888-490-9552 www.acousa.com

OLEOPATOR P OPERATION MANUAL

ACO ENVIRONMENT

4

1.2 QUALIFICATIONS OF PERSONNEL

All work performed on the separator

equipment is to be carried out by trained

personnel.

1.3 PERSONAL SAFETY EQUIPMENT

Personal safety equipment is necessary

for a variety of works on the separator.

1.4 RESPONSIBILITY OF OWNER

The owner is responsible for complying

with the following points:

Only operate the separator according

to regulations and in proper

conditions.

Ensure that protection devices are

functional.

Adhere to a scheduled maintenance

program and immediately repair

faults. Only repair faults yourself if

the measures are described in these

operating instructions. Contact ACO

for all other measures.

Inspect data plate on the separator for

completeness and legibility.

Adequate personal safety equipment

must be available and used.

Provide complete and legible

operating instructions at the

separator’s site of installation and

training based on this.

Only employ qualied and authorized

personnel.

HEALTH & SAFETY

Safety instructions are intended to

prevent injury to personnel or damage to

equipment and must be read before any

maintenance is performed.

The separated oils and any vapors are

ammable and/or combustible. Care

must be taken whenever the system is

opened.

All safety instruction labels must be

replaced if they become detached or

illegible.

Gas concentrations MUST be tested

before entering the separator;

breathing apparatus is recommended

for all personnel entering separator.

Safety lines, harnesses and radios/

whistles are advised if entering

separator.

Smoking and naked lights are

strictly forbidden anywhere in area

surrounding the system.

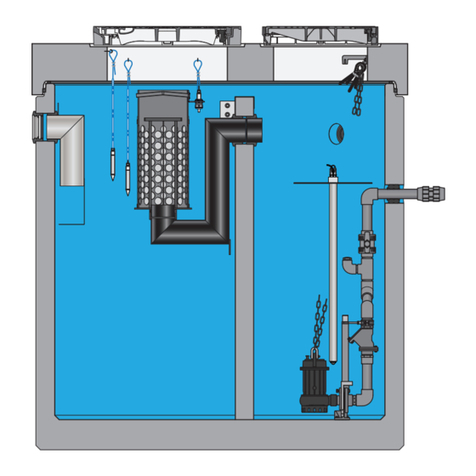

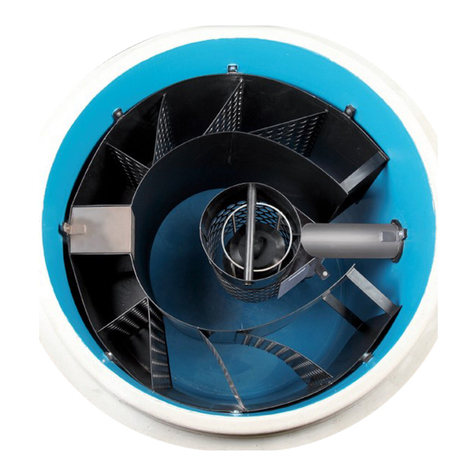

Installed devices (e.g. baes, inlet and

outlet parts, coalescence unit, etc.)

are intended for operation of separator

system and are not load bearing.

They must not be used as steps,

footholds or resting places for cleaning

equipment etc.

The separator system is dened as a

Zone 0 Explosion Hazard Area. Only

authorized, properly trained personnel

are permitted to perform work on the

electrical components of the separator

(where used).

Contact with wastewater

containing light liquids—e.g. during

maintenance—can lead to dry, irritated

skin, skin infections, headaches,

dizziness, nausea, vision problems,

loss of consciousness, and—in serious

cases—death. Ensure proper protective

clothing is used and immediately wash

any exposed skin.