2

Operation manual

ACO Clara

1 Introduction............................................................................3

1.1 What water we can treat .......................................................3

2 Safety......................................................................................4

2.1 General requirements regarding occupational safety .............4

2.2 Protection against accidents ..................................................4

2.3 Protection against infections caused by waste water.............4

3 Description of plant................................................................5

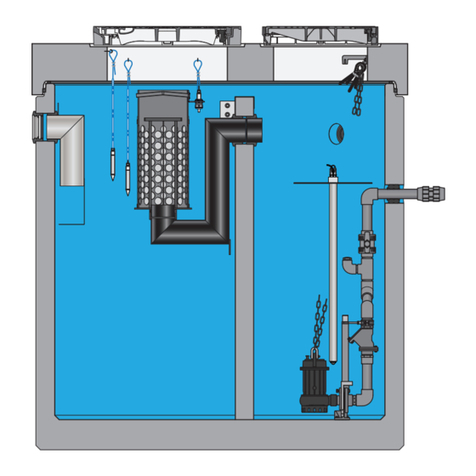

3.1 General description.................................................................5

3.2 Check of plant type, nameplate..............................................7

3.3 Cover ......................................................................................7

3.4 Inlet and outlet pipes..............................................................8

3.5 Air-lift pumps..........................................................................8

3.6 Blower.....................................................................................8

3.7 Mechanical pretreatment .......................................................9

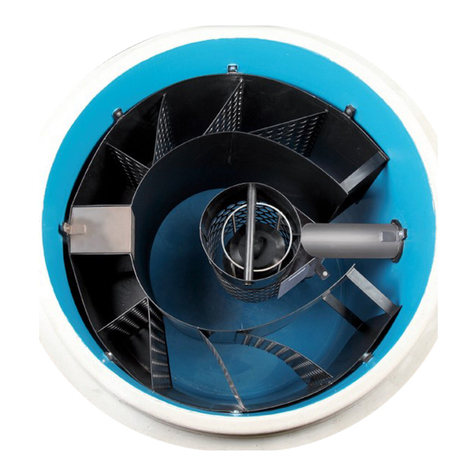

3.8 Activation tank .......................................................................9

3.9 Final sedimentation tank........................................................9

3.10 Ventilation pipe ......................................................................9

4 How the plant works ............................................................10

5 Installation ...........................................................................10

5.1 Transport and storage..........................................................10

5.2 Installation of blower ...........................................................10

5.3 Plant ventilation...................................................................10

5.4 Construction requirements....................................................10

5.5 Electrical installation ............................................................11

5.5.1 1 phase motor ......................................................................11

5.5.2 3 phase motor ......................................................................11

6 Operation and maintenance instructions.............................13

6.1 Plant commissioning ............................................................13

6.2 Records of plant operation...................................................13

6.3 Accessories for plant operation.............................................13

6.4 Description of individual checks and maintenance work......14

6.4.1 Check of blower function......................................................14

6.4.2 Aeration in activation tank ..................................................14

6.4.3 Functions of air-lift pumps....................................................15

6.4.4 Tank level of mechanical pretreatment, inlet pipe ................15

6.4.5 Level of final sedimentation tank and outlet object .............15

6.4.6

Quality of treated water

........................................................15

6.4.7

Check of concentration of activated sludge – sedimentation test

.....15

6.4.8 Check of treated water .........................................................15

6.4.9 Discharging of condensate water from aeration system ......16

6.4.10 Discharging of surplus sludge...............................................16

6.4.11 Discharging of mechanical pretreatment tank .....................16

6.4.12 Cleaning of tank walls..........................................................16

6.4.13 Cleaning of air-lift pumps.....................................................16

6.4.14 Replacement of aeration elements........................................17

6.5 Sampling ..............................................................................17

6.5.1 Sample at inlet .....................................................................17

6.5.2 Sample at outlet ...................................................................17

6.5.3 Sample of activated sludge...................................................17

6.6 Plant breakdown ..................................................................18

6.6.1 Short-term operational constraints ......................................18

6.6.2 Long-term shutdown ............................................................18

7 Troubleshooting....................................................................19

8 Certification..........................................................................20

9 Operation manual for blowers .............................................21

9.1 Installation ...........................................................................21

9.2 Ambience ..............................................................................21

9.3 Medium quality ....................................................................21

9.4 Piping ...................................................................................21

9.5 Storage .................................................................................21

9.6 Maintenance and service......................................................21

9.6.1 Filter element cleaning..........................................................22

9.6.2 Filter element replacement....................................................22

9.6.3 Valve box, diaphragm replacement......................................22

9.6.4 Reset of auto stopper............................................................23

9.6.5 Magnet replacement.............................................................24

9.7 Pictograms for maintenance and service..............................25

9.8

Maintenance and service for lamella blowers DT 4.25 and DT 4.40....

26

9.9

Maintenance and service for side channel blower SV 5.250/2

......30

9.10

Maintenance and service for side channel blower SV 8.190

..........34

List of contents: