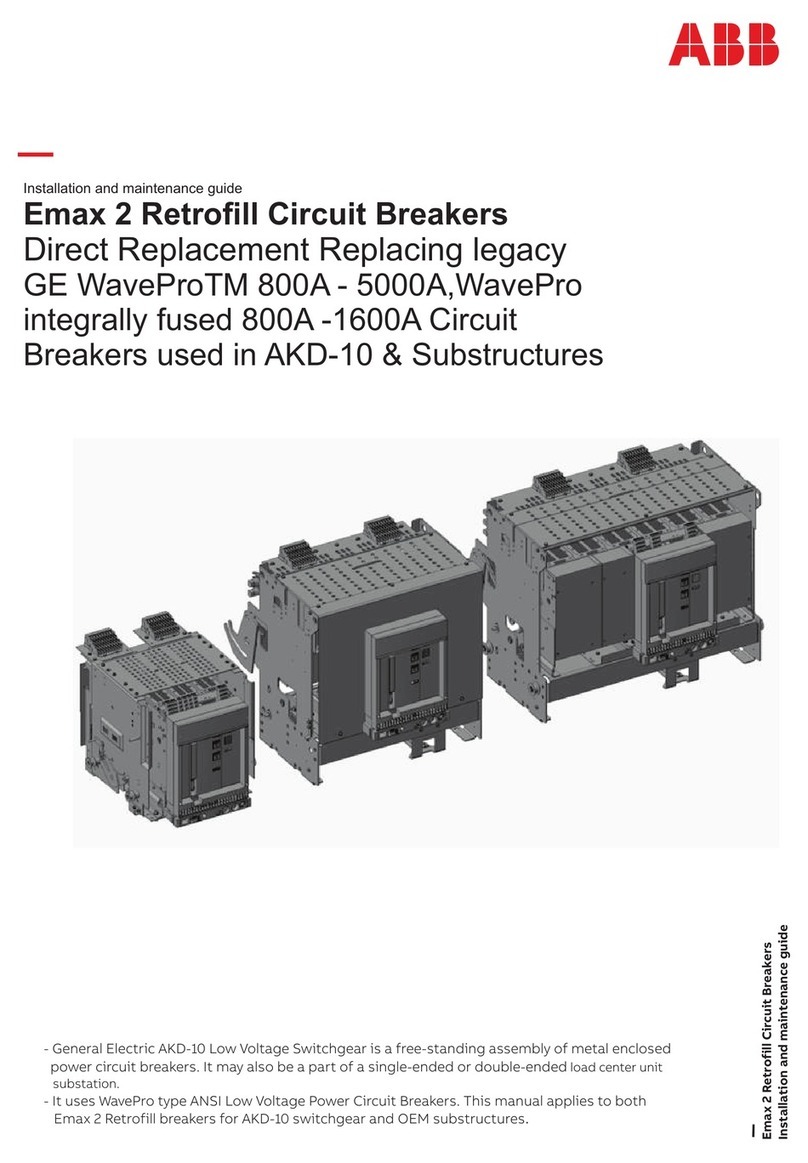

2| © 2020 Emax 2 Retrofill Circuit Breakers 600A-4000A 2TSA451011P0000 Rev-B

Contents

CONTENTS..........................................................................................2

PREFACE.............................................................................................. 3

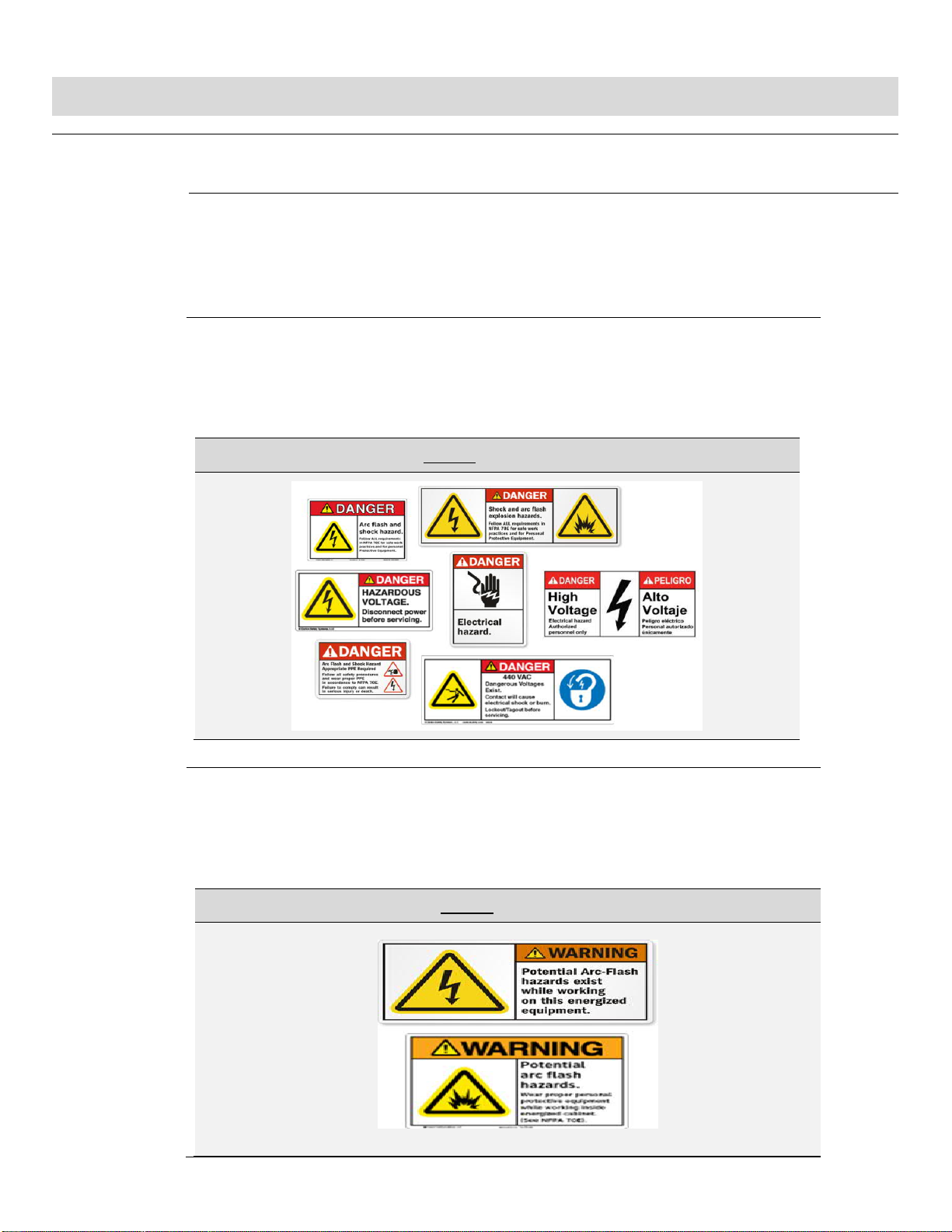

1 - Hazards................................................................................................3

2 - Warranty...............................................................................................4

3 - Trademarksand Patents.................................................................5

4- Standards............................................................................................5

