3

2920B EN 20031206

Table of contents

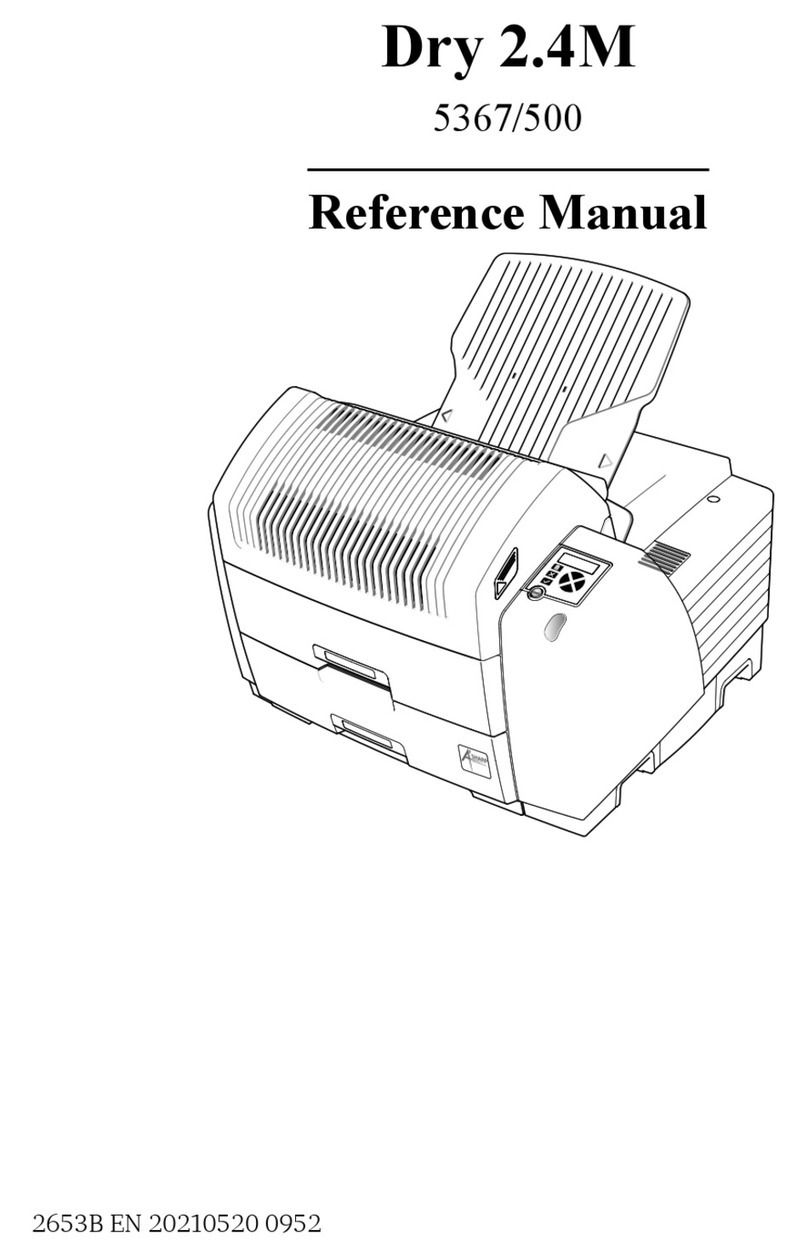

Chapter 1: Introducing the Drystar 5300..........................................................5

Drystar 5300 features.......................................................................................6

Safety precautions ...........................................................................................8

Security precautions.......................................................................................12

Safety compliance.......................................................................................... 13

Privacy and security.......................................................................................14

Operating modes ...........................................................................................16

Control modes (local and remote)...................................................................17

The user interface..........................................................................................18

Switching on the Drystar 5300........................................................................28

Switching off the Drystar 5300........................................................................30

Chapter 2: Basic operation (Operator mode).................................................31

Overview of operator functions.......................................................................32

Managing the print queue...............................................................................33

About Drystar 5300 consumables...................................................................35

Loading films..................................................................................................36

Chapter 3: Advanced operation (Key-operator mode)..................................43

Overview of key-operator functions ................................................................44

Viewing printer information............................................................................. 48

Changing the configuration settings................................................................58

Printing images..............................................................................................91

Saving the configuration settings....................................................................95

Restoring the configuration settings................................................................97

Maintaining optimal image quality.................................................................101

Service actions.............................................................................................108

Quality control procedure ............................................................................. 109

Installation operations ..................................................................................122

Chapter 4: Controlling the Drystar 5300 via a remote PC (with browser).. 139

Features ......................................................................................................140

Set up..........................................................................................................141

Setting up the connection.............................................................................142

Starting the remote session..........................................................................147

Chapter 5: System description .....................................................................149

Main components.........................................................................................150

Functional description ..................................................................................151