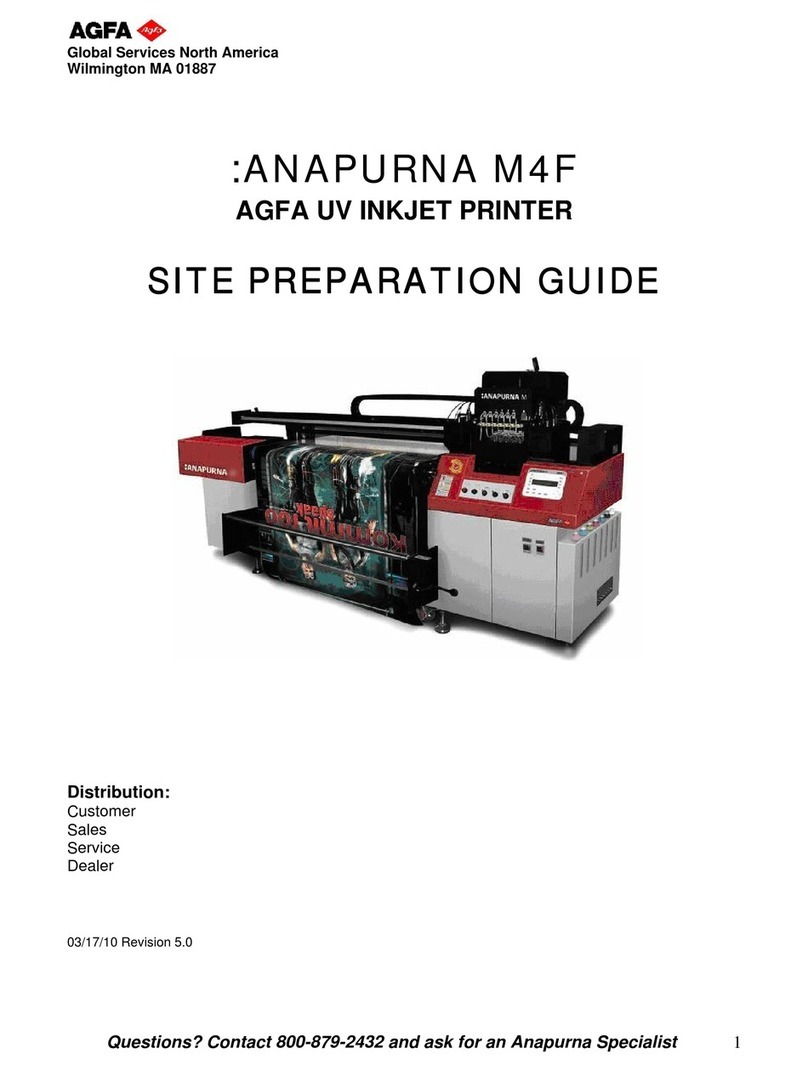

:ANAPURNA XL² OPERATOR MANUAL

AB]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]

2

]

8/08/2008

]

TABLE OF CONTENTS

1. Safety Instructions ..................................................................................................................................................................... 3

