2 of 6

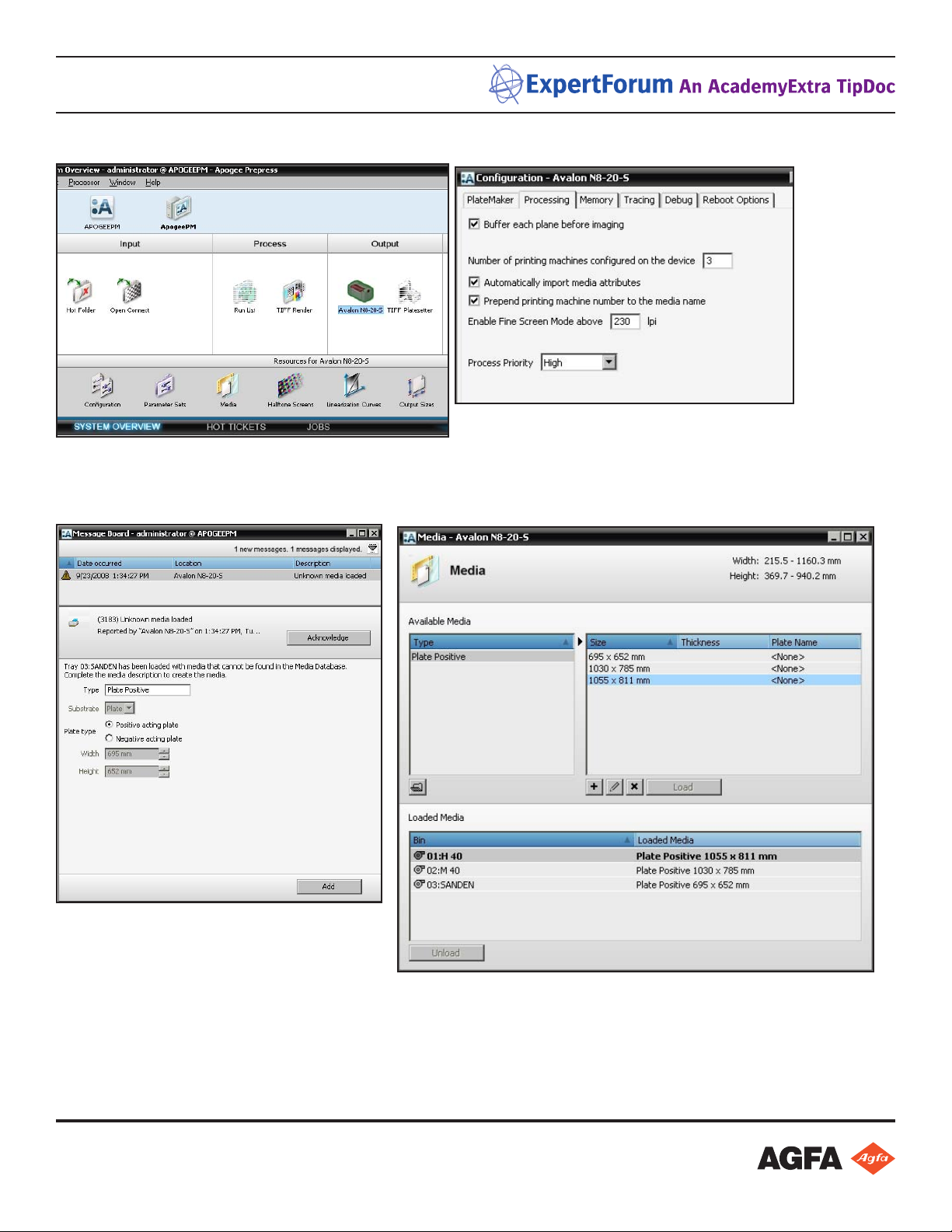

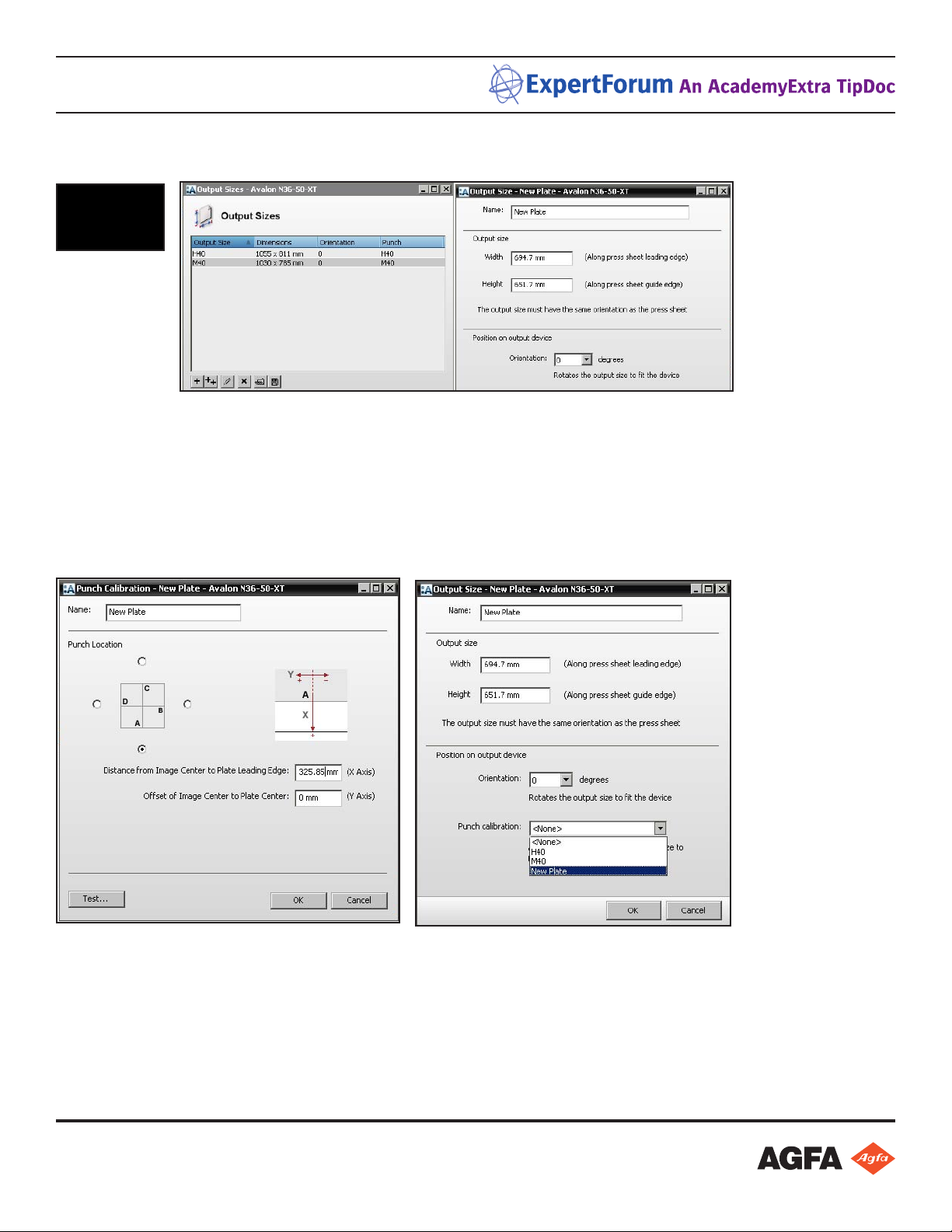

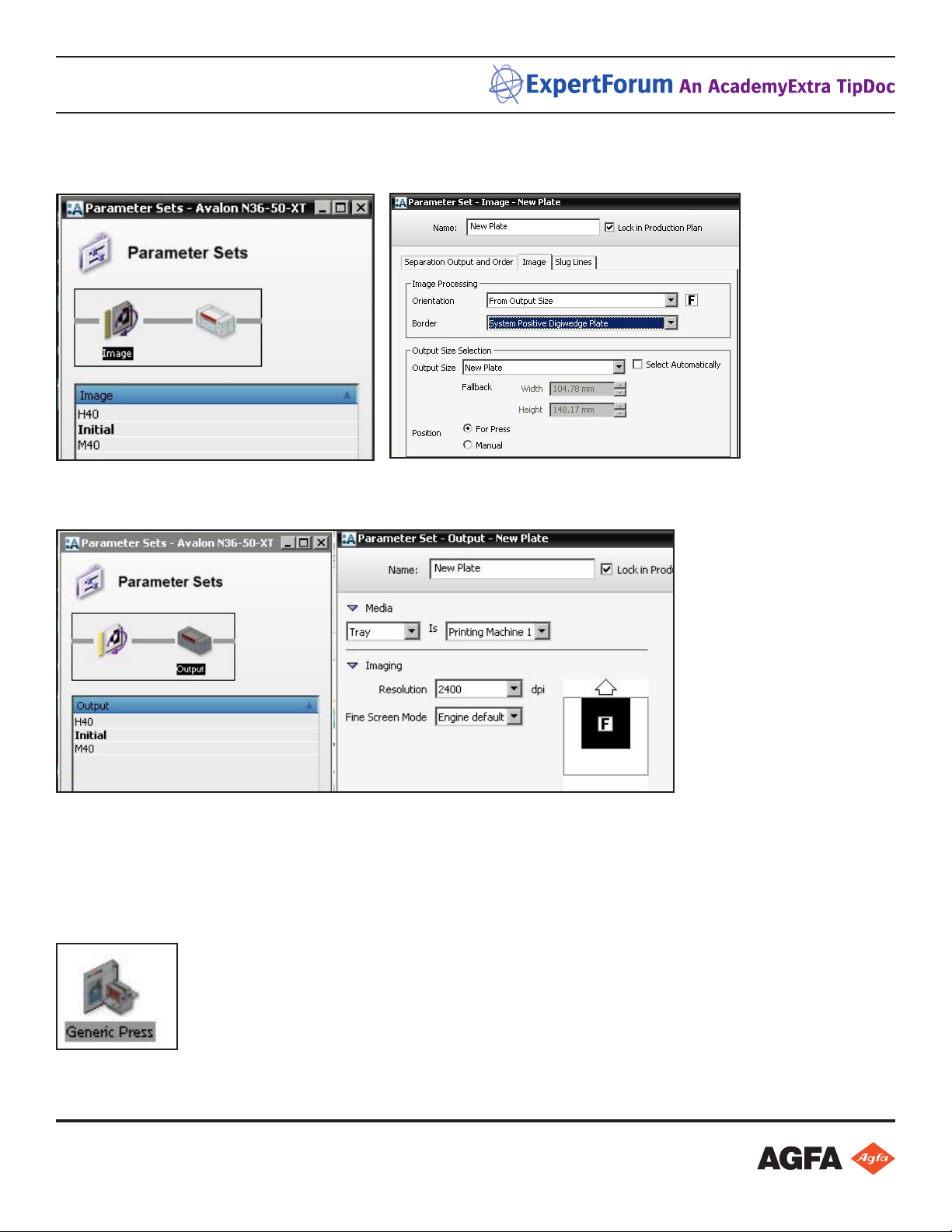

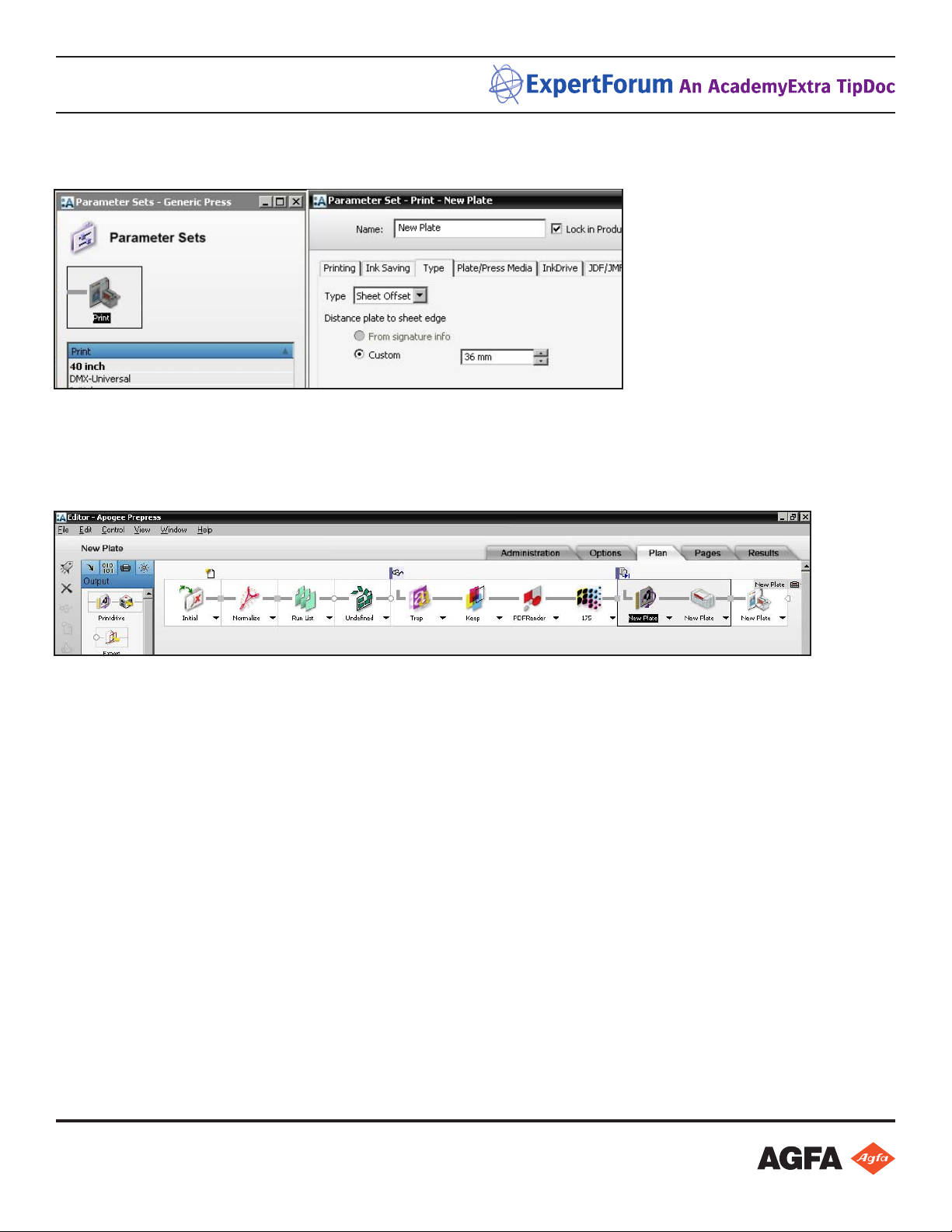

AvalonN Add a Plate

Congure Apogee Prepress for a new plate size

Add the Printing Machine to the AvalonN engine

At the main menu, press Set Printing Machine and OK. Click on the next printing machine and OK.

PT-R8300/PT-R8600 USERS MANUAL

5-2

5.1 Offline mode

5.1.1 Overview of the offline mode screen

Press [OFFLINE] in the [ONLINE] screen to display the offline screen.

The offline screen hierarchy is shown below. Press [ESC] in any of these screens to

return to the previous screen. Press [ONLINE] to return to the online screen.

User maintenance

Set exposure mode

Set media type

Set plate

OK NEXTONLINE

Set printing machine

Service

Set punch name

Information

OK NEXTONLINE

Pressing [NEXT].

