorconetogetherwithacleancabletie(toallowthe

air to escape) into the adapter, see picture 7aand turn the sensor in clockwise direction such that the

threadof theboltengages intheinternalthreadof thesensorcone. Lightlytightenthesensorat the30

mm hexnut, see picture 7b. Withdraw the cable tie. Release the sensor by approximately 1 turn, see

picture7c.Screwthesensortightwithatorqueof30Nm,seepicture7d.

8step– Place the sensor base plate across the sensor, see picture 8. Insert the four screws M8 into the holes

providedinthesensorbaseplateandtightenthemwithatorqueof30Nm,assuringthatoneofthescrews

isusedtoconnectthesensorgroundingwiretotheswitchgearpanel,seepicture8.

9step– connecttheoutputcableofsensorKEVA36G2xtotheBNCconnector(checkthatthesecondarycablewith

thesameIDnumberasonthesensorlabelisused),seepicture9.

3

Fig.5ExampleofKEVA36G22sensorinapplication

Secondarycable,secondaryconnections

The secondary cable is a special shielded cable designed to give maximum EMI shielding. The secondary cable is

inseparable part of each sensor and cannot be additionally extended, shortened, branched, modified, withdrawn or

changedduetotheguaranteeofaccuracyandperformanceofthesensor.

The cable shallbe connected directly (or via a connector adapter if needed for more information about connector

adapters and coupling adapter refer to Doc. No. 1VLC000710 Sensor Accessories) to Intelligent Electronic Device (e.g.

protectionrelay).TheelectricalshieldingofcableisconnectedtoconnectorshieldingandshallbeearthedonIEDside.The

cableshallbefixedclosetometalwallorinsertedinsideofmetalcabletrayfarfrompowercables!Theminimalbending

radius for the secondary cable is 35 mm. The cable cannot to be moved if the temperature is below 0 °C. If cable,

connectororconnectorgrommetisdamagedpleasecontactthemanufacturerforinstructions.

ConnectiontotheIED

8