Installation and maintenance guide

1ZSC000563-ACD EN, REV. A, 2019-06-25

3

Contents

1 Safety 5

1.1 Levels of safety risks ................................................................................................................................................................... 5

1.2 Hazardous working situations ..................................................................................................................................................... 6

1.3 Safety precautions....................................................................................................................................................................... 6

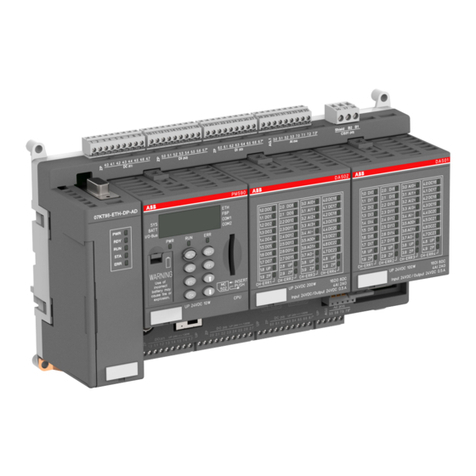

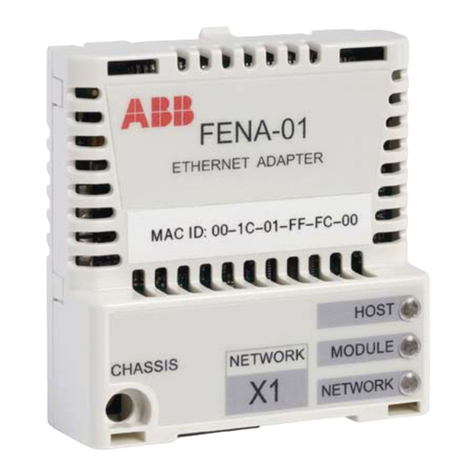

2 Product description 7

2.1 Design ......................................................................................................................................................................................... 7

2.2 Usage .......................................................................................................................................................................................... 9

2.3 Description and limitations of the tap .......................................................................................................................................... 9

3 Delivery 11

3.1 Incoming inspection..................................................................................................................................................................... 11

3.2 Transportation ............................................................................................................................................................................. 11

3.3 Storage........................................................................................................................................................................................ 11

4 Installation 13

4.1 Tools ............................................................................................................................................................................................ 13

4.2 Consumables .............................................................................................................................................................................. 13