Cont. on next page

5

4

3

2

OK NEXTESC

1Plate 1

Plate 2

Plate 3

Plate 4

Plate 5

5

4

3

2

OK NEXTESC

1Printing machine 1

Printing machine 2

Printing machine 3

Printing machine 4

Printing machine 5

5

4

3

2

OK NEXTESC

1Media Type 1

Media Type 2

Media Type 3

Media Type 4

Media Type 5

Select [Set printing machine] and

press [OK].

Select [Set plate] and press [OK].

Select [Set media type] and

press [OK].

PT-R8300/PT-R8600 USERS MANUAL

5-4

5.1.2 Description of buttons

The buttons available in the online screen, such as [NEXT] and [ESC], are described

below.

[NEXT]

If the displayed screen consists of multiple pages, the [NEXT] button is displayed.

Press the [NEXT] button to display the next page.

5

4

3

2

OK NEXTESC

1Printing machine 1

Printing machine 2

Printing machine 3

Printing machine 4

Printing machine 5

->

10

9

8

7

OK NEXTESC

6Printing machine 6

Printing machine 7

Printing machine 8

Printing machine 9

Printing machine 10

[ESC]

Press [ESC] to return to the previous screen (level up in the hierarchy).

[OK]Press [OK] to confirm your entry and move to the next screen.

[Comment]

Press [Comment] to display the keyboard screen. Enter a comment into the icon for

the keyboard window and press [ENT]. The previous screen appears and the com-

ment inputted will be displayed under the [Comment] button.

:Switch through the entry

screens for upper case

letters, lower case letters, and

symbols/numbers.

:Move the cursor indicating the

entry position.

BS

: Delete the letter to the left of the

cursor.

CLR

: Clear the entered comment.

SPC

: Enter a space.

OK

Comment

Plate

Copy from

ESC

Printing machine 1

Plate 1

Comment

PT-R8300/PT-R8600 USERS MANUAL

5-4

5.1.2 Description of buttons

The buttons available in the online screen, such as [NEXT] and [ESC], are described

below.

[NEXT]

If the displayed screen consists of multiple pages, the [NEXT] button is displayed.

Press the [NEXT] button to display the next page.

5

4

3

2

OK NEXTESC

1Printing machine 1

Printing machine 2

Printing machine 3

Printing machine 4

Printing machine 5

->

10

9

8

7

OK NEXTESC

6Printing machine 6

Printing machine 7

Printing machine 8

Printing machine 9

Printing machine 10

[ESC]

Press [ESC] to return to the previous screen (level up in the hierarchy).

[OK]Press [OK] to confirm your entry and move to the next screen.

[Comment]

Press [Comment] to display the keyboard screen. Enter a comment into the icon for

the keyboard window and press [ENT]. The previous screen appears and the com-

ment inputted will be displayed under the [Comment] button.

:Switch through the entry

screens for upper case

letters, lower case letters, and

symbols/numbers.

:Move the cursor indicating the

entry position.

BS

: Delete the letter to the left of the

cursor.

CLR

: Clear the entered comment.

SPC

: Enter a space.

OK

Comment

Plate

Copy from

ESC

Printing machine 1

Plate 1

Comment

PT-R8300/PT-R8600 USERS MANUAL

5-4

5.1.2 Description of buttons

The buttons available in the online screen, such as [NEXT] and [ESC], are described

below.

[NEXT]

If the displayed screen consists of multiple pages, the [NEXT] button is displayed.

Press the [NEXT] button to display the next page.

5

4

3

2

OK NEXTESC

1Printing machine 1

Printing machine 2

Printing machine 3

Printing machine 4

Printing machine 5

->

10

9

8

7

OK NEXTESC

6Printing machine 6

Printing machine 7

Printing machine 8

Printing machine 9

Printing machine 10

[ESC]

Press [ESC] to return to the previous screen (level up in the hierarchy).

