99

TIGHT

H M L

TIGHT

H M L

TIGHT

H M L

TIGHT

H M L

TIGHT

H M L

TIGHT

H M L

TIGHT

H M L

TIGHT

H M L

TIGHT

TIGHT

TIGHT

2

3

1

1

2

2

1

click

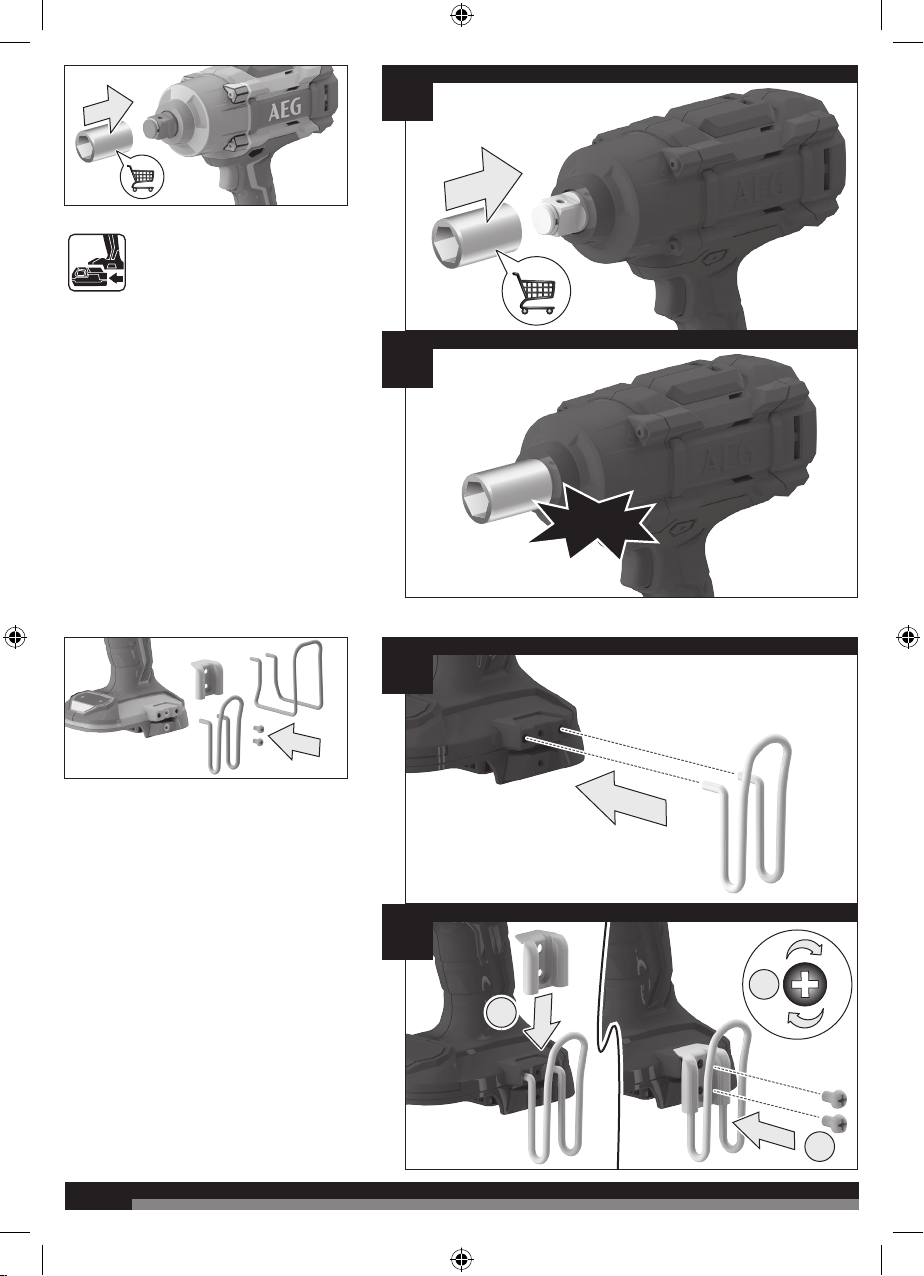

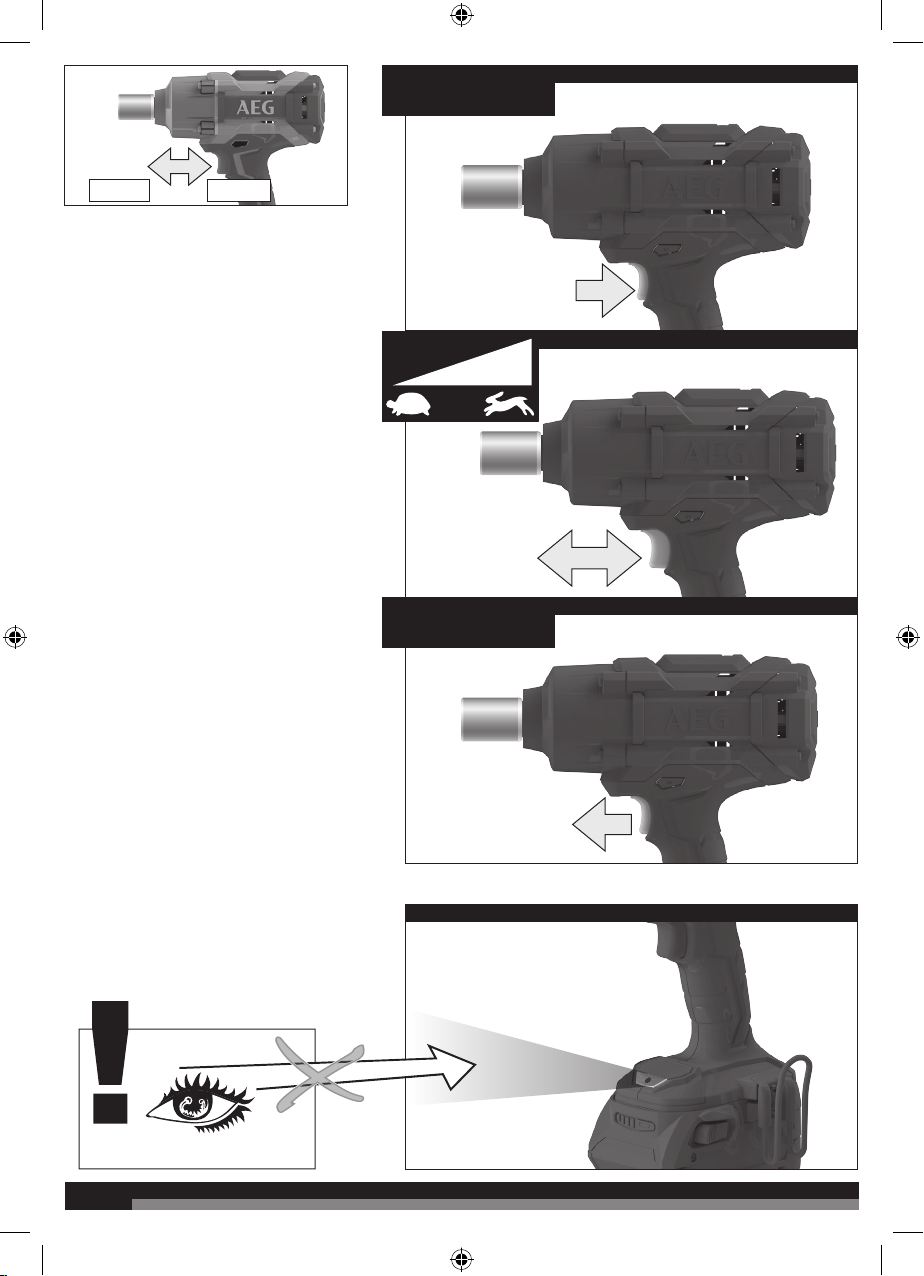

Remove the battery pack before starting any

work on the machine.