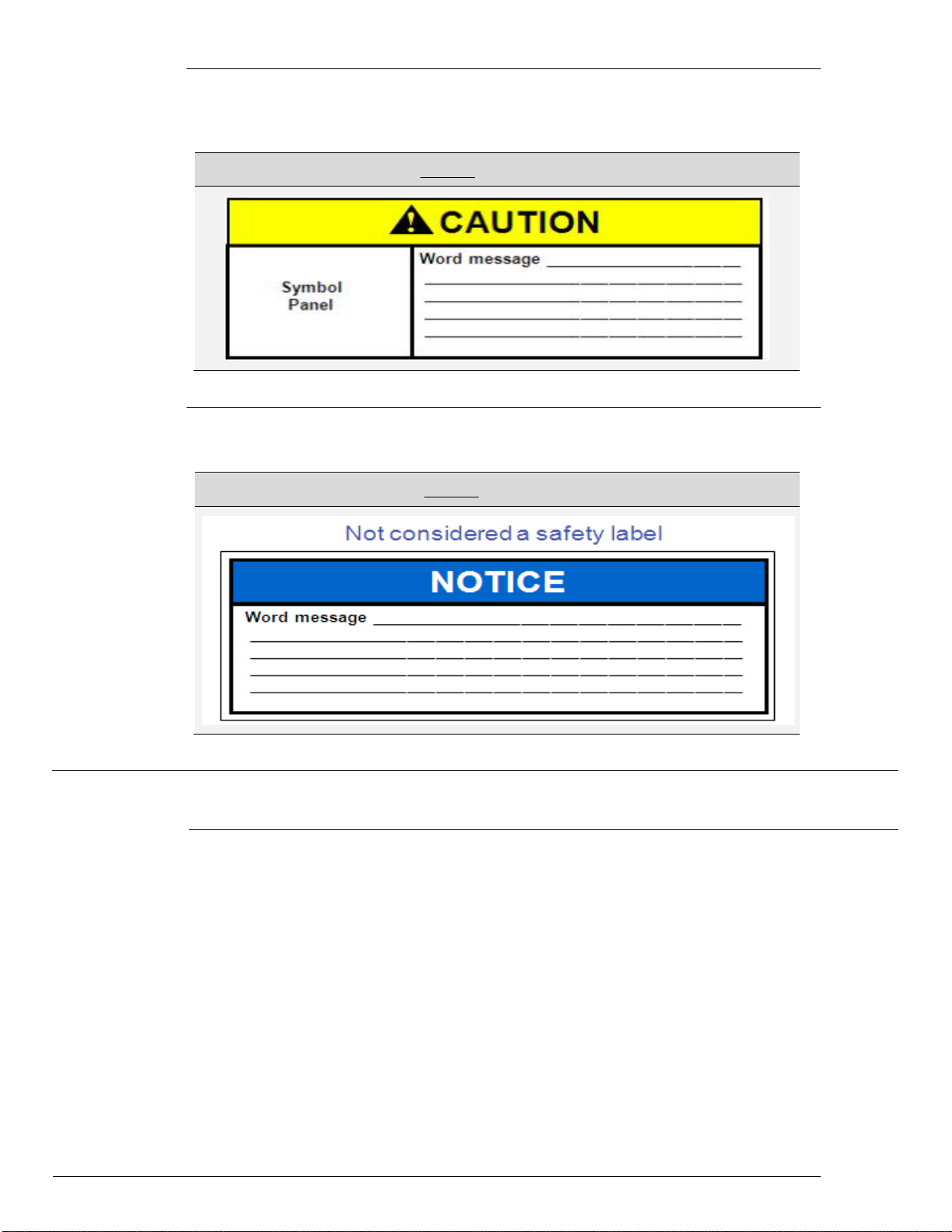

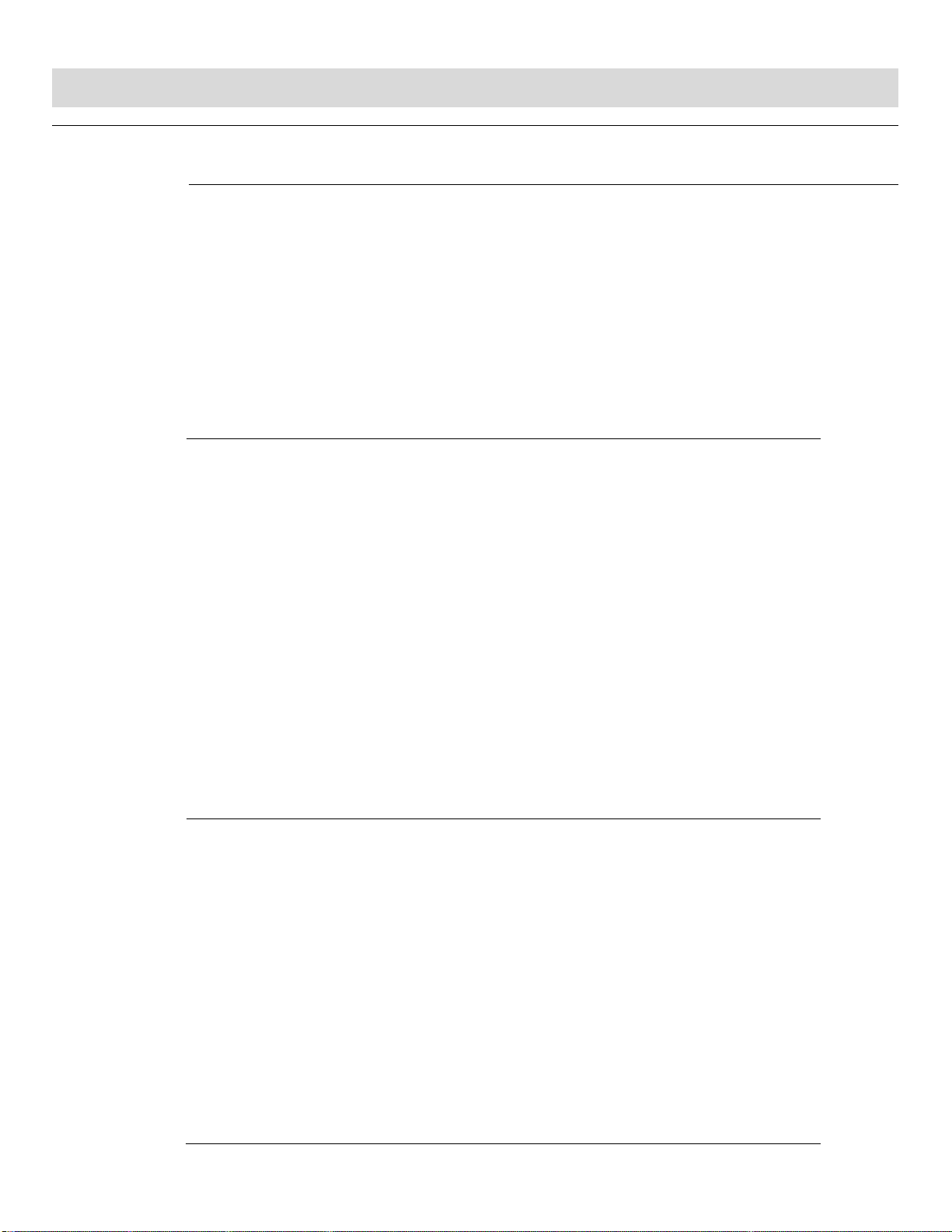

5 - Document Conventions...................................................................5

6 - Related Publications.........................................................................5

7 - Service and Support.........................................................................6

8 - Estimated Time to Complete Tasks............................................6

