Adash A4910 Lubri User manual

A4910 – Lubri

Applications:

Monitoring and control of lubrication process

Measurement of rolling bearing condition

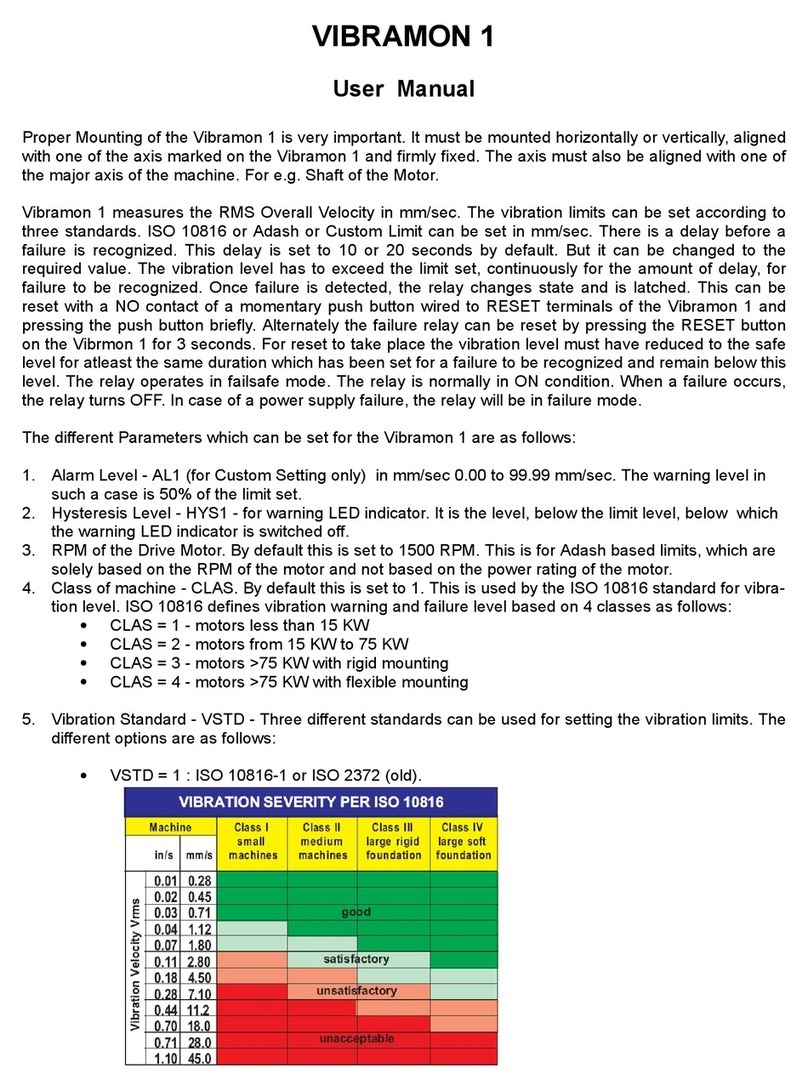

Ref. No.: 12112009

User’s Guide

ADASH spol. s r.o. A4910 – Lubri

ADASH Ltd., Czech republic, tel.: +420 596 232 670, fax: +420 596 232 671, email: info@adash.cz

For more technical and contact information visit www.adash.net, www.adash.cz

2

Contents:

Introduction ............................................................................................................................3

What Will You Get with Your Instrument? ...........................................................................4

Instrument and Accessories ............................................................................................................. 4

Before You Start.....................................................................................................................6

Quick Start..............................................................................................................................7

Two Possible Ways to Measure....................................................................................................... 7

Instrument Preparation..................................................................................................................... 8

Lubrication and Measurement.......................................................................................................... 8

Determining of Lubrication Interval and Amount of Lubricant........................................10

Goal of Maintenance in Lubrication Process.................................................................................. 10

Procedure for Lubrication Optimisation..........................................................................................10

How Much Lubricant Needs to Be Added ...................................................................................... 11

Instrument Description........................................................................................................12

Instrument Operation...................................................................................................................... 13

