ABB CP600-eCo User manual

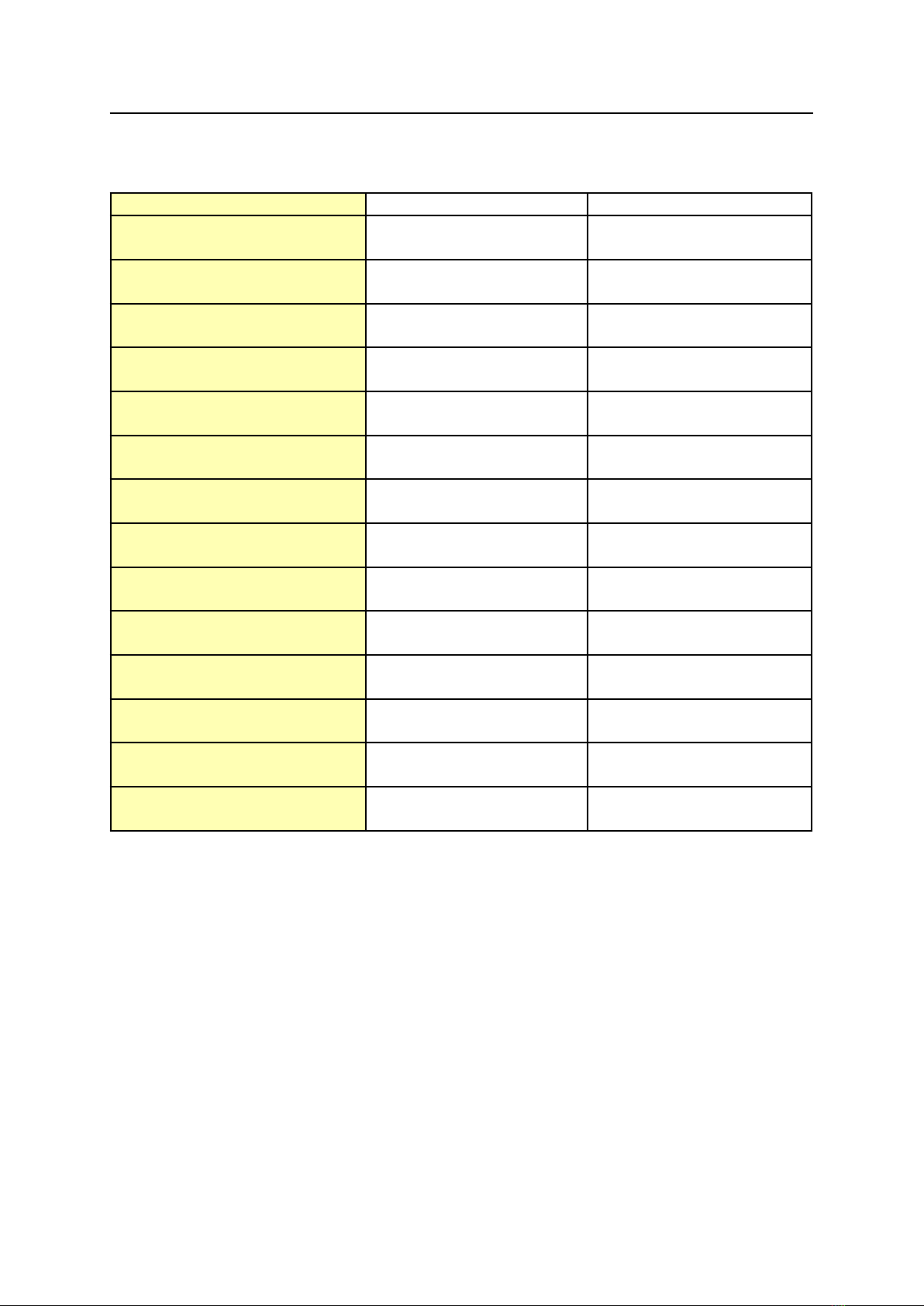

Other ABB Control Panel manuals

ABB

ABB CP660-x User manual

ABB

ABB ControlMaster CM10 Use and care manual

ABB

ABB ACS-AP-x User manual

ABB

ABB 6136/30M-500 User manual

ABB

ABB CP 600 Series User manual

ABB

ABB ACS580 Series User manual

ABB

ABB Welcome IP IPTouch 7" Series User manual

ABB

ABB CP600-Pro User manual

ABB

ABB Welcome IP IPTouch 7 Series User manual

ABB

ABB AC-AP Series User manual

ABB

ABB ACS850 series Troubleshooting guide

ABB

ABB CP420B User manual

ABB

ABB 6136/30M-101 User manual

ABB

ABB CP405 User manual

ABB

ABB ACSM1 Series User manual

ABB

ABB Eurofire EN54 Quick start guide

ABB

ABB Controlpanel User manual

ABB

ABB CP435 User manual

ABB

ABB CP430 User manual

ABB

ABB OPMP-01-Kit User manual

Popular Control Panel manuals by other brands

Mitsubishi Heavy Industries

Mitsubishi Heavy Industries SC-SL4-AE2/1 user manual

Sminn

Sminn BOX L VF1L EI instruction manual

Balboa

Balboa TP600 user manual

Nice

Nice HSCU1 Instructions and warnings for installation and use

Truma

Truma CP plus installation instructions

Crowcon

Crowcon Vortex Installation, operation and maintenance