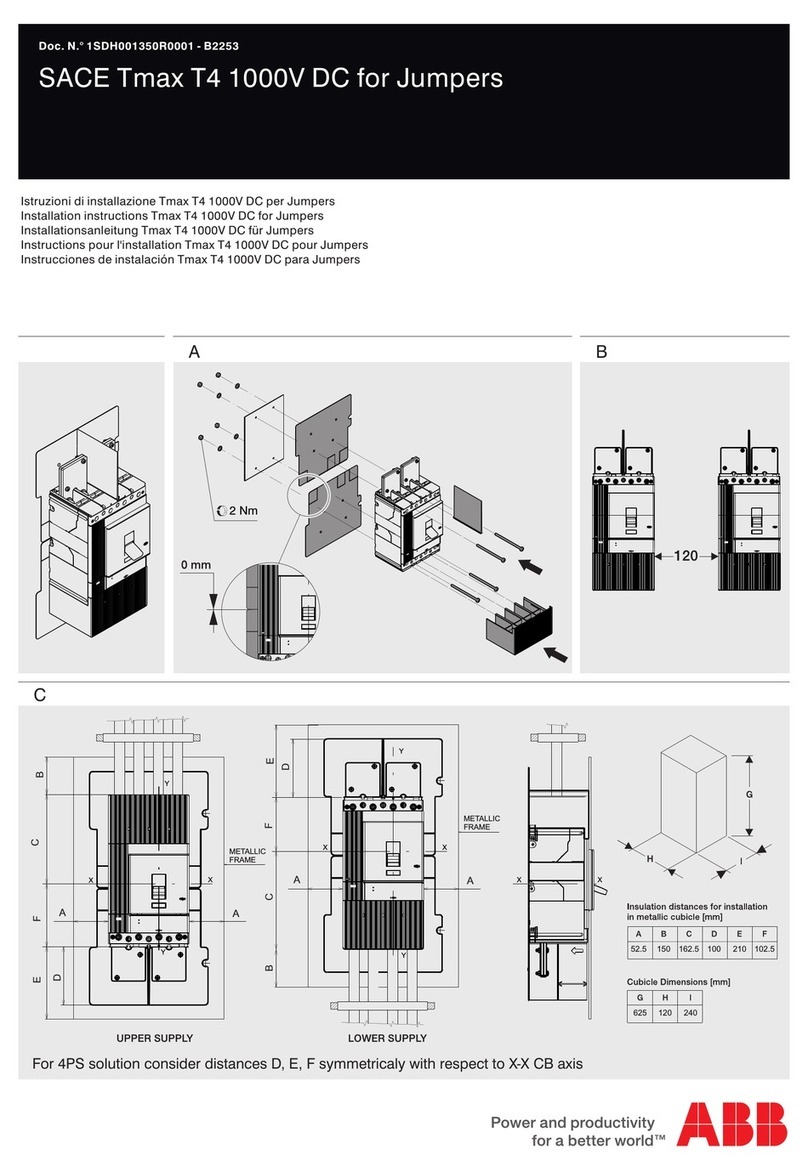

9 - ProductSpecs....................................................................................6

HISTORY ANDTYPES.........................................................................8

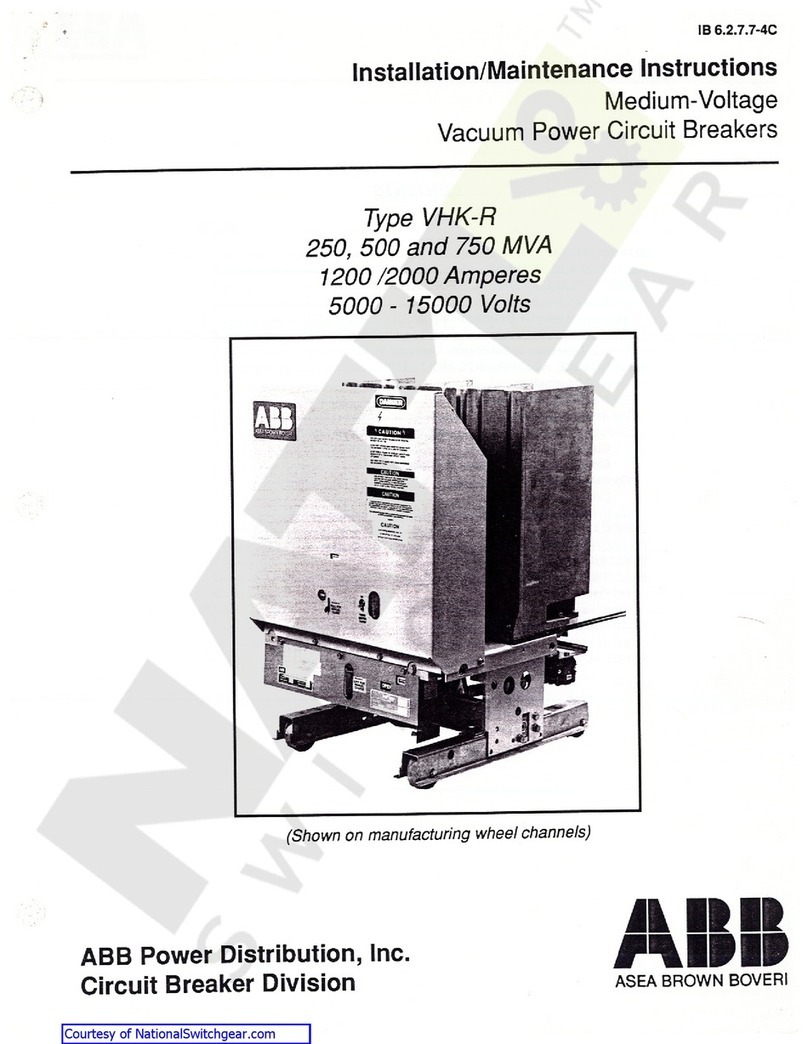

10 - History of AKD....................................................................................8