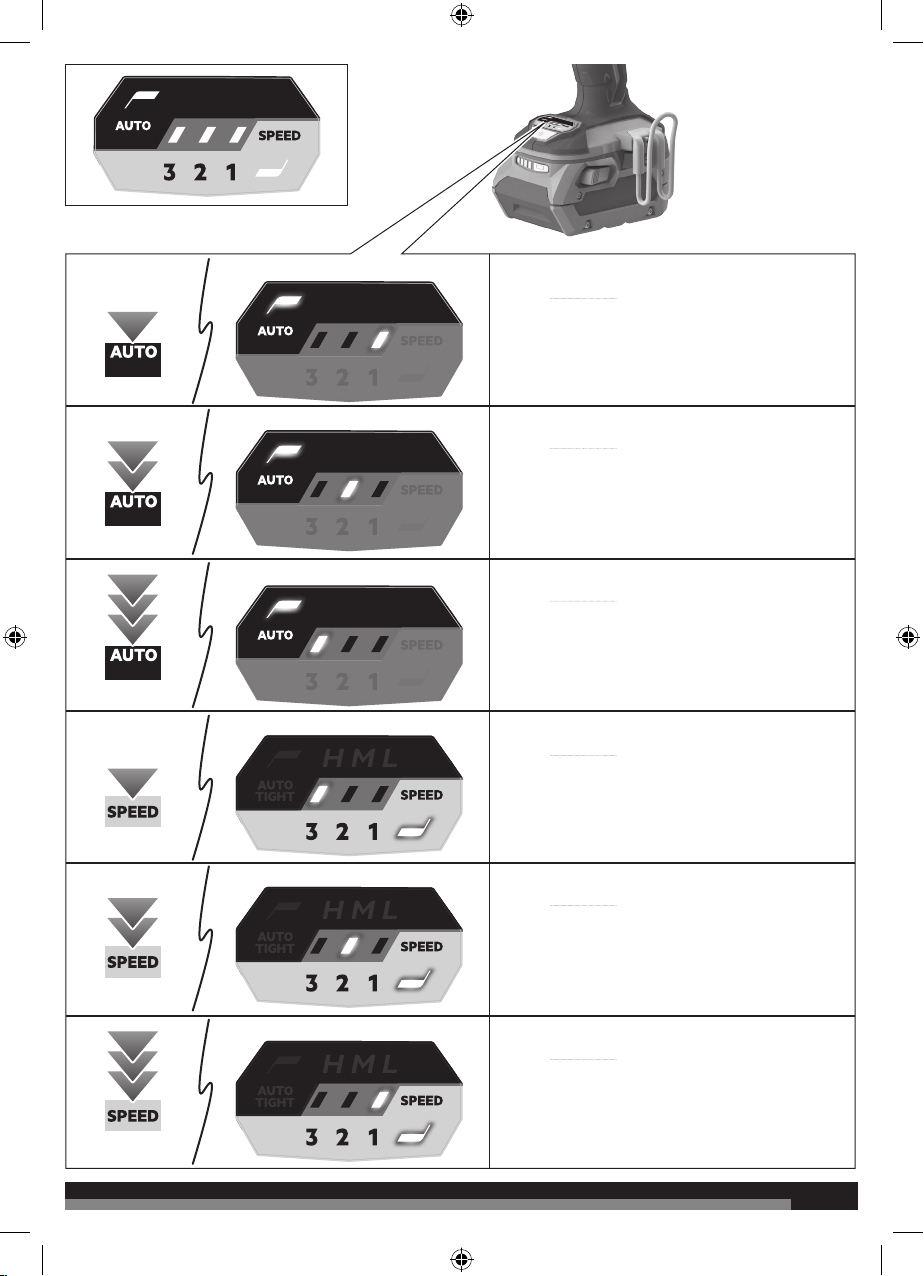

T mode: low torque

T mode: medium torque

T mode: maximum torque

Speed mode

Speed mode

Speed mode

T mode: low torque

Torque 200 Nm

Use this mode to drive small fasteners when low torque

is required. In this mode, the product will automatically

stop after it has impacted on the fastener, thus preventing

damage to the workpiece or fastener.

T mode: medium torque

Torque 790 Nm

Use this mode to drive medium-sized fasteners when

medium torque is required. In this mode, the product will

automatically stop after it has impacted on the fastener,

thus preventing damage to the workpiece or fastener.

T mode: maximum torque

Torque 1230 Nm

Use this mode to drive large fasteners when high torque

is required. In this mode, the product will automatically

stop after it has impacted on the fastener, thus preventing

damage to the workpiece or fastener.

Speed mode: 3

Torque 1660 Nm

Use this mode to drive large fasteners when maxmium

force and speed are required.

Speed mode: 2

Torque 900 Nm

Use this mode to drive medium-sized fasteners when

medium force and speed are required.

Speed mode: 1

Torque 115 Nm

Use this mode to drive small fasteners when lowest speed

and force are required.