Error Indications ............................................................................................................................. 13

Changing Batteries......................................................................................................................... 13

Connecting of Headphones............................................................................................................ 15

Measurement pad instalation..............................................................................................16

Selection of Measurement Point .................................................................................................... 16

Preparation of Measurement Point ................................................................................................16

Types of Measurement Pads ......................................................................................................... 16

Pad Installation............................................................................................................................... 17

Bearing Condition Measurement for Diagnostic Purposes..............................................19

Technical Specifications Adash 4910 – Lubri ...................................................................20

ADASH spol. s r.o. A4910 – Lubri

ADASH Ltd., Czech republic, tel.: +420 596 232 670, fax: +420 596 232 671, email: info@adash.cz

For more technical and contact information visit www.adash.net, www.adash.cz

3

Introduction

There is an increasing demand for an instrument which is able to simply check lubrication of rolling

bearings and also the condition of these bearings.

Every machine does have in its specifications how much lubricant every one of its bearings uses in a

specific amount of operational hours. A task of each technician or engineer is to regularly check all the

lubricated points and maintain lubricant at sufficient levels. Either state, lack or excess of lubricant, are

harmful for a rolling element bearing. The result is always excessive stress on the bearing and

consequently excessive wear. Every lubricating point has a lubrication time interval (in hours of

service) and also an amount of lubricant that needs to be replenished. This manner of lubrication

control has a significant disadvantage.

The amount of lubricant that any bearing actually needs for proper operation changes during its

lifetime. Longer lubricating intervals in the case of a new machine are usually not sufficient for a

machine after several years of operation.

It is clear that it would be useful to be able to determine a state of a bearing somehow and replenish

only as much lubricant as is actually needed. Controlled lubrication increases bearing service life and

lowers costs for lubrication and repairs.

We have collected a large amount of knowledge by researching machine long-term operation and

lubrication here at ADASH and we have applied it in developing the instrument A4910 - Lubri. It is

simple to operate, and user’s training takes less than one hour. The main use of this instrument is in

the lubrication replenishment process. During this process the instrument measures the actual

lubrication condition of a bearing and tells the operator when the amount of lubricant is ideal. This way

it is ensured that we do not under or over lubricate.

When we use this instrument we can shorten recommended lubrication intervals, since the instrument

always exactly determines the ideal amount of lubricant needed.

As a result of using the A4910-Lubri instrument, your machines will be maintained in their best

lubrication condition. The instrument enables you to make the whole lubricating process simpler and it

normally reduces the consumption of very expensive lubricants.

ADASH spol. s r.o. A4910 – Lubri

ADASH Ltd., Czech republic, tel.: +420 596 232 670, fax: +420 596 232 671, email: info@adash.cz

For more technical and contact information visit www.adash.net, www.adash.cz

4

What Will You Get with Your Instrument?

Instrument and Accessories

The instrument case contains:

- instrument A4910 - Lubri

- lubrication and bearing condition sensor

- magnetic base for sensor

- coiled cable to connect sensor

- headphones

- 1.5V alkaline battery

The complete lubrication set

ADASH spol. s r.o. A4910 – Lubri

ADASH Ltd., Czech republic, tel.: +420 596 232 670, fax: +420 596 232 671, email: info@adash.cz

For more technical and contact information visit www.adash.net, www.adash.cz

5

Application example

ADASH spol. s r.o. A4910 – Lubri

ADASH Ltd., Czech republic, tel.: +420 596 232 670, fax: +420 596 232 671, email: info@adash.cz

For more technical and contact information visit www.adash.net, www.adash.cz

6

Before You Start

1. Never connect any other type of sensor than ICP into the socket marked ICP!

If unsure, contact your supplier.

2. Never plug the A4910 into 110 - 230 V voltage!

3. To power the A4910, use batteries (rechargeable batteries) with max. nominal voltage of 1.5

V!

4. To power the A4910 use only alkaline or rechargeable (NiCd, NiMH) batteries.

Regular carbon-zinc batteries are not suitable.

Ignoring any recommendations mentioned below may cause failure of the instrument.