AKD - 5, RETROFILL BREAKER......................................................... 10

11 - AKD-5, BreakerModels..................................................................10

12 - AKD5 Mechanical drawings..........................................................15

MODIFY AKD-5, SWITCHGEAR COMPARTMENT............................17

13 - Turn OFF/OPEN the legacy circuit breaker.............................17

14 - Rack Out legacy circuit breaker...................................................17

15- Empty compartment legacy breakerremoved.......................17

16- Check, Clean andGrease Compartment..................................19

UNPACK RETROFILL CIRCUIT BREAKER........................................20

17 - Quality.................................................................................................21

18 - Information Label............................................................................21

19 - Product and Catalog Serial Numbers........................................21

20- Remove Circuit Breaker from Container...................................21

STORE CIRCUIT BREAKER ............................................................... 23

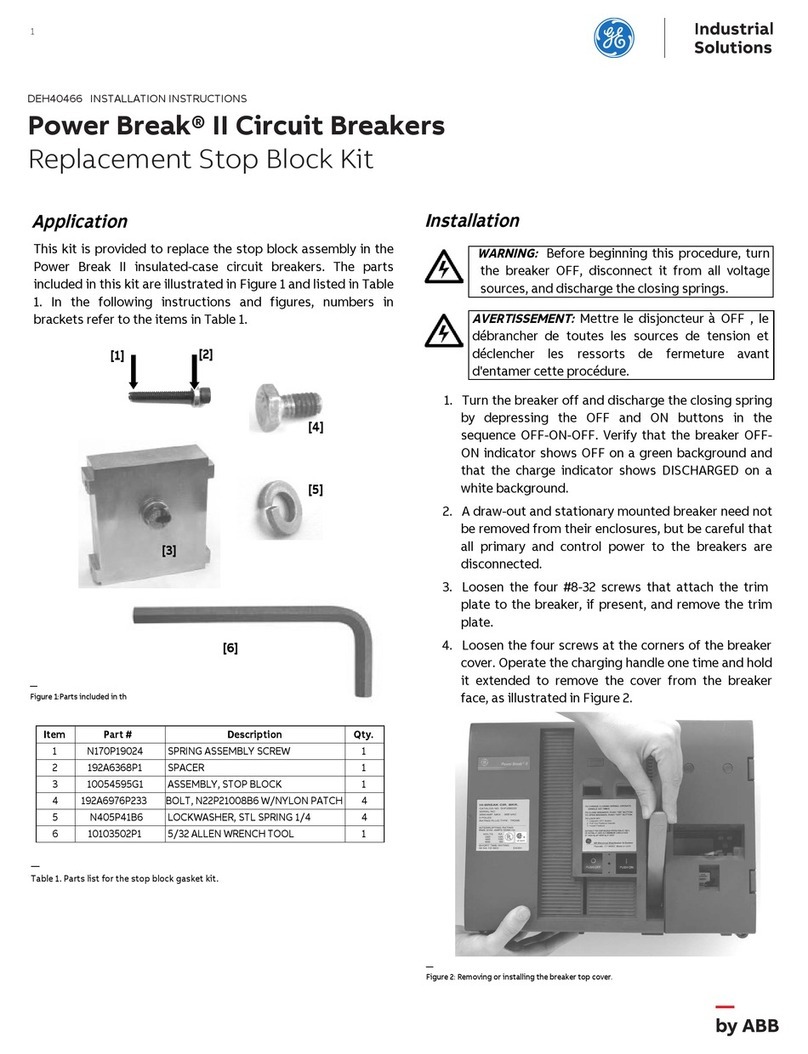

CHECK BEFORE INSTALLING..........................................................24

CLEAN AND GREASEBREAKER.......................................................25

CUSTOMIZE RETROFILLSECONDARY WIRING.............................26

INSTALL POSITION SWITCH ACTUATOR, AKT BREAKER

