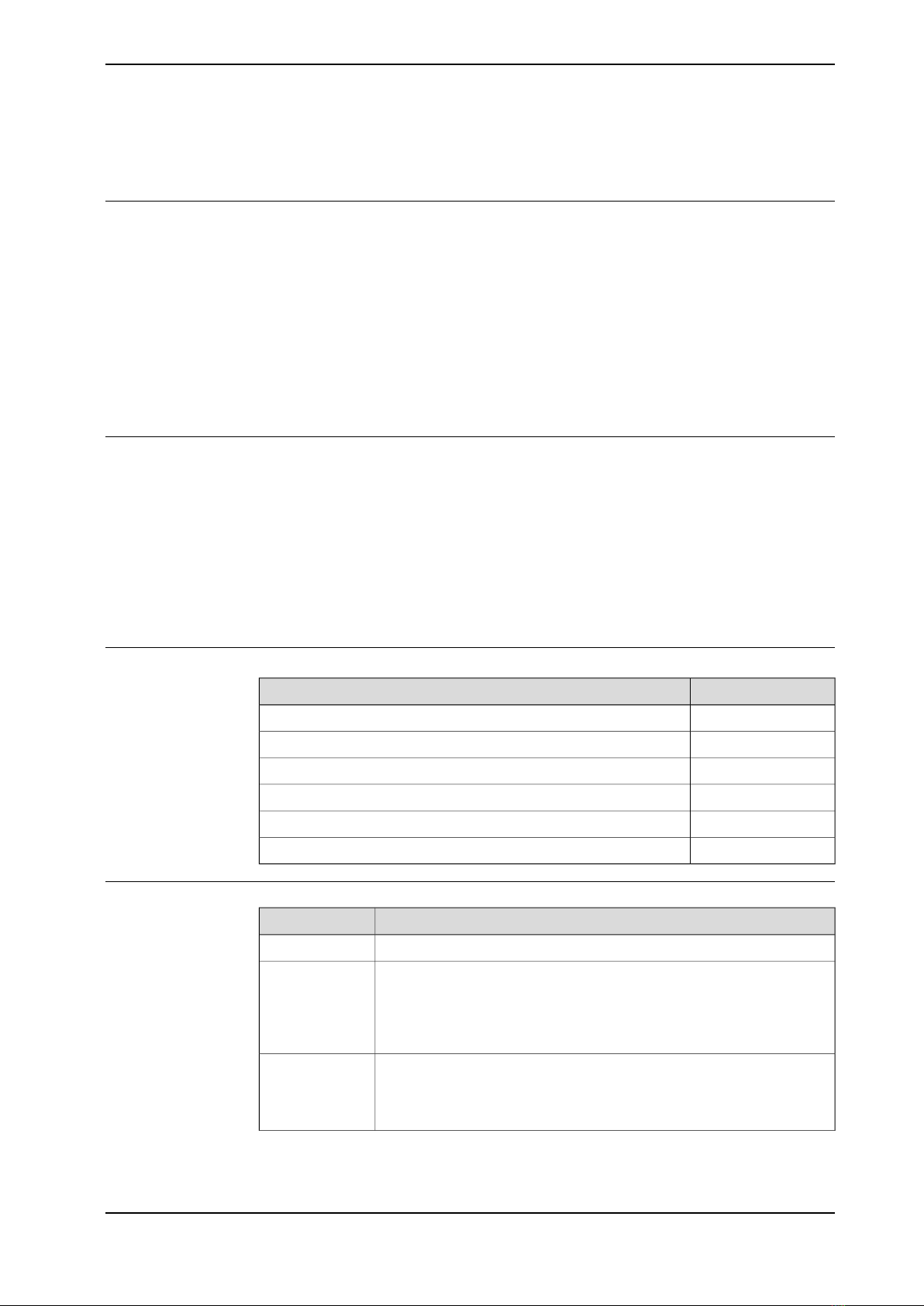

DescriptionRevision

Published in release R20D. The following updates are done in this revi-

sion:

• Minor Changes.

• Warranty section updated.

D

Published in release R21A. The following updates are done in this revi-

sion:

• Maximum TCP acceleration added.

• Connector types for CP/CS and Ethernet floor cable wiring are

added.

E

Published in release R21B. The following updates are done in this revi-

sion:

• Performance data according to ISO 9283 updated.

• Modified the air hose diameter description.

• Text regarding fastener quality is updated.

• Added a note to remind users that mechanical stop locations

cannot be adjusted.

• Removed Axis resolution.

• Added a note in manipulator protection chapter.

F

Published in release R21C. The following updates are done in this revi-

sion:

• Removed option 438-4/5/7.

• Option 3209-1 added.

G

Published in release R21D. The following updates are done in this revi-

sion:

• Supported controller OmniCore E10 is added.

H

Published in release R22A. The following updates are done in this revi-

sion:

•Added screwing depth information to attachment screws for robot

foundation.

J

Published in release R22D. The following updates are done in this revi-

sion:

• Updated power consumption data.

• Added Mains cable [3203-x].

K

Published in release R23B. The following updates are done in this revi-

sion:

• Added table for Max down force (Z stroke).

L

Published in release 23C. The following updates are done in this revision:

• The updated robot stopping distances and times are moved to

this document, and removed from the generic document, see

Robot stopping distances and times on page 45.

M

8 Product specification - IRB 910INV

3HAC068057-001 Revision: M

© Copyright 2019-2023 ABB. All rights reserved.

Overview of this manual

Continued