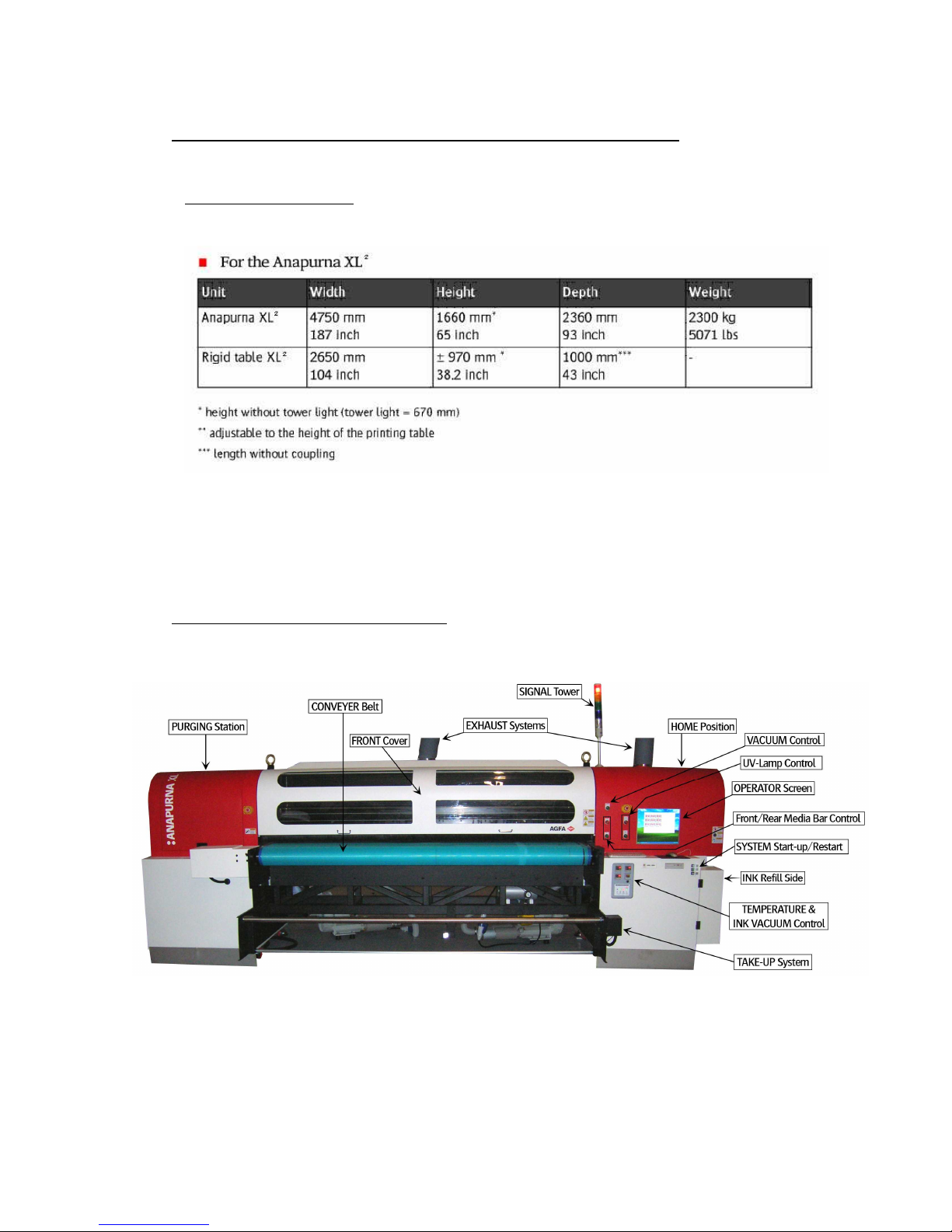

2. rinter Overview and Features ................................................................................................................................................. 4