RETROFILL ONLY............................................................................. 27

RACKING-LOCK BRACKET INSTALLATION (AK-25/AK50/AKT50

CABINET ONLY)................................................................................28

INSTALL CASSETTE (LANDED WIRES)...........................................29

INSTALL CASSETTE RAIL LEVERLOCKOUT BRACKETS AK/AKT50

COMPT’S ONLY.................................................................................32

INSTALL AKD5 RETROFILL BREAKER.............................................33

21 - AK/AKT50 Kirkey Interlock............................................................38

22 - Secondary Disconnects, Bullets..................................................39

23 - Wiring diagram and Block info (AK25)......................................40

24- AK25 Wiring Harness, B block AK25/50................................... 45

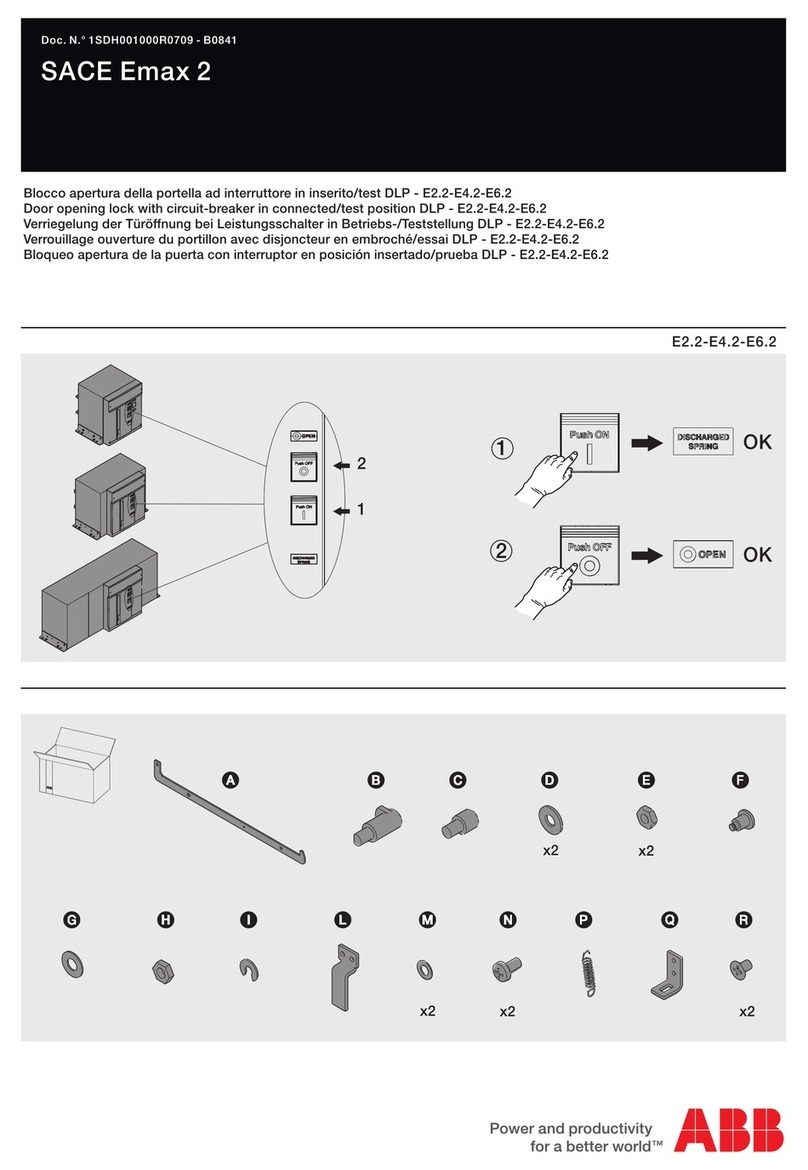

INSTALL DOOR INTERLOCK ACCESSORY.....................................46

NEWDOOR INSTALLATION............................................................. 47

INSTALL AKD-5, NEUTRAL SENSING FOR4 WIRE GROUNDFAULT

49

25- AKD-5,Neutral Disconnect Assembly.......................................49

26 - AKD-5, Neutral Disconnect Assembly, Bus Compartment.49

27- AKD-5, Neutral CT Adapter upto 5000A..................................49

28- Procedures.......................................................................................50

