7

5. OPERATION

5.1. SET POINT IN COOLING MODE. PARAMETER 1STF

(factoryset)=7°C/44.9°F,∆t=9°C.

5.2. SET POINT IN HEATING MODE. PARAMETER 3STC

(factoryset)=45C/113°F,∆t=9°C.

Iftheunitpowersupplyisrestoredafteratemporaryinterruption,

thesetmodewillbekeptinthememory.

5.3. COMPRESSOR START-UP DELAY

Twofunctionshavebeenpreparedtopreventcompressorstart‐ups

thataretooclose.

‐ Minimumtimefromlastswitch‐off180seconds.

‐ Minimumtime fromlastswitch‐on300seconds.

5.4. CIRCULATION PUMP

Thecircuitboarddeliversanoutputforpumpmanagement,which

startsoncommissioningandremainsonforatleast150seconds

andcontrolsthestateoftheprobes.

Afterthefirst40secondsofpumpoperationthewaterflowswitch

closesandtheunitstarts,whenthewaterflowrateisinnormal

workingconditions,thewaterflowratealarmfunctionsareacti‐

vated(differentialpressureswitchorflowmeter).Whenthema‐

chineentersstand‐bymode,thepumpremainsonfor30secand

controlstheflowmeterorthepressureswitch

5.5. FAN SPEED CONTROL

DCPX ACCESSORY

COOLING OPERATION AT LOW AMBIENT CONDITIONS

AND HEATING OPERATION AT HIGH AMBIENT CONDI-

TIONS.

Toallowcorrectfunctioningoftheunitatdifferentexternaltem‐

peratures,theMODUCONTROLbyreadingthepressureviathe

pressureprobe,controlstherotationspeedofthefans,thusallow‐

ingtoincreaseand/ordecreaseheatexchange,keepingthecon‐

densationorevaporationpressuresmoreorlessconstant.Thefan

functionsindependentlywithrespecttothecompressor.Remem‐

berthattheDCPXismandatoryfortheproductionofDHW.And

coolingbelow20°C/68°F.

5.6. ANTI-FREEZE ALARM

Theanti‐freezealarmisneveractiveifthemachineisofforinstand

‐bymode.Inordertopreventbreakageoftheplateheatexchanger

duetofreezingofthewateritcontains,theMODUCONTROLstops

thecompressorifthetemperaturedetectedbytheprobepostioned

attheoutletoftheheatexchangerandininlettothechilleris

below+4°C/39°F.

THISANTI‐FREEZESETTEMPERATURECANONLYBEVARIEDBYAN

AUTHORISEDAFTER‐SALESCENTREANDONLYAFTERHAVINGCHECKED

THATTHEREISANTI‐FREEZESOLUTIONINTHEWATERSYSTEM.

Theinterventionofthisalarmdeterminescompressorstop

andnotpumpblock,whichremainsactivealongwiththeswitch‐on

oftheresistanceifinstalled.Torestorenormalfunctionsthetem‐

9.Thevoltageiswithinthetoleranceof10%oftheunitnominalvalue

10.Earthingiscorrectlymade.Allelectricandhydraulicconnectionsare

correctlytightened.