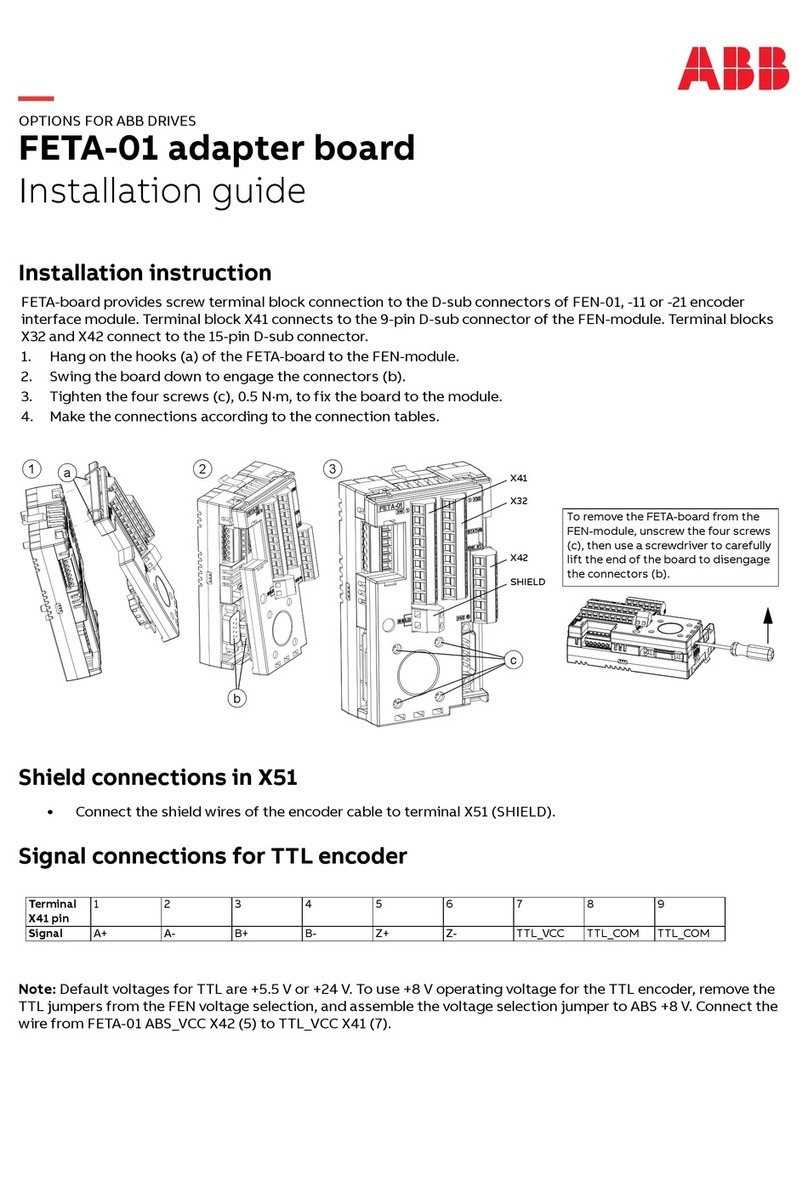

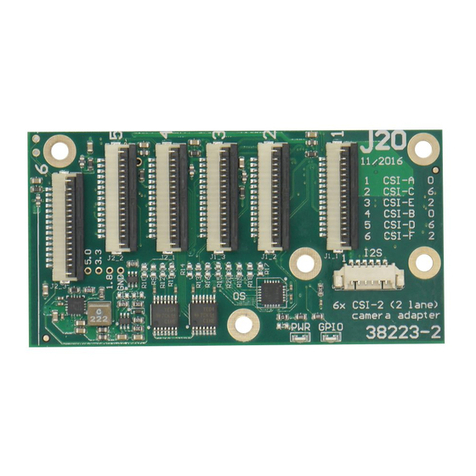

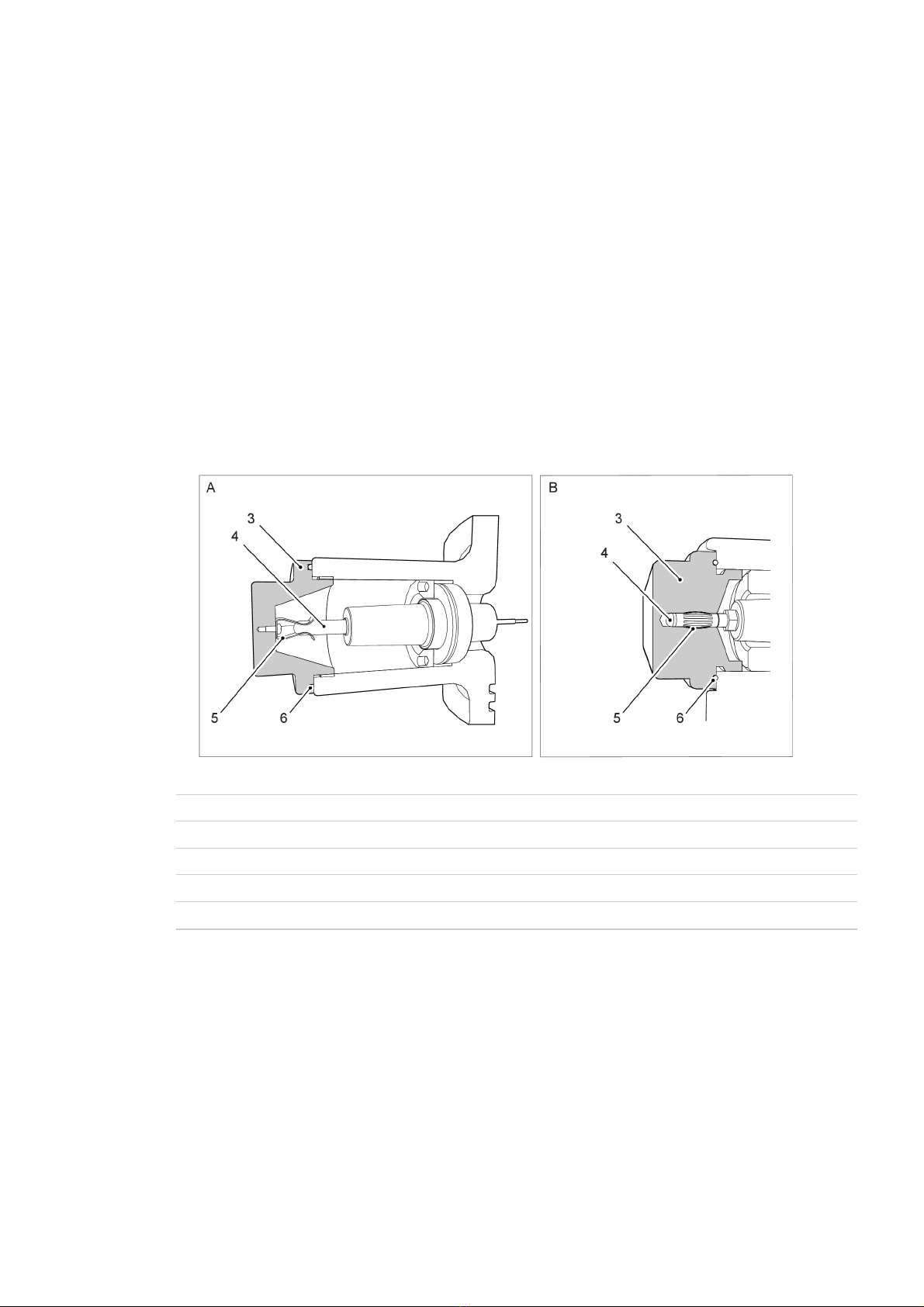

4.3 Installation of the test adapter, 1ZSC003881-AAC...................................................................................................................... 14

4.4 Installation of electrical circuits, 1ZSC003881-AAC ....................................................................................................................16

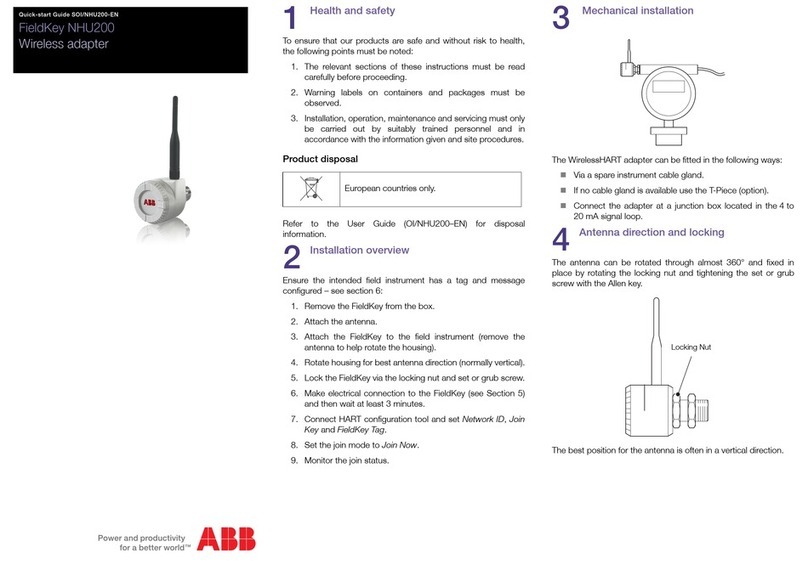

4.5 Installation of the test adapter, 2769522-C.................................................................................................................................. 19

4.6 Installation of electrical circuits, 2769522-C ................................................................................................................................ 22

5 Commissioning 25

5.1 Output error sources ................................................................................................................................................................... 25

5.2 Insulation test .............................................................................................................................................................................. 25

6 Disposal and environmental information 27

6.1 Overview ..................................................................................................................................................................................... 27

6.2 Disposal and recycling ................................................................................................................................................................ 27

7 References 29

7.1 Summary ..................................................................................................................................................................................... 29