29 - AKD-5, Multi-Source Ground Fault.............................................51

AK 75 - 3000A, FAN CONTROL UNIT WIRING & TRIP UNIT

PROGRAMMING INSTRUCTIONS....................................................52

CONFIGURING EKIP TOUCH, HI TOUCH TRIPUNIT.....................54

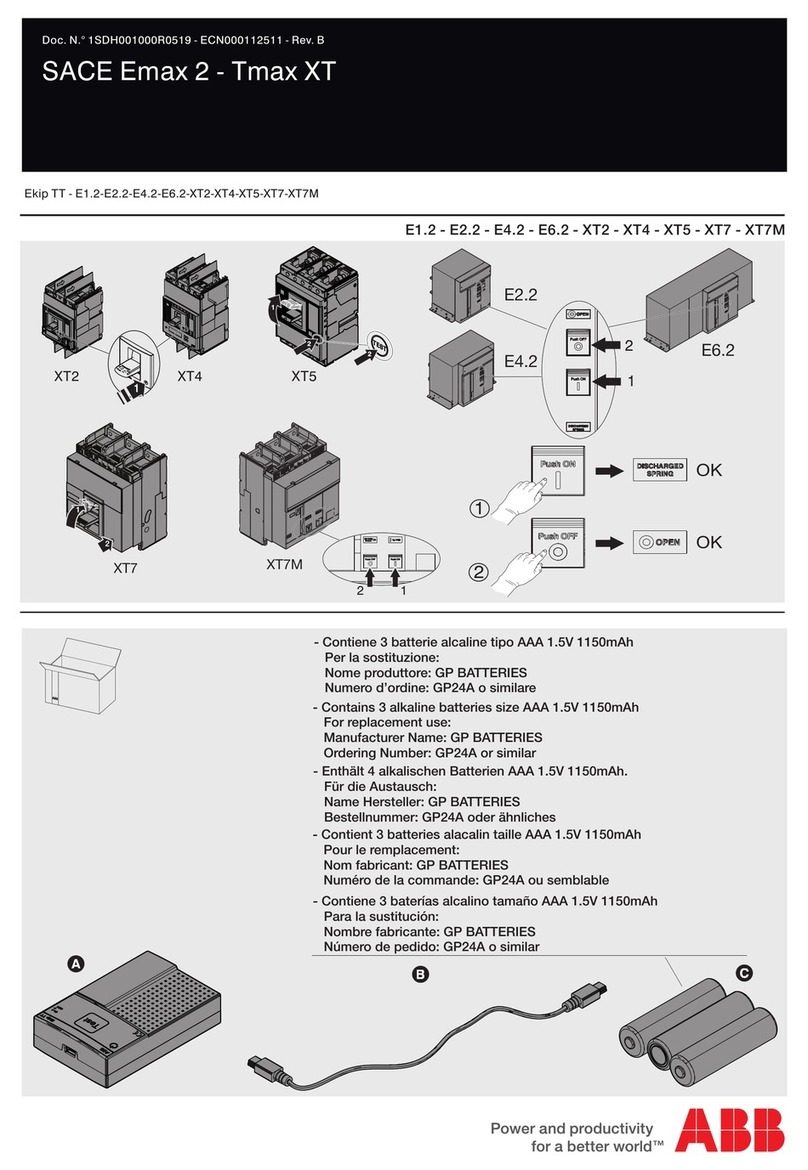

30 - Connecting Ekip Touch................................................................. 54

31- Synchronizing 2K-1 signalling modul withthe trip unit.......55

32 - Configuring threshould currents...............................................56

33- Programing 2K-1 signaling contacts output........................... 57

34- Contact readiness Auto Test.......................................................58