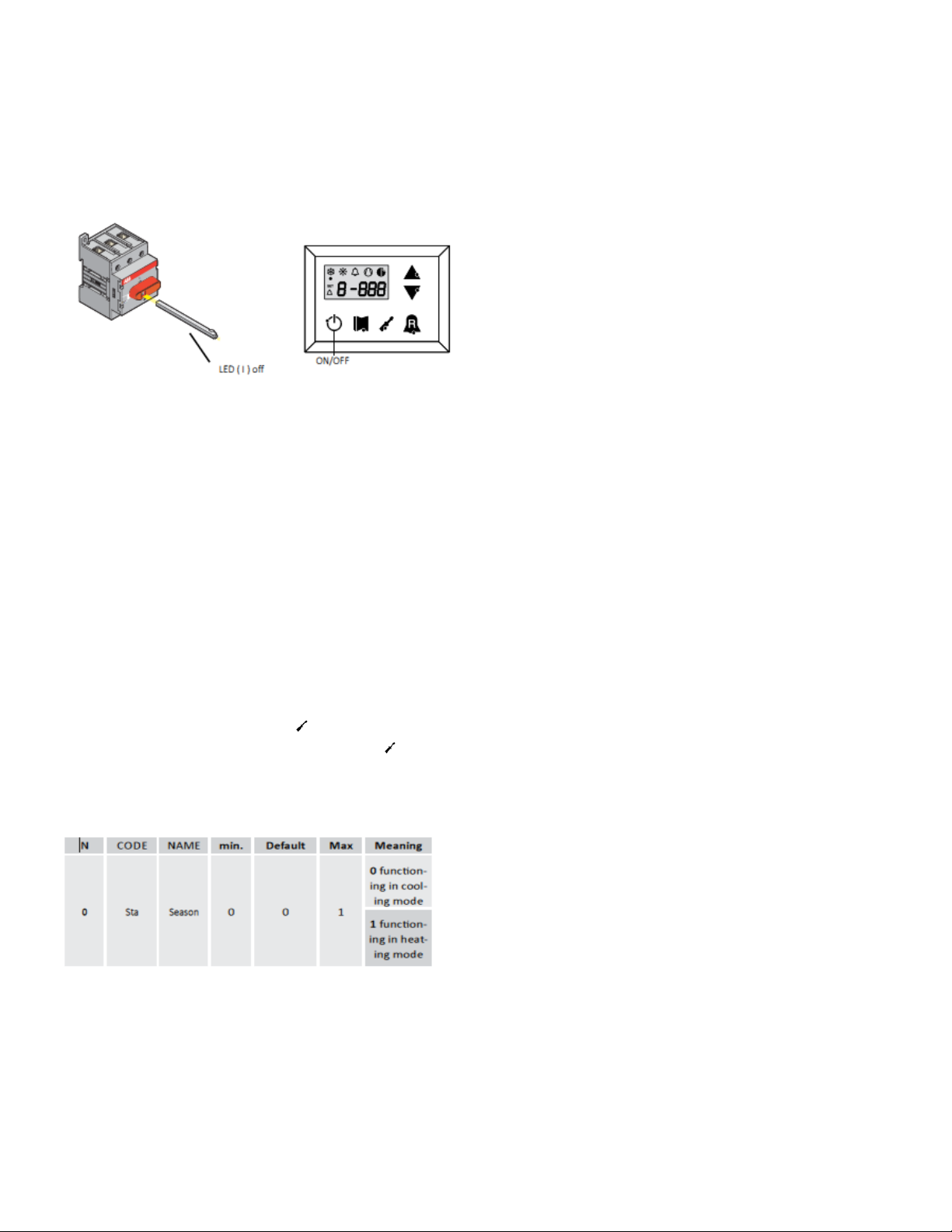

4.2. MACHINE COMMISSIONING

‐Closetheelectriccontrolboardhatch.

‐PositiontheappliancemasterswitchatON.

‐Makesurethattheauxiliaryswitchcontact(IA)

(seewiringdiagram)isopen(ifused,andthedisplayLED(I)Amustbeoff.

‐PresstheONkeyfor3sectoswitchthemachineon.

4.3. SEASON CHANGEOVER, OPERATION PARAMETERS

‐Foreveryseasonchange,checkthatthefunctioninglimitsliewithinthe

properlimits.

‐Checkthatthecompressorinputcurrentislowerthanthemaximum

indicatedinthetechnicaldatatable.

‐Makesurethatthevoltagevaluelieswithinthepre‐fixedlimitsandthat

unbalancebetweenthethreephases(three‐phasepowersupply)isnot

above3%.

SEASON CHANGEOVER FROM PANEL ON MACHINE

AccesstheUSERSETlistbytouchingtheinsertpasswordkey000

(alreadydisplayed);justconfirmbyre‐pressingthekey

TheparameteraffectedistheSta,changingthevalue0and1willchange

theoperationfromcoolingtoheatingaccordingly.Forfurtherinforma‐

tionrefertotheUSERMANUAL

SEASON CHANGEOVER FROM PR3

Justactdirectlyontheswitch.Themachineswitchesoffautomatically‐

andswitchesback‐onwiththeselectedfunctioningmode.Advancebased

onthetimeframeforthecompletionofworksforthesystem.Priorto

theworktobecarriedoutbytheAERMECservicepersonnel,allother

works(electricalandhydraulichook‐ups,primingandbleedingofair

fromthesystem)musthavebeencompleted.