Operating with power higher then 24 V can cause an accident.

WARNING!

Use correct battery polarity.

Incorrect polarity will cause destruction of the

instrument!

ADASH spol. s r.o. A4910 – Lubri

ADASH Ltd., Czech republic, tel.: +420 596 232 670, fax: +420 596 232 671, email: info@adash.cz

For more technical and contact information visit www.adash.net, www.adash.cz

7

Quick Start

The aim of this chapter is to introduce you to A4910-Lubri, and, without reading a complete User’s

Guide, try this instrument in practice.

Two Possible Ways to Measure

A sensor (a standard accelerometer with sensitivity of 100mV/g and ICP power), which needs to be

mounted on a bearing housing, is used to measure lubrication.

We have two possibilities how to do this:

1 The sensor is mounted on a lubrication head.

This option enables a quick service since the lubrication head is transferred together with the sensor.

The disadvantage is a partial loss of sensitivity, since the lubrication head attenuates the measured

signal.

2 The sensor is mounted next to lubrication point on a bearing housing (measurement pad

recommended).

This option enables a perfect measurement. The disadvantage is a longer preparation, since the

lubrication head and sensor must be mounted separately.

1. Sensor is on the lubrication head 2. Sensor is mounted next to lubrication point

If vibration diagnostic measurements are performed on a machine, then a measurement pad is already

mounted. This pad can be used also for lubrication measurements.

A procedure for mounting of a measuring base is shown at the end of this Guide.

ADASH spol. s r.o. A4910 – Lubri

ADASH Ltd., Czech republic, tel.: +420 596 232 670, fax: +420 596 232 671, email: info@adash.cz

For more technical and contact information visit www.adash.net, www.adash.cz

8

Instrument Preparation

The preparation of this instrument for measurement is easy. All you need to do is to put in batteries

and plug in the lubrication sensor and screw it on a magnetic base.

Remark: The battery (rechargeable battery) space is behind a door in the base of the instrument.

Open the door by pressing its lower edge (the edge with hinge) then you can easily replace the

batteries – see chapter: Instrument Description – Battery Change.

Plugging in the Lubrication Sensor

Lubrication measurements require plugging in a lubrication sensor with ICP power. The sensor must

be a standard accelerometer with 100 mV/g sensitivity. The instrument is equipped with its own

source of ICP power for connected sensor.

The sensor needs to be connected at the right side plug using the supplied cable. Then a magnetic

base needs to be screwed on to the sensor.

Top view of the connectors

Lubrication and Measurement

If the instrument is ready, we need to attach a lubrication head. If a sensor is not a part of lubrication

head, we attach it, by using a magnetic base, to a formerly prepared and glued measuring base. Do

not forget to remove the cover of magnetic base, which protects the magnet from weakening in

storage.

Switch on the instrument by pressing Mode. Provided that the batteries are OK, the instrument display

will show running bands and greasers (red and green). Then the instrument will automatically measure

an actual lubrication state. If your headphones are connected, you will be able to clearly hear the

bearing noise. Using and arrows you can increase/decrease its volume. On the left side of the

display is a column, whose height indicates a bearing lubrication state. After the instrument is switched

on, it always reaches a maximum level. We need to slowly start adding lubricant, while monitoring the

height of the column on the display and the noise in the headphones. Usually there is not much going

on in the beginning, which means that the lubricant is pushed toward the bearing, however it is not

there yet. At the moment when the lubricant reaches the bearing, the column decreases (usually its

upper red part disappears and only the green lower part remains) and noise in the headphones

decreases also. We need to add a little more lubricant, and if there is no further decrease, we end the

lubrication process.

If, at the beginning of measurement, the greaser in the lower right hand corner starts to blink, then the

signal from a bearing is very low. We have either new or a very well greased bearing. In this case we

suggest using headphones to finish lubrication.