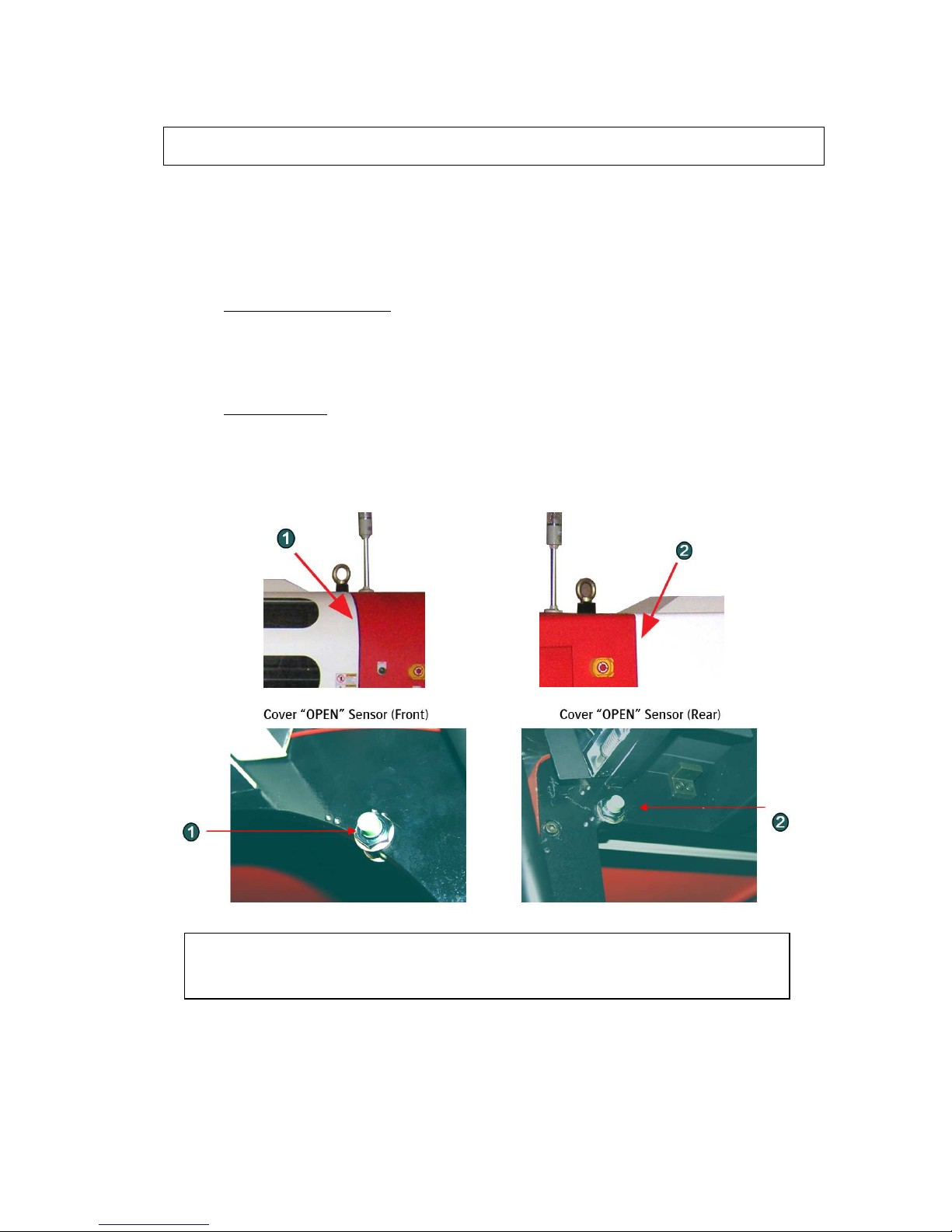

2.1 Front view, parts & locations ........................................................................................................................................ 4

2.2 Rear view, parts & locations.......................................................................................................................................... 5

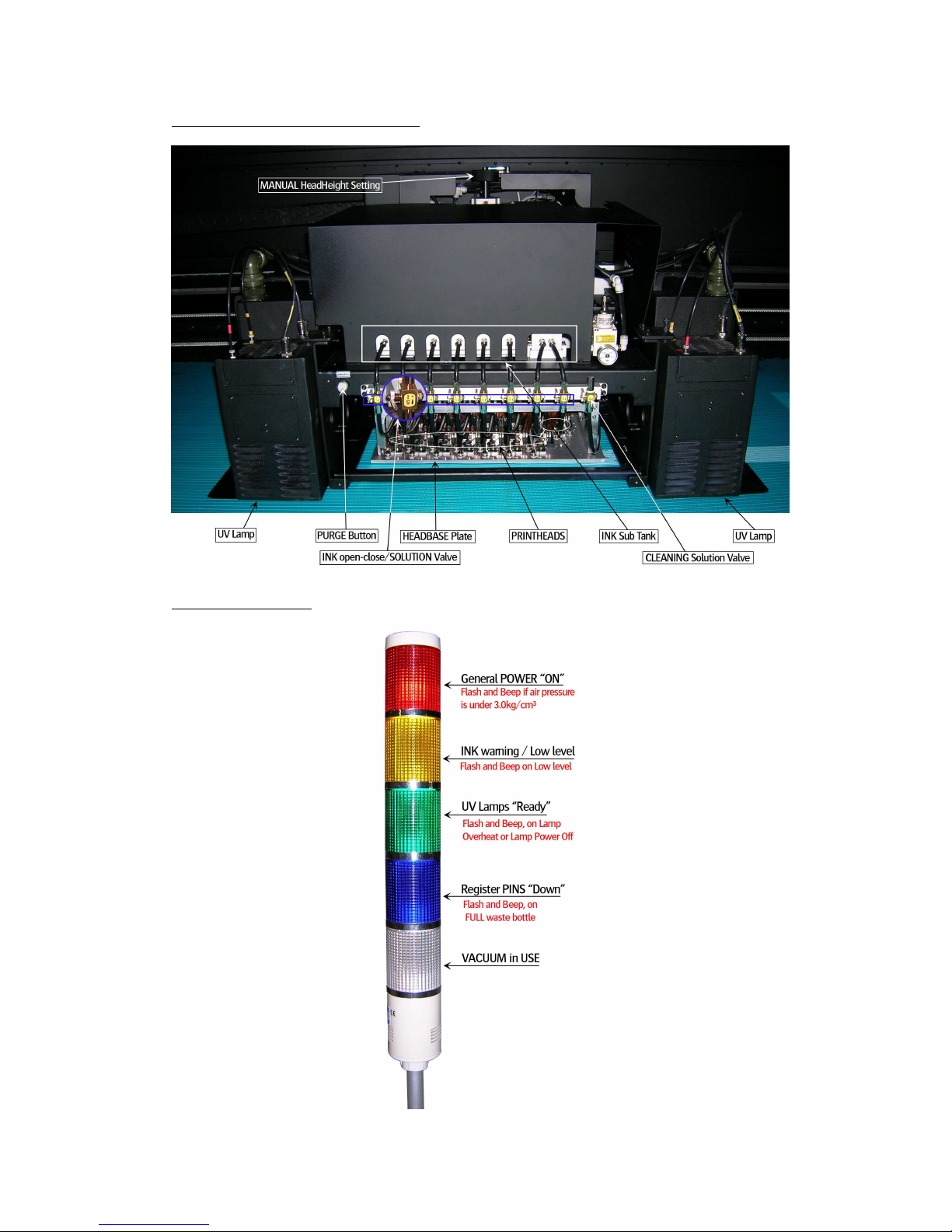

2.3 Head Carriage view, parts .............................................................................................................................................. 7

2.4 Signal tower ..................................................................................................................................................................... 7

3. Head Technology ........................................................................................................................................................................ 8

4. :Anapurna UV Curable Ink......................................................................................................................................................... 9

4.1 General information ........................................................................................................................................................ 9

4.2 Color gamut...................................................................................................................................................................... 9

4.3 acking.............................................................................................................................................................................. 9

5. Ink Circuit ................................................................................................................................................................................. 10

5.1 Main ink tanks .............................................................................................................................................................. 10

5.2 Auto ink supply............................................................................................................................................................. 10

5.3 Sub Ink Tank.................................................................................................................................................................. 11

5.4 The 2-way valves.......................................................................................................................................................... 12

5.5 Negative ressure Setting .......................................................................................................................................... 13

5.6 Waste tank..................................................................................................................................................................... 14

6. UV Curing System.................................................................................................................................................................... 15

6.1 General information ..................................................................................................................................................... 15

6.2 Curing setup and sequences ...................................................................................................................................... 15

6.3 Uni- and Bi-directional printing................................................................................................................................. 16

7. rinting Table ........................................................................................................................................................................... 17

7.1 General information ..................................................................................................................................................... 17

7.2 Belt Tension control..................................................................................................................................................... 18

7.3 Maintenance.................................................................................................................................................................. 18

7.4 Replacement ................................................................................................................................................................. 20

8. Maintenance............................................................................................................................................................................. 21

8.1 General information ..................................................................................................................................................... 21

8.2 Daily Maintenance – Nozzle check/purge .............................................................................................................. 22

8.3 Weekly Maintenance................................................................................................................................................... 25

8.4 Long Stand Still............................................................................................................................................................. 26

8.5 Bleeding air out of the ink filters .............................................................................................................................. 28

9. Media Setup ............................................................................................................................................................................. 29

9.1 Roll to Roll..................................................................................................................................................................... 29

9.1.1 Auto Feed System ............................................................................................................................................ 29

9.1.2 Take-Up control system .................................................................................................................................. 30

9.1.3 Roll Alignment.................................................................................................................................................. 30

9.1.4 Vacuum .............................................................................................................................................................. 30

9.2 Rigid Media.................................................................................................................................................................... 31

9.2.1 Rigid Support tables......................................................................................................................................... 31

9.2.2 Rigid Alignment................................................................................................................................................ 31

9.2.2.1 Media Register ins......................................................................................................................... 31

9.2.2.2 Top and Left Margin Setup............................................................................................................. 32

9.2.3 Vacuum .............................................................................................................................................................. 33

9.3 Media Tension Bars...................................................................................................................................................... 33

10. Head Base – Height Control................................................................................................................................................ 34

10.1 Automatic “Head Base Height” Setup.................................................................................................................... 34

11. :Anapurna Control rogram ................................................................................................................................................. 36

11.1 Control rogram Menu.............................................................................................................................................. 36

11.2 Setup arameter Menu ............................................................................................................................................. 37

11.3 Test Menu.................................................................................................................................................................... 46

12. rinting an image.................................................................................................................................................................. 48

12.1 reparing an image.................................................................................................................................................... 48

12.2 reparing the :Anapurna ........................................................................................................................................... 48

12.3. rinting the image .................................................................................................................................................... 49

12.4. Cancel a print............................................................................................................................................................. 50

12.5. urge function on the printing ............................................................................................................................... 50

13. Tips & Tricks........................................................................................................................................................................... 51