Installation and Commissioning Guide - Package Ducted Variable Capacity Commercial

Doc. Part No. 0525-076 Ver. 3 210414

Installation and Commissioning Guide Variable Capacity Commercial

2

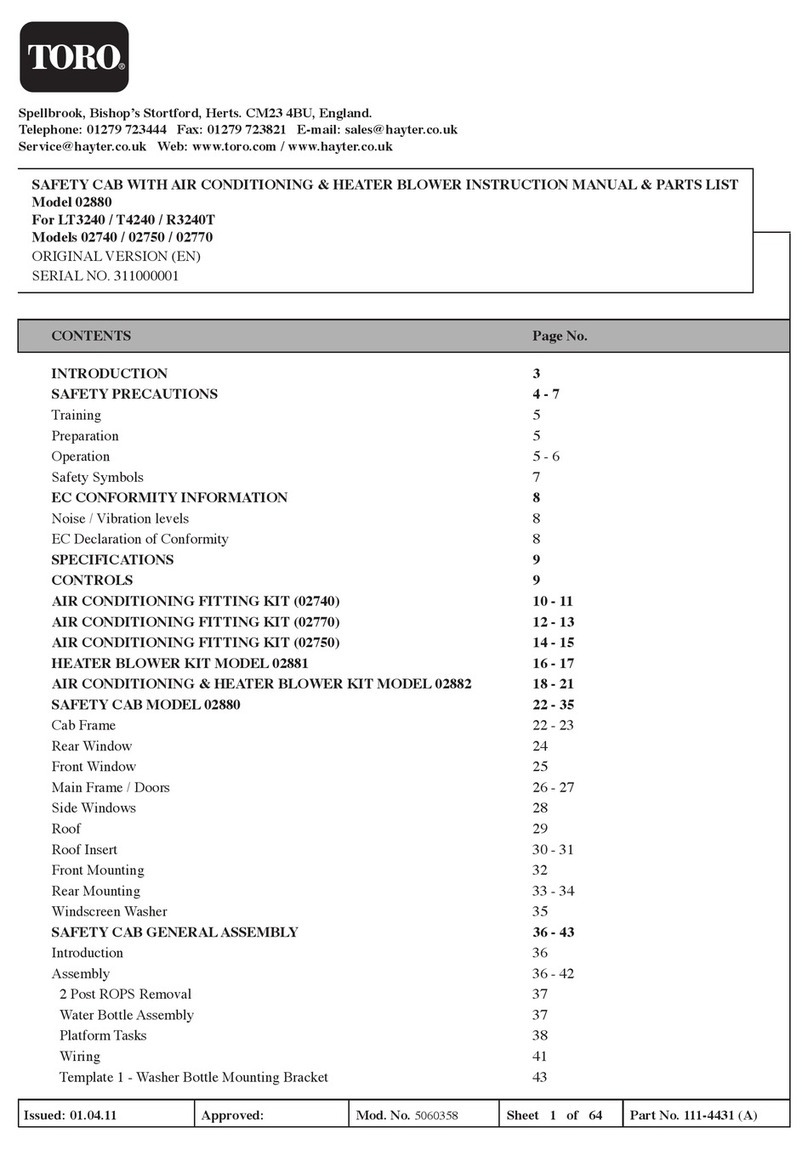

Table of Contents

01. Inspections................................................................................................................................. 3

02. General Information ................................................................................................................... 3

03. Safety Instructions .....................................................................................................................4

04. Installation Information.............................................................................................................. 5

05. Wall Control Operation Instruction Access.................................................................................. 7

06. Components Overview ............................................................................................................... 7

07. Package Unit Dimensions and Clearances.................................................................................... 9

. Package Models: PKVT / PKVT

. Package Models : PKVT / PKVT

08. Unit Lifting Procedure ............................................................................................................... 13

09. Package Unit Preparation........................................................................................................... 15

10. Condensate and Safety Tray Drainage Instructions ....................................................................18

11. Electrical Installation.................................................................................................................19

12. Package Unit Electrical Connection........................................................................................... 20

13. Maximum Cable Length ............................................................................................................. 21

. Wall Controller Options

. Wiring Configuration : Recommended

. Wiring Configuration : Alternate

14. Wiring Connections ................................................................................................................. 24

. LC- Wall Control Wiring Connections

. NEO Wall Control Wiring Connections

. LM-RS- Optional Sensor Wiring Connections

. AERSS Optional Duct Sensor Wiring Connections

15. Configuring and Commissioning Setup ..................................................................................... 26

. Menu and Navigation

. Configuring Compressor and Capacity (cnFg)

. Configuring Control Source (CtrS)

. Configuring Indoor Fan Setting (iduS)

16. Optional Output/Input Relay.....................................................................................................35

. Filter Indication Relay Output (CMI Board)

. Fan Run Indication Output (CMI Board)

. Optional Outside Air Damper Control Output (CMI Board)

. Third Party Control Input (CMI Board and/or Outdoor)

. Demand Response Management (Outdoor Board)

. Run and Fault Indication Output (Outdoor Board)

. Remote ON/OFF (Outdoor Board)

17. Indoor Fan Table And Fan Curve ................................................................................................41

. PKVT

. PKVT

. PKVT

. PKVT

18. Refrigerant Charging ................................................................................................................ 49

19. Maintenance Procedures ...........................................................................................................52

20. Maintenance Frequency Checklist............................................................................................. 54

21. Start Up and Commissioning Report ......................................................................................... 56