Key-operator mode ...................................... 53

Service mode ...............................................54

Specialist mode ............................................55

Administrator mode .....................................56

The local user interface ............................................ 57

The status indicator LED .............................. 59

The control buttons ......................................60

Audio signals ............................................... 61

The keypad .................................................. 62

The display .................................................. 64

Switching on the printer .......................................... 66

Cooling down the printer ......................................... 68

Switching off the printer ..........................................69

Basic Operation (operator mode) .........................................70

Managing the print queue ........................................71

Checking the print queue .............................71

Assigning emergency priority ...................................73

Deleting print jobs ....................................................74

Changing the film format of the trays .......................76

Loading films ...........................................................78

When the printer is printing or calculating ...79

When the printer is in the ready state ...........81

Film loading procedure ................................82

Checking the correct position of a film in the input

tray ..............................................................85

Advanced Operation (key-operator mode) ...........................86

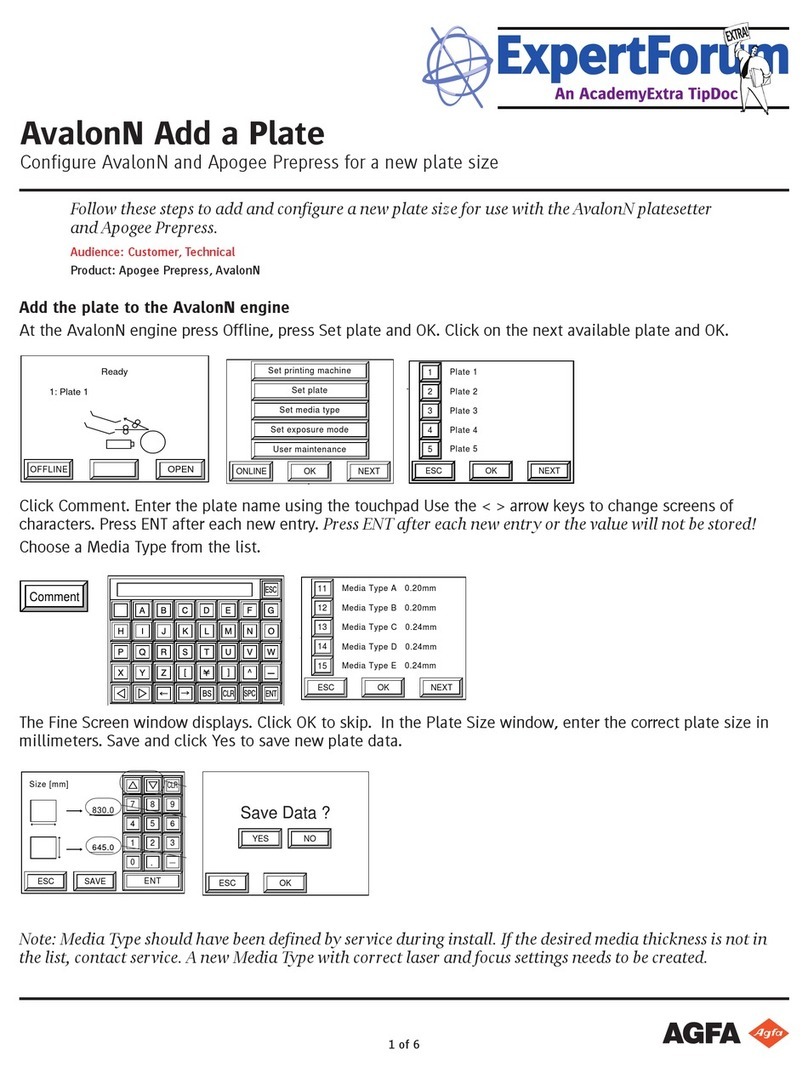

The menu structure ................................................. 87

Quality control for general radiography applications ....

88

Establishing the reference values and verifying

image quality for general radiography applications

..........................................................................89

Performing quality control (QC) tests for general

radiography applications ............................. 95

Quality control for mammography application .........99

Establishing the reference values and verifying

image quality for mammography application ...

100

Performing quality control (QC) tests for

mammography application ........................ 106

Preventive maintenance and replacements .........................110

Preventive maintenance schedule ...........................111

Safety guidelines ........................................111

Recurrent safety tests ............................................. 111

Cleaning and disinfection .......................................112

Cleaning the print head ..........................................113

Cleaning the dust rollers ........................................ 116

Cleaning the cooling air flow holes .........................119

Remarks for HF-emission and immunity ............................120

DRY 3.4 | Contents | iii

2602A EN 20191018 0826