Before we start lubricating another bearing we need to reset after the previous measurement. It is

connector to plug

in the sensor

connector to plug in

headphones

(stereo jack 3.5mm)

ADASH spol. s r.o. A4910 – Lubri

ADASH Ltd., Czech republic, tel.: +420 596 232 670, fax: +420 596 232 671, email: info@adash.cz

For more technical and contact information visit www.adash.net, www.adash.cz

9

necessary, since, during bearing operation, values showing bearing status are different for every

bearing. The values are different even for bearings of the same type used on different machines or

under different loads. Reset is done by a short push of the Mode button. A lubrication value in the

upper right display corner will start blinking during reset.

Complete switch-off is done by a long push of the Mode button.

Picture on the left shows greasers signalling proper instrument start. Middle picture shows

measurement before lubrication and right shows measurement after lubrication

Warning!!! If the display stays off after switching on the instrument, the batteries are weak – change

them!

New measurement

is signalled by

blinking

Blinking signals a low

signal level from

bearing

ADASH spol. s r.o. A4910 – Lubri

ADASH Ltd., Czech republic, tel.: +420 596 232 670, fax: +420 596 232 671, email: info@adash.cz

For more technical and contact information visit www.adash.net, www.adash.cz

10

Determining of Lubrication Interval and

Amount of Lubricant

Goal of Maintenance in Lubrication Process

The goal of maintenance is a long lifetime of rolling bearings. We need to optimise lubrication to

achieve this. To achieve the best possible state of lubricated bearings and save lubricant at the same

time, we need to determine regular intervals, when we are going to perform lubrication. Another

question is the amount of lubricant for each of the lubrication points.

Starting points are intervals and amounts determined by a manufacturer. We had performed a large

amount of testing on bearings directly in manufacturing. We have found that the intervals, which are

determined by manufacturers, are always too long, and that at the end of these intervals the bearings

are not working under optimum condition.

Procedure for Lubrication Optimisation

The A4910 Lubri instrument enables you to measure an actual working condition of a bearing (a

numerical value up on the display). We can utilise this measurement for optimisation of lubrication,

using the following steps:

1 We need to lubricate a machine thoroughly.

2. Then we measure and record a (reference) value of the bearing condition.

3. We need to repeat this measurement regularly in 1/10th lubrication intervals recommended by a

manufacturer.

4. If the condition value of the bearing increases to double of its reference value, then further

lubrication is needed, and time from reference measurement to this new lubrication is our new

optimum lubrication interval.

Remark: In case that we overlubricate a bearing at the initial reference lubrication, the bearing

condition value can initially decrease, until the amount of lubricant in the bearing reaches an optimum

(minimum) value. Than we use this time and value as our initial reference.

Example:

The manufacturer recommended lubrication interval is 600 service hours. The reference value is

0.25g. The control measurements are performed every 60 service hours (see Table):

REF 0.25

60 0.26

120 0.29

180 0.35

240 0.51

The measured value reached double of the reference value in 240 service hours. Optimum lubrication

interval is then 240 service hours.

ADASH spol. s r.o. A4910 – Lubri

ADASH Ltd., Czech republic, tel.: +420 596 232 670, fax: +420 596 232 671, email: info@adash.cz

For more technical and contact information visit www.adash.net, www.adash.cz

11

How Much Lubricant Needs to Be Added

The result of lubrication interval optimisation procedure is also the lowest value of a bearing condition.

Our goal is to reach this value by regular lubrication. We add lubricant long enough to reach this

reference value.

We need to realise, however, that a bearing is being worn out, and so its working condition worsens.

That is why it is not possible to constantly reach, during its lifetime, its original reference value during

lubrication.

The lubrication rule is then as follows:

Lubricate while the bearing condition value decreases, then stop.

ADASH spol. s r.o. A4910 – Lubri

ADASH Ltd., Czech republic, tel.: +420 596 232 670, fax: +420 596 232 671, email: info@adash.cz

For more technical and contact information visit www.adash.net, www.adash.cz

12

Instrument Description

Adash 4910 – Lubri.

Note: The A4910-Lubri instrument has the LB/TRUE RMS measurement method preset, this method

is capable of numerical evaluation of a bearing state.

