PREFACE............................................................................................................................................................3

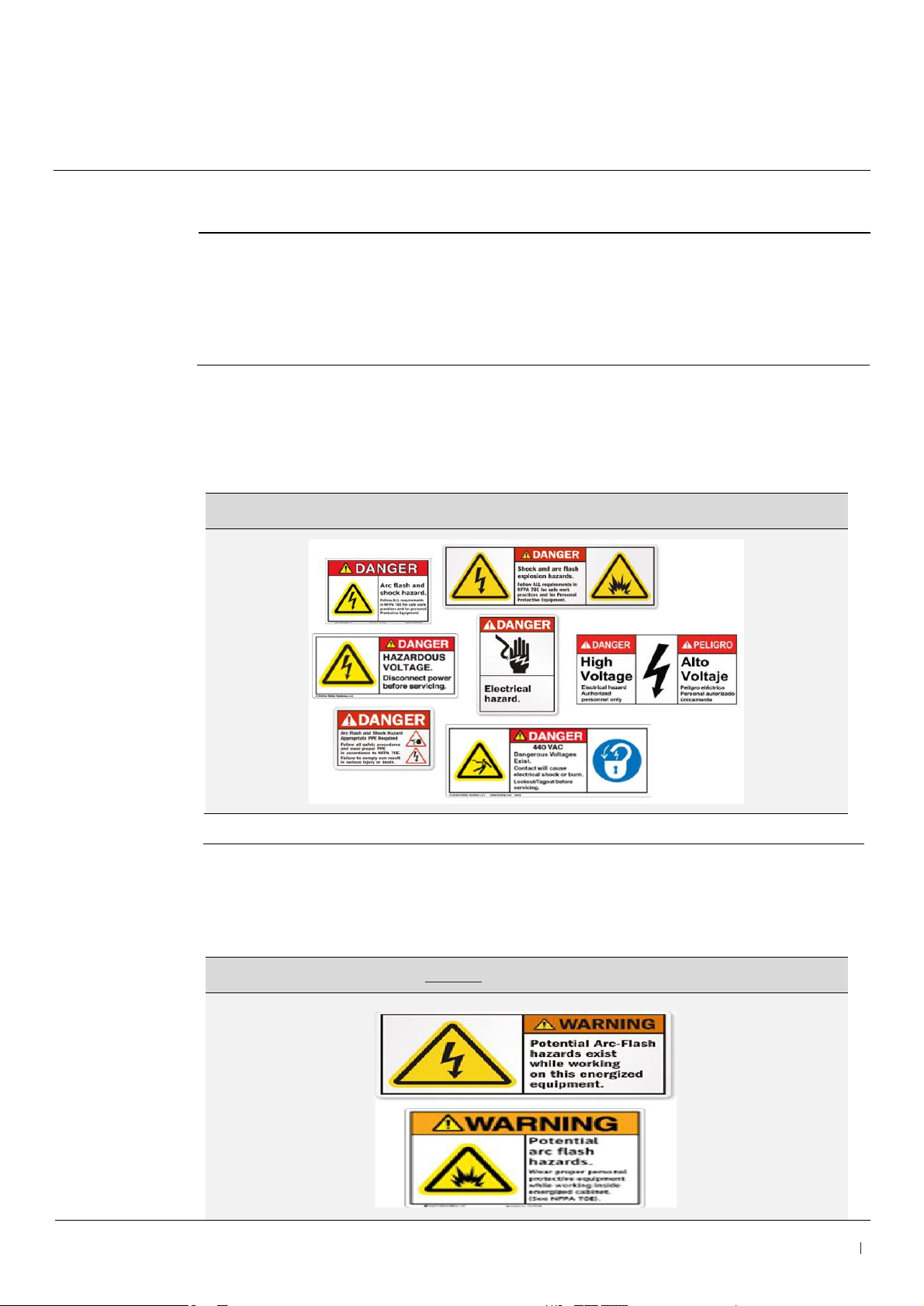

....................................................................................................................................................................31- Hazards

...................................................................................................................................................................52- Warranty

......................................................................................................................................53- Trademarks and patents

................................................................................................................................................................54- Standards

........................................................................................................................................55- Document Conventions

.............................................................................................................................................66- Related Publications

.............................................................................................................................................67- Service and Support

..................................................................................................................68- Estimated Time to Complete Tasks

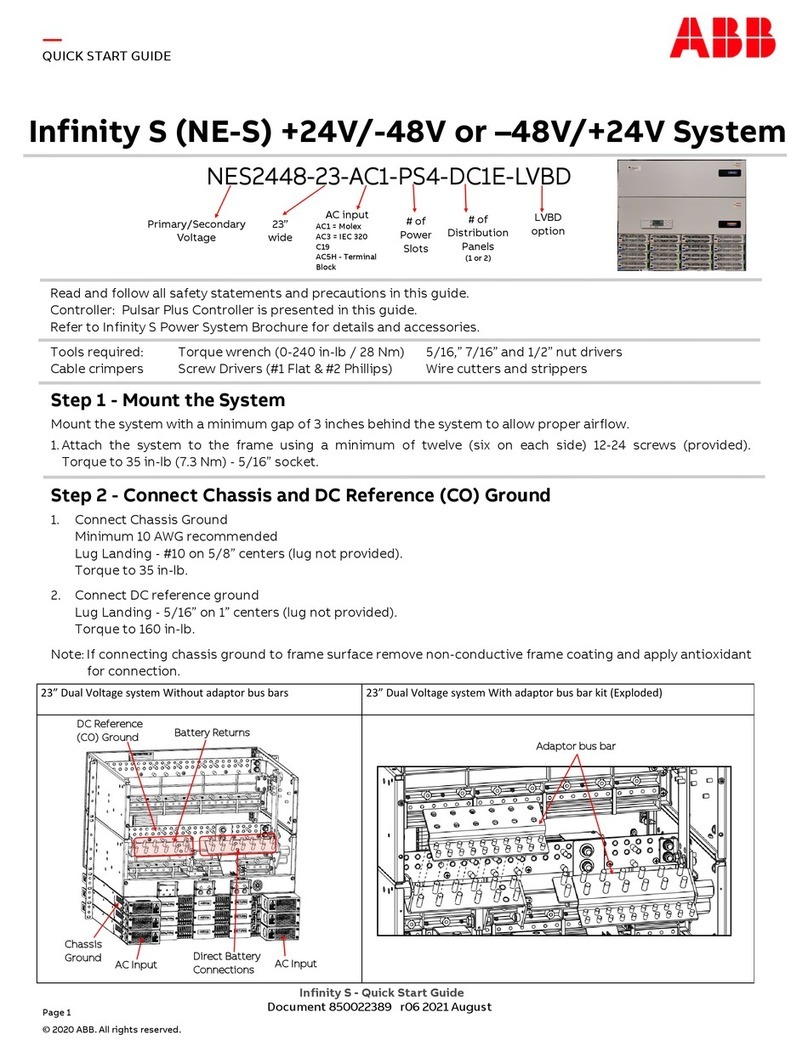

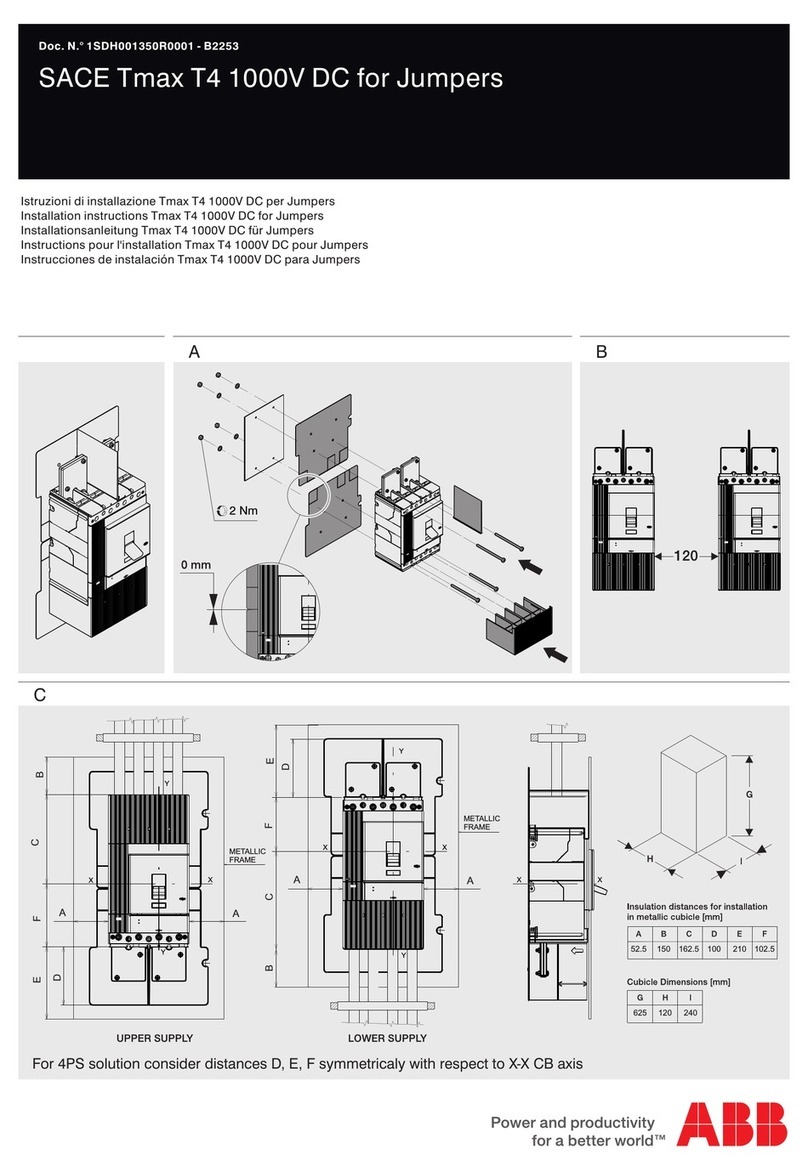

........................................................................................................................................................79- Product Specs

.......................................................................................................................................9HISTORY AND TYPES

......................................................................................................................................................910- History of AKD

