Table of Contents

Page

i

SECTION 1 - INTRODUCTION ....................................................................................................1-1

INTRODUCTION.............................................................................................................................1-1

INTENDED USER ...........................................................................................................................1-1

TYPE AV3/4 POSITIONER DESCRIPTION ...................................................................................1-1

TYPE AV3/4 POSITIONER APPLICATION ....................................................................................1-2

TYPE AV3/4 POSITIONER FEATURES .........................................................................................1-2

INSTRUCTION CONTENT .............................................................................................................1-3

HOW TO USE THIS INSTRUCTION BOOK ...................................................................................1-4

REFERENCE DOCUMENTS ..........................................................................................................1-5

TYPE AV3/4 POSITIONER NOMENCLATURE .............................................................................1-5

SPECIFICATIONS ..........................................................................................................................1-6

ACCESSORIES .................................................................................................................1-10

SECTION 2 - DESCRIPTION AND OPERATION........................................................................2-1

INTRODUCTION.............................................................................................................................2-1

FUNCTIONAL OPERATION ...........................................................................................................2-2

SECTION 3 - INSTALLATION .....................................................................................................3-1

INTRODUCTION.............................................................................................................................3-1

UNPACKING AND INSPECTION ...................................................................................................3-1

ENCLOSURE CLASSIFICATION ...................................................................................................3-2

MOUNTING CONSIDERATIONS ...................................................................................................3-2

MOUNTING TYPE AV3 AND AV4 POSITIONERS.........................................................................3-2

CONNECTING TUBING TO TYPE AV POSITIONER ....................................................................3-7

Filtering Supply Air ...................................................................................................................3-8

Recommended Supply Air Quality ...........................................................................................3-8

Tubing Connections .................................................................................................................3-8

WIRING TYPE AV POSITIONER....................................................................................................3-9

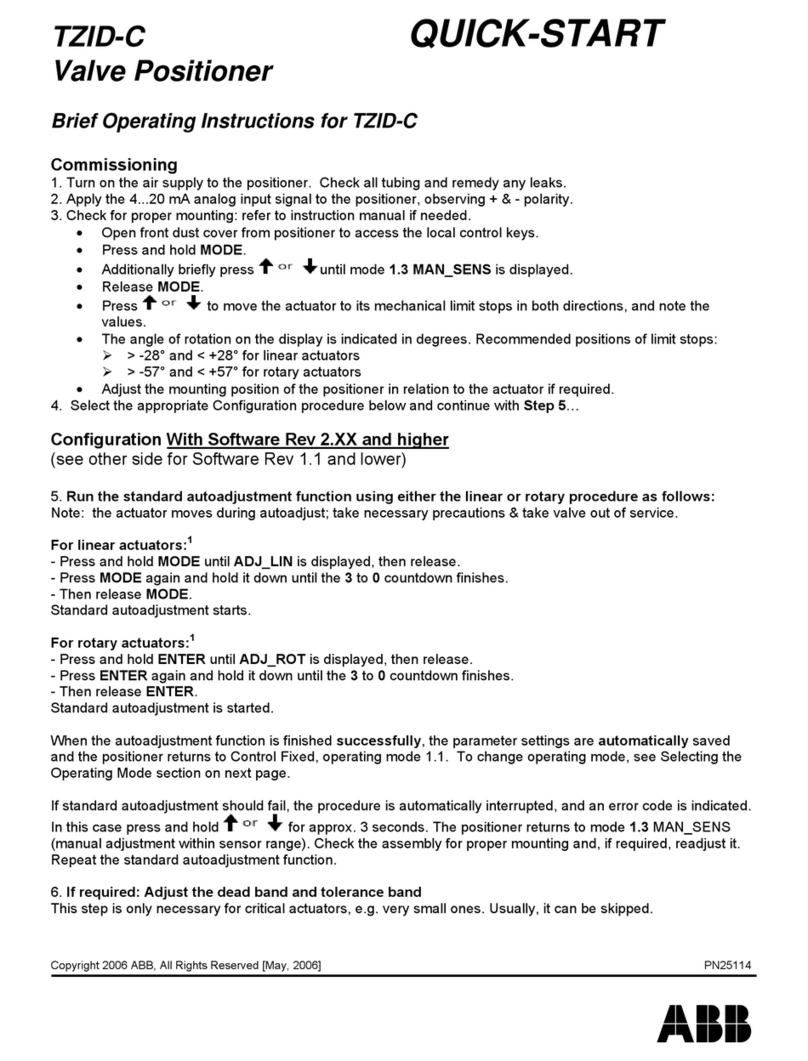

SECTION 4 - CALIBRATION.......................................................................................................4-1

INTRODUCTION.............................................................................................................................4-1

GENERAL CALIBRATION ..............................................................................................................4-1

AV3 Calibration ........................................................................................................................4-1

ZERO ADJUSTMENT (AV3).............................................................................................4-2

SPAN ADJUSTMENT (AV3).............................................................................................4-3

AV4 Calibration ........................................................................................................................4-3

ZERO ADJUSTMENT (AV4).............................................................................................4-4

SPAN ADJUSTMENT (AV4).............................................................................................4-4

SERVO MOTOR SPEED ADJUSTMENT (AV4) ..............................................................4-5

CALIBRATION FOR PARTICULAR APPLICATION (AV3 ONLY) ..................................................4-7

Zero Adjustment.......................................................................................................................4-7

Span Adjustment......................................................................................................................4-7

GAIN AND SPEED ADJUSTMENTS ..............................................................................................4-8

Gain Adjustment.......................................................................................................................4-8

Speed Adjustment....................................................................................................................4-9

ORIFICE SPEED CONTROL............................................................................................4-9

SPEED CONTROL BY PILOT VALVE STROKE ADJUSTMENT.....................................4-9

TROUBLESHOOTING CALIBRATION ADJUSTMENTS..............................................................4-11

Servo Assembly Adjustments (Type AV3 Positioner) ............................................................4-11

Servo Adjustments (Type AV4 Positioner).............................................................................4-14