Output headphone

connector:

Stereo jack 3.5mm

Input connector for

lubrication sensor

connector: BINDER

712

Volume down

Bar indicating

lubrication state

ON/OFF Switch

Volume up

Batteries

(rechargeable

batteries)

measured value

ADASH spol. s r.o. A4910 – Lubri

ADASH Ltd., Czech republic, tel.: +420 596 232 670, fax: +420 596 232 671, email: info@adash.cz

For more technical and contact information visit www.adash.net, www.adash.cz

13

Instrument Operation

Mode button

Mode button is used to switch the instrument on/off and for measurement reset. The button needs to

be pushed for a longer time to switch off.

Buttons

and

These buttons are use to control volume in headphones. Arrow increases volume, arrow

decreases it.

Error Indications

Errors are indicated on an instrument display.

If there is a problem with cable or sensor, the display will show “ICP ERR“ (see picture). If we get an

ICP ERR, we need to check:

- connecting cable (broken or short circuit)

- sensor

If there is another internal fault, the display will show “CPU ERR“ (see picture). If the error constantly

repeats itself, contact your supplier or manufacturer.

Sensor and instrument power supply errors

Changing Batteries

To power the instrument, use AA-size alkaline batteries or NiMH rechargeable batteries with

nominal voltage of max. 1.5 V. Use of regular carbon-zinc batteries is not recommended.

The batteries are accessible after you open a small lid on a bottom of the instrument. You can open

the lid by pushing on its bottom side (hinge side), the upper side then opens easily – see the picture.

DO NOT APPLY FORCE!!! Correct polarity is shown in the picture.

Do not forget to switch the instrument off before you open the battery compartment lid!

Never handle the batteries when the instrument is switched on!

ADASH spol. s r.o. A4910 – Lubri

ADASH Ltd., Czech republic, tel.: +420 596 232 670, fax: +420 596 232 671, email: info@adash.cz

For more technical and contact information visit www.adash.net, www.adash.cz

14

Battery compartment opening

Battery placement

1 Push gently

2 Open

ADASH spol. s r.o. A4910 – Lubri

ADASH Ltd., Czech republic, tel.: +420 596 232 670, fax: +420 596 232 671, email: info@adash.cz

For more technical and contact information visit www.adash.net, www.adash.cz

15

Correct polarity

Connecting of Headphones

The instrument is equipped by a 0.5 W amplifier for listening to a bearing noise. We can connect the

headphones by a stereo 3.5 mm jack marked PHONES on the top of the instrument (see picture in the

sensor connecting chapter). Suitable volume can be set by arrows or .

When the instrument is switched on or off, range is changed, or the sensor is connected or

disconnected, a short, unpleasant crack can be heard due to a transitional effect. This is not a defect.

You can use any headphones with nominal impedance higher than 8 Ω.

Be careful not to overload the headphone amplifier by excessive volume. This will distort a

signal in the headphones!

ADASH spol. s r.o. A4910 – Lubri

ADASH Ltd., Czech republic, tel.: +420 596 232 670, fax: +420 596 232 671, email: info@adash.cz

For more technical and contact information visit www.adash.net, www.adash.cz

16

Measurement pad instalation

Selection of Measurement Point

Two conditions are important for exact measurement of lubrication state.

Firstly, to pick a suitable attachment place for the lubrication sensor, i.e. place as close as possible to

the bearing. The bearing housing is ideal for this. If this is not possible, we should choose a part of a

machine, which is in as firm as possible contact with the bearing. Covers etc. are not suitable as

measurement points – the points have to be as rigid as possible.

The other condition is preparation of the measurement place – gluing on a measurement base.

Note: If your company performs vibration diagnostics on its machines, you can utilize measurement

points that have been created for this purpose for bearing lubrication measurements also.

Preparation of Measurement Point

In order to obtain a quality measurement, we need to properly prepare these places. It is necessary, in

regularly performed lubrications, to always attach a sensor the same way at the same place. In order

to perform bearing lubrication measurements, we need to attach a sensor through magnetic base or,

even better, screw it on. For practical reasons most users use the magnetic base, since screwing

takes more time. The magnetic base is a very strong magnet firmly screwed on to the sensor, which is

then magnetically attached to a surface of a machine. The quality of the attachment significantly

influences the measurement results. If the sensor rocks or jumps etc. the measurement is useless.

Also a thick layer of paint or corrosion lowers the usefulness of a measurement. The surface of the

magnetic base is carefully ground and the same type of surface is needed on the machine. This is, of

course, practically impossible, since we are only capable to create an evenly ground surface of 3x3 cm

in a workshop. Even if we were able to create such a surface, it would not last since a quality of

bearing housing steel (for example) is not high, and it quickly succumbs to corrosion. This renders the

place unusable.

The solution is to use measuring pads. They are small cylinders with diameter of approx. 26 mm and

10 mm tall with ground surface. They are made from magnetic stainless steel. They are glued to

appropriate places on a machine with a special glue, which ensures perfect transfer of high frequency

vibration. The pad is covered by a plastic cover, which is only removed at the time of measurement.

Another advantage of the cover is that in case of a machine being painted your measurement point is

preserved. Painting over the measuring pad destroys it!

All you need to do before gluing one of the pads is to degrease and roughly grind a machine surface in

an appropriate spot. The pads last indefinitely, or until they are forcibly removed.

Types of Measurement Pads

We supply two basic types of the measurement pads for measuring location preparation. They are: a

simple measuring pad for easily accessible places on a machine and special T-pad for electric motors

ADASH spol. s r.o. A4910 – Lubri

ADASH Ltd., Czech republic, tel.: +420 596 232 670, fax: +420 596 232 671, email: info@adash.cz

For more technical and contact information visit www.adash.net, www.adash.cz

17

(for attachment at cooling ribs). Both pads have an M6 threads for screwing on the sensor.

Pad Installation

You will need the following: angle grinder, files, sand paper, degreaser (spirits, thinner), measurement

pads, and glue.

The surface where you need to attach the pad needs to be prepared as follows:

- remove paint, corrosion and eventual unevenness by grinding

- degrease

Both types of pads are being attached to a measuring location by METAL TECH SG glue.

See www.thortex.com - product

You can use other glues with similar properties.

It is dual component epoxy glue with characteristics suitable for this purpose.

The two components react chemically when handled and after proper mixing and drying create a hard

material, which is resistant to pressure, temperature and humid environment.

In case of the simple pad proceed as follows: With a sharp knife cut about 3 mm thick slice and by wet

fingers work into homogeneous matter. From this make about 2 – 3 mm thick cylinder and put it on a

rough side of the pad.

Then press the pad onto the previously prepared, cleaned spot and turn back and forth under steady

pressure to glue it onto the machine. Make sure the glue is being pushed out evenly around the

circumference of the pad. The purpose is to create as thin a layer of glue as possible at the

attachment location. ! WARNING: DO NOT PUSH OUT ALL THE GLUE !

Extra glue can be removed or smoothed around the pad. Cover the pad by its cover.

When using T-pad the amount of glue depends on the distance between cooling ribs, so it is not

possible to exactly determine this amount. Just as with the simple pad you have to clean and

degrease the space between ribs where the T-pad is going to be attached. This space needs to be

filled by sufficient amount of glue so after inserting of the T-pad only the cylindrical part of the pad

would stay exposed. Pack the glue around the pad then cover the pad with a cover.

ADASH spol. s r.o. A4910 – Lubri

ADASH Ltd., Czech republic, tel.: +420 596 232 670, fax: +420 596 232 671, email: info@adash.cz

For more technical and contact information visit www.adash.net, www.adash.cz

18

Placement of measurement pads on a machine

ADASH spol. s r.o. A4910 – Lubri

ADASH Ltd., Czech republic, tel.: +420 596 232 670, fax: +420 596 232 671, email: info@adash.cz

For more technical and contact information visit www.adash.net, www.adash.cz

19

Bearing Condition Measurement for Diagnostic

Purposes

This instrument also takes measurements of rolling bearing conditions in addition to lubrication

measurements. For this purpose an actual value of bearing condition is displayed at the upper right

side of the display. It is possible to follow a time trend, if these values are recorded or entered into a

computer. If you want to successfully diagnose rolling bearing conditions use the following

suggestions:

1. Make a list of machines and bearings you want to measure. Mark each measuring place.

2. Measure every bearing at the same place under the same operational conditions.

3. Mark the values only after proper bearing lubrication.

4. Determine a reference value for each bearing. Measure the reference value at a time when the

bearing is in a good operational condition (the best is after a successful installation of a new bearing).

5. Record all measurements into a notebook or computer.

6. We are capable to determine conditions of rolling bearings based on increasing values:

- if there is an increase of 100% against a reference value, we need to understand it as a warning and

the bearing should be investigated in detail at the earliest opportunity,

- if there is an increase of more than 400%, a critical change in operational conditions of the bearing

took place. This bearing should be replaced as soon as possible.

ADASH spol. s r.o. A4910 – Lubri

ADASH Ltd., Czech republic, tel.: +420 596 232 670, fax: +420 596 232 671, email: info@adash.cz

For more technical and contact information visit www.adash.net, www.adash.cz

20

Technical Specifications:

Input: - 1x ICP powered accelerometer with 100 mV/g sensitivity for measurement and recording of

lubrication

Output: - 1x monoaural AC signal 8 Ω/ 0,5 W for external headphones (listening to measured

signal)

Power: - 2x1,5V (AA alkaline batteries) or 2x1,2V (NiMH AA rechargeable batteries)

Consumption: - max. 400 mA using headphones

Dimensions: - 150 x 60 x 35 mm

Weight: - approx. 250 g

Technical Specifications Adash 4910 – Lubri

Table of contents

Other Adash Measuring Instrument manuals

Adash

Adash A4900 - Vibrio M User manual

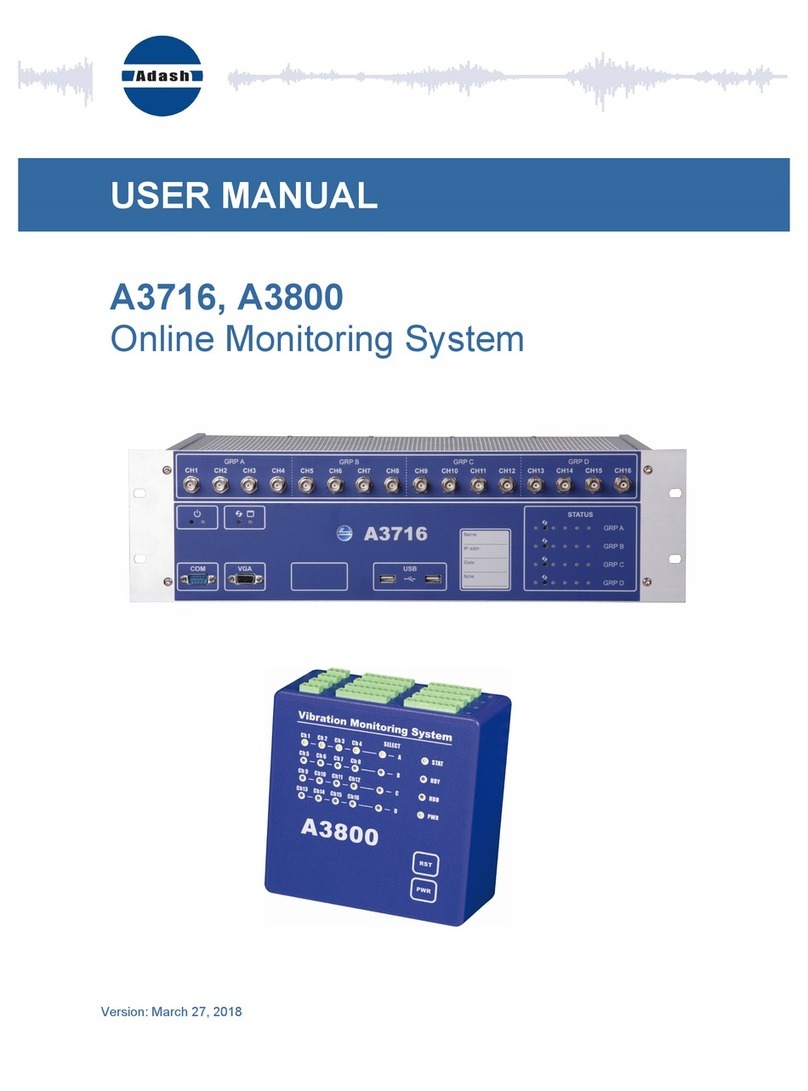

Adash

Adash A3716 User manual

Adash

Adash 4300 VA3Pro User manual

Adash

Adash VA5 Pro User manual

Adash

Adash 4900 Vibrio III User manual

Adash

Adash 4300 - VA3 User manual

Adash

Adash A3716 User manual

Adash

Adash A4900 - Vibrio M User manual

Adash

Adash 4900 Vibrio M User manual

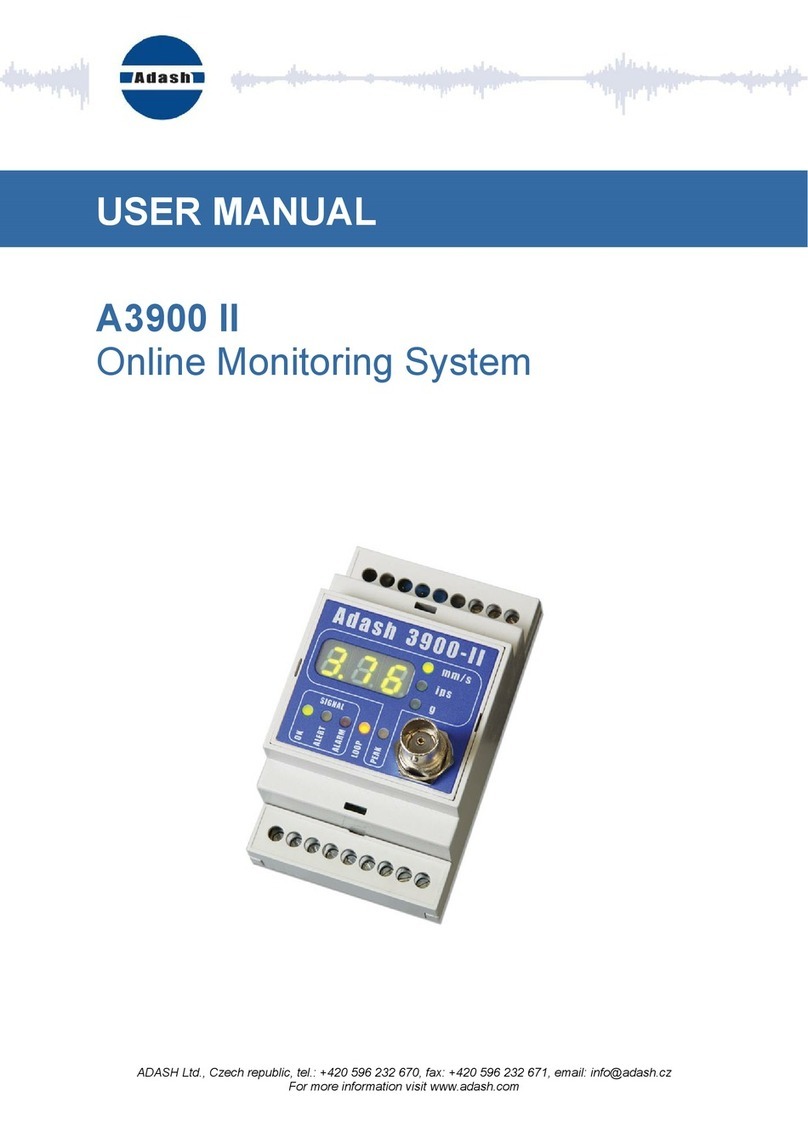

Adash

Adash A3900 II User manual