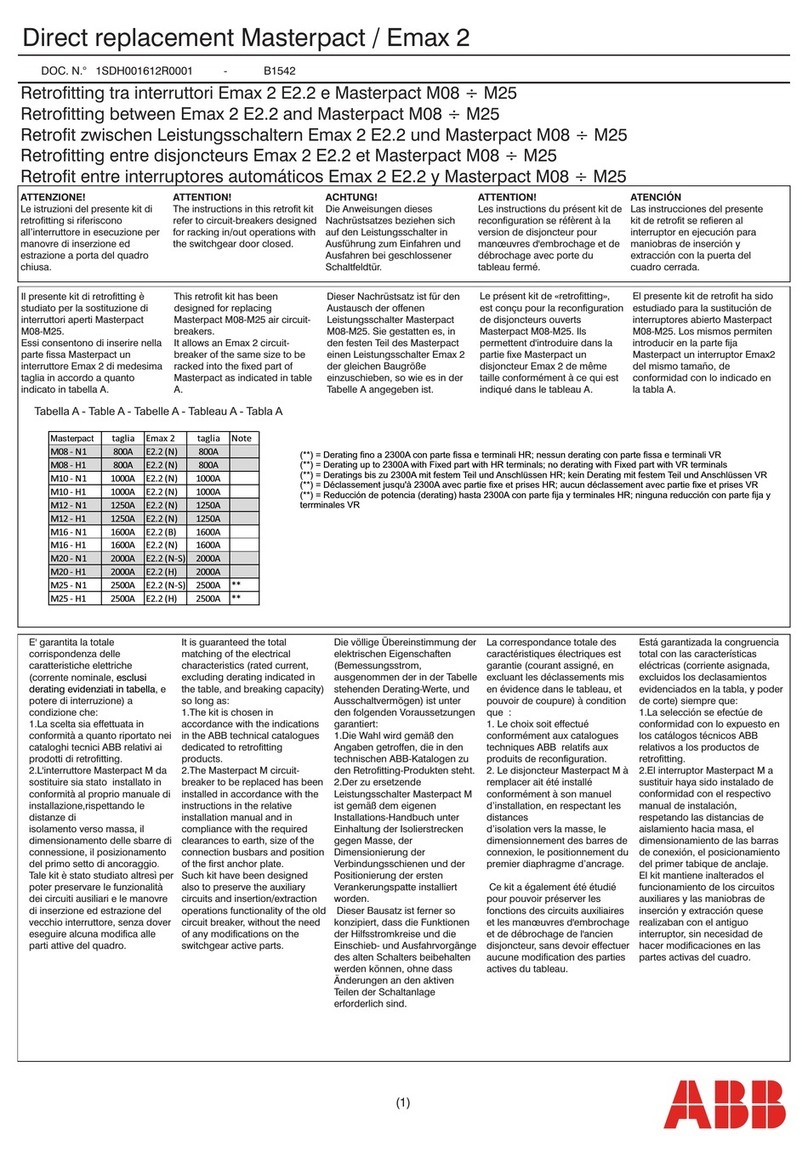

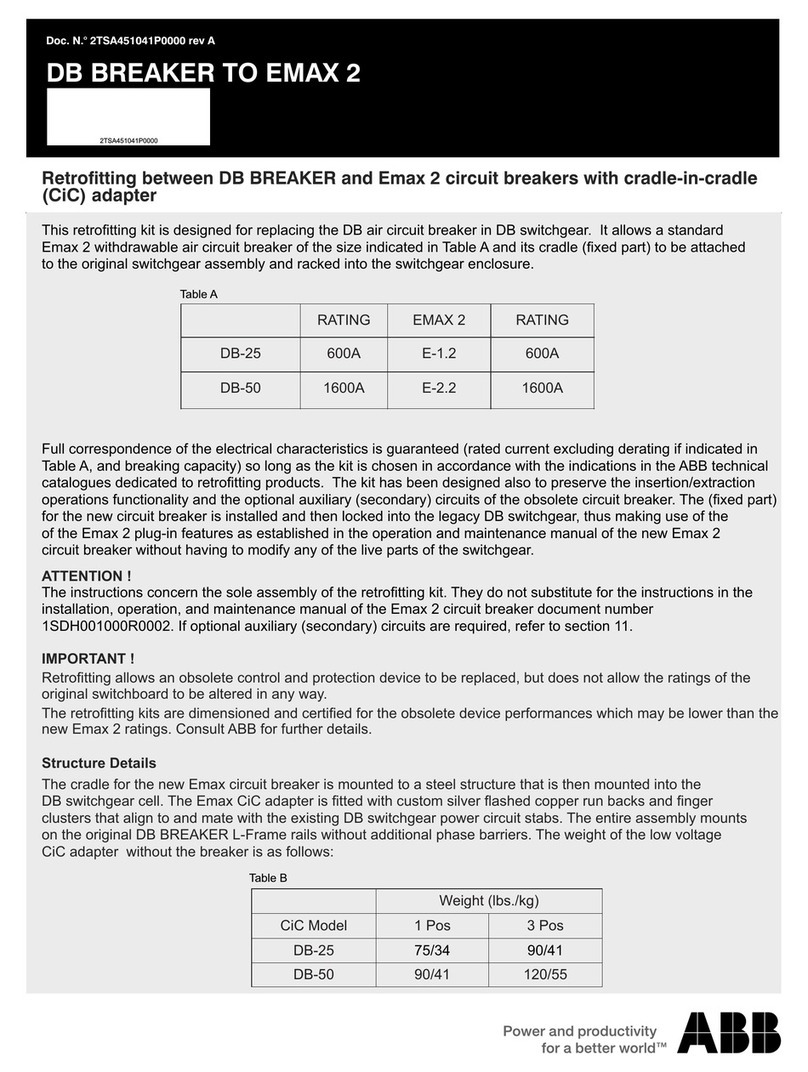

.........................................................................................................................11AKD-6, RETROFILL BREAKER

.......................................................................................................................................1111- AKD-6, Breaker Models

............................................................................................................................1212- AKD-6, Mechanical drawings

...................................................................................................................................14AKD-6 COMPARTMENT

.........................................................................................................................................................1413- Interior View

..................................................................................................16MODIFY AKD-6 , SWITCHGEAR COMPARTMENT

.........................................................................................................................1614- Cut Power to AKD-6: Switchgear

............................................................................................................................1615- Rack Out AKD-6, Legacy/Existing CB

................................................................................................1616- Check, Clean, Grease AKD-6, Compartment

....................................................................................................................................17UNPACK CIRCUIT BREAKER

...................................................................................................................................................................1817- Quality

...............................................................................................................................................1818- Information Label

.............................................................................................................1819- Product and Catalog Serial Numbers

..................................................................................................1820- Remove Circuit Breaker from Container

...............................................................................................................................19STORE CIRCUIT BREAKER

.........................................................................................................................20CHECK BEFORE INSTALLING.

.......................................................................................................................20CLEAN AND GREASE BREAKER

........................................................................................................................................21MODIFY RETROFILL

......................................................................................................22PREPARE SWITCHGEAR COMPARTMENT.

......................................................................................24INSTALLING AKD-6 RETROFILL CIRCUIT BREAKER

................................................................................................................2421- Breaker Installation Overview.

..................................................................................................2522- For AKR 30/50/T50 AKD-6 Retrofill Breaker

...........................................................................................26INSTALL OR INSERT AKD-6 RETROFILL

......................................................................................29INSTALLATION OF AKD-6 AKR 75/100 Retrofill Breaker

AKD-6 - INSTALL ACCESSORIES................................................................................................................................30

.........................................................................................................3023- AKD-6, Secondary Disconnects, Bullets

.................................................................................3624- 19 pin Programmer Secondary Disconnect (Breaker)

...................................................3925- Install 19 Pin Programmer Secondary Disconnect (Compartment)

...........................................................................................................4126- AKD-6: Position Switch Actuator

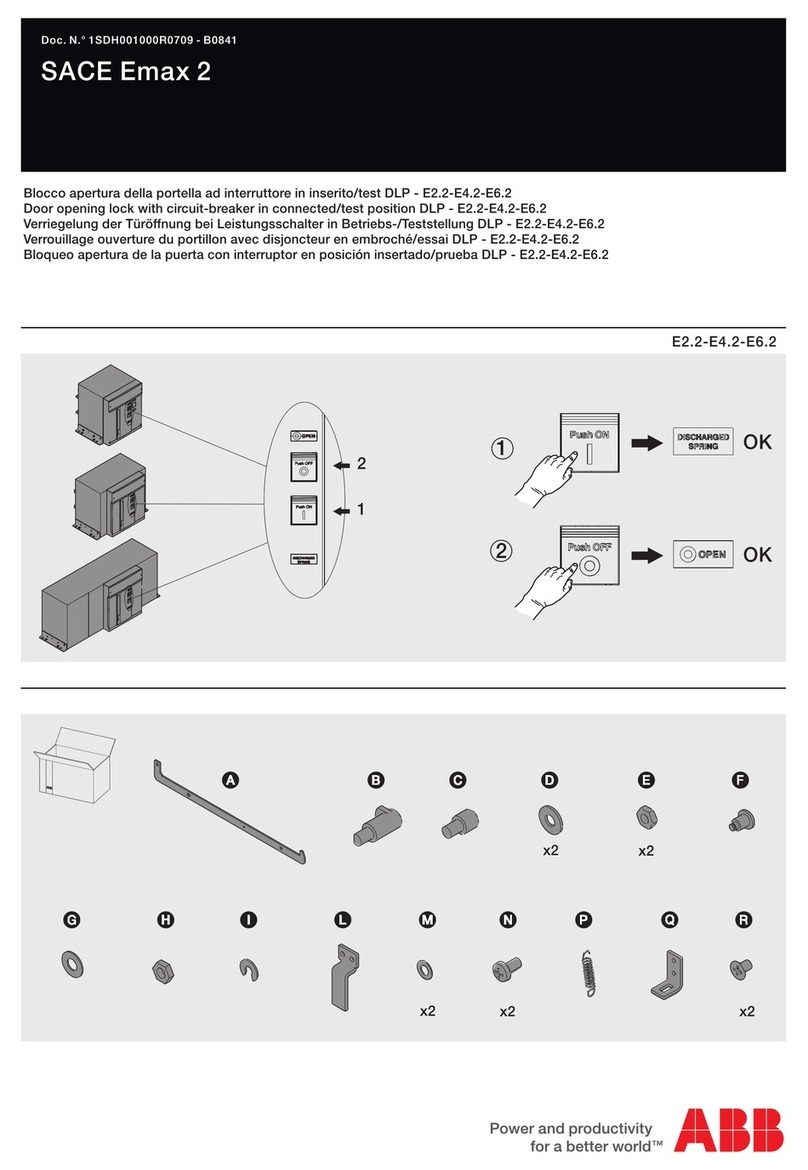

................................................................................................................................42DOOR INTERLOCK SYSTEM

.........................................................44INSTALLING NEUTRAL DISCONNECT ASSEMBLY(BREAKER SIDE)

.............45AKR 100 - 4000A , FAN CONTROL UNIT WIRING & TRIP UNIT PROGRAMMING INSTRUCTIONS

.....................................................................................47CONFIGURING EKIP TOUCH, HI TOUCH TRIP UNIT

.....................................................................................................................................4727- Connecting Ekip Touch

...........................................................................4828- Synchronizing 2K-1 signalling module with the trip unit

....................................................................................................................4929- Configuring threshould currents

................................................................................................5030- Programing 2K-1 signaling contacts output

............................................................................................................................5131- Contact readiness Auto Test

©2022 Emax 2 Retrofill Circuit Breakers 800A-4000A 2

2TSA451014P0000 Rev-B