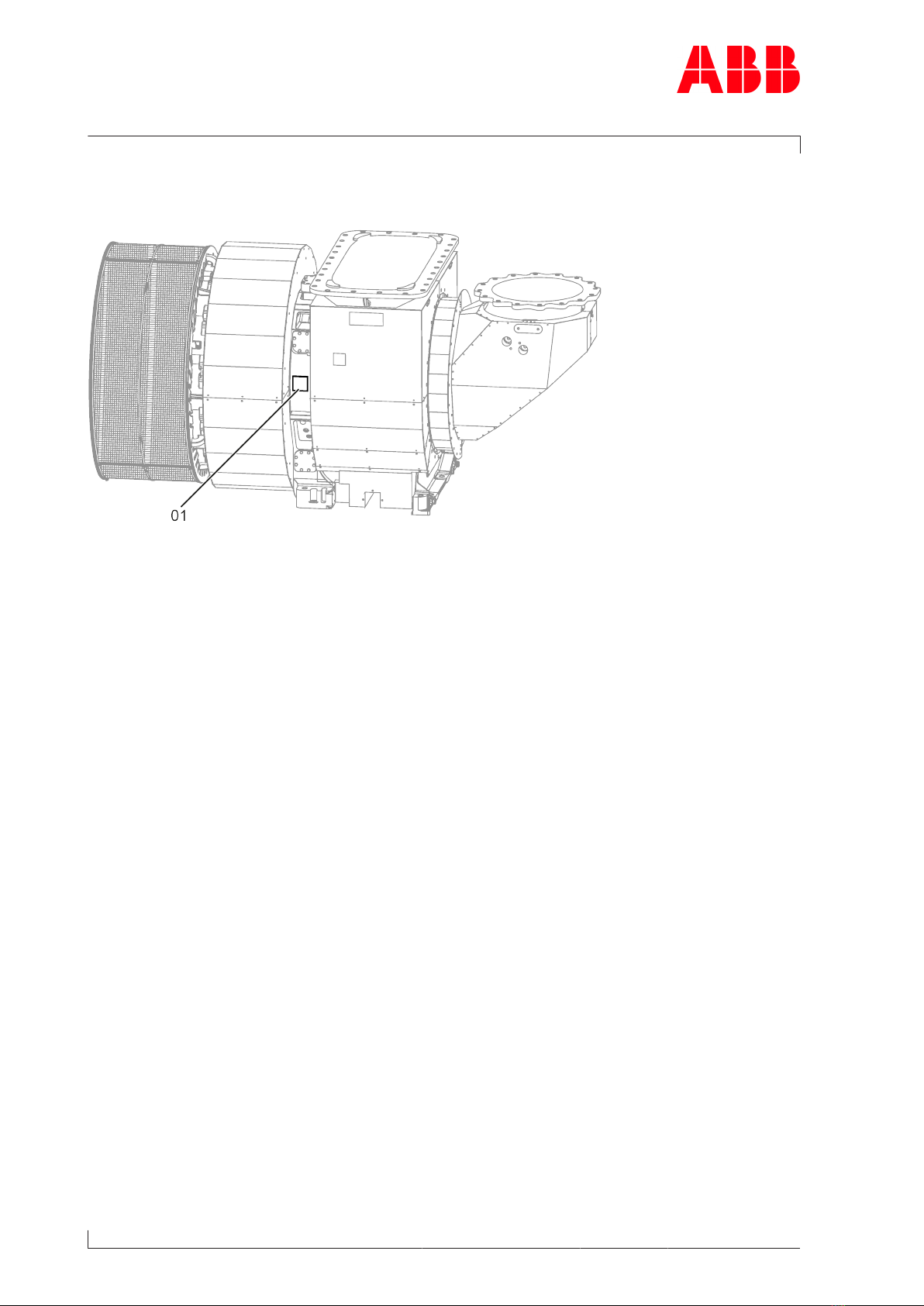

Operation Manual / A100-L

Table of contents

© Copyright 2021 ABB. All rights reserved. HZTL4034_EN Rev.T December 2021

6.5 Stopping the engine................................................................................................... 47

7 Periodic maintenance.......................................................................................... 48

7.1 Foreword to maintenance......................................................................................... 48

7.2 Cleaning the filter silencer ........................................................................................ 49

7.3 Changing the filter strip on the filter silencer casing........................................... 51

7.4 Cleaning the compressor during operation .......................................................... 53

7.5 Cleaning the turbine during operation.................................................................... 57

7.6 Draining the gas outlet casing .................................................................................. 61

8 Troubleshooting................................................................................................... 62

8.1 Malfunctions when starting...................................................................................... 62

8.2 Malfunctions during operation ................................................................................ 63

8.3 Surging of the turbocharger..................................................................................... 65

8.4 Malfunctions when stopping.................................................................................... 66

8.5 Speed measurement system.................................................................................... 67

9 Disassembly and assembly................................................................................. 68

9.1 Introduction ................................................................................................................. 68

9.2 Material required......................................................................................................... 69

9.3 Weights of assemblies............................................................................................... 70

9.4 Disassembly and assembly of the filter silencer casing ...................................... 71

9.5 Dismantling the filter silencer .................................................................................. 76

9.6 Dismantling the filter silencer with noise package ............................................. 78

9.7 Dismantling wall insert and diffuser....................................................................... 79

9.8 Axial clearance A prior to disassembly ................................................................... 83

9.9 Dismantling the insulation (≤ A175-L)..................................................................... 84

9.10 Dismantling the gas inlet casing (≤ A175-L) .......................................................... 85

9.11 Dismantling the nozzle ring (≤ A175-L) ................................................................... 86

9.12 Dismantling the gas inlet casing (≥ A180-L).......................................................... 87

9.13 Dismantling the nozzle ring (≥ A180-L)................................................................... 88

9.14 Fitting the nozzle ring (≤ A175-L) ............................................................................. 90

9.15 Fitting the gas inlet casing (≤ A175-L) ..................................................................... 91

9.16 Fitting the insulation (≤ A175-L)............................................................................... 92

9.17 Fitting the nozzle ring (≥ A180-L) ............................................................................ 93

9.18 Fitting the gas inlet casing (≥ A180-L).................................................................... 95

9.19 Axial clearance A after assembly.............................................................................. 96

9.20 Fitting the diffuser ..................................................................................................... 97

9.21 Fitting wall insert ........................................................................................................ 98

9.22 Fitting the filter silencer.......................................................................................... 100

9.23 Fitting the filter silencer with noise package ..................................................... 103

9.24 Table of tightening torques.................................................................................... 105

10 Taking a turbocharger out of operation......................................................... 107

10.1 Possible emergency repairs.................................................................................... 107

10.2 Taking defective turbochargers out of operation ............................................. 108

11 Mothballing the turbocharger........................................................................... 113