[OK]Press [OK] to confirm your entry and move to the next screen.

[Comment]

Press [Comment] to display the keyboard screen. Enter a comment into the icon for

the keyboard window and press [ENT]. The previous screen appears and the com-

ment inputted will be displayed under the [Comment] button.

:Switch through the entry

screens for upper case

letters, lower case letters, and

symbols/numbers.

:Move the cursor indicating the

entry position.

BS

: Delete the letter to the left of the

cursor.

CLR

: Clear the entered comment.

SPC

: Enter a space.

OK

Comment

Plate

Copy from

ESC

Printing machine 1

Plate 1

Comment

Click Comment. Enter the printing machine name using the touchpad. Use the < > arrow keys to change

screens of characters. Press ENT after each new entry. Choose the Plate dened before. OK past Fine Screen.

PT-R8300/PT-R8600 USERS MANUAL

5-2

5.1 Offline mode

5.1.1 Overview of the offline mode screen

Press [OFFLINE] in the [ONLINE] screen to display the offline screen.

The offline screen hierarchy is shown below. Press [ESC] in any of these screens to

return to the previous screen. Press [ONLINE] to return to the online screen.

User maintenance

Set exposure mode

Set media type

Set plate

OK NEXTONLINE

Set printing machine

Service

Set punch name

Information

OK NEXTONLINE

Pressing [NEXT].

Cont. on next page

5

4

3

2

OK NEXTESC

1Plate 1

Plate 2

Plate 3

Plate 4

Plate 5

5

4

3

2

OK NEXTESC

1Printing machine 1

Printing machine 2

Printing machine 3

Printing machine 4

Printing machine 5

5

4

3

2

OK NEXTESC

1Media Type 1

Media Type 2

Media Type 3

Media Type 4

Media Type 5

Select [Set printing machine] and

press [OK].

Select [Set plate] and press [OK].

Select [Set media type] and

press [OK].

PT-R8300/PT-R8600 USERS MANUAL

5-8

5.2.3 Grip direction and leading/trailing gripper settings

Set the plate grip direction and the length of the leading and trailing grip amount

(amount of offset from the edge of the plate to the printed area).

OKESC

Spiral/Step

Grip direction

:Select horizontal gripping (at the top and bottom) of the plate.

: Select vertical gripping (at each side) of the plate.

1)Select the grip direction and then press [OK]. The following screen appears.

Vertical grip screen Horizontal grip screen

NOTE

• The leading/trailing grip position changes depending on the grip direction set in Step 1.

2)Enter the leading grip margin and then press [ENT]. The highlight will move to the

trailing grip margin setting.

3)Enter the trailing grip margin and then press [ENT].

4)After input is complete, press [OK].

(Cont. on “5.2.4 Setting the image centering method”)

ESC

Grip [

OKESC

Grip [mm]/

After Grip

0.0 mm

0.0 mm

CLR

7 8 9

4 5 6

1 2 3

0

ENT

These keys also move

the highlight.

Leading grip margin

Trailing grip margin

5-9

Chapter 5 User menu

5.2.4 Setting the image centering method

The image centering function is used to center the image data in the center of the

print area minus the leading and trailing grip margins. (The following screen illustra-

tion assumes that the grip direction has been set to horizontal gripping.)

OKESC

Centering

Primary scanning direction (vertical) :centering OFF

Secondary scanning direction (horizontal) :centering ON

Primary scanning direction (vertical) :centering ON

Secondary scanning direction (horizontal) :centering ON

Primary scanning direction (vertical) :centering OFF

Secondary scanning direction (horizontal) :centering OFF

Primary scanning direction (vertical) :centering ON

Secondary scanning direction (horizontal) :centering OFF

Select the centering method and then press [OK].

(Cont. on “5.2.5 Setting the image offset”)

()

()

()

()

Enter the Grip direction and OK, then enter the Grip and After Grip in mm and ok.

Any Grip/After Grip must be subtracted from the Output Size in Apogee Prepress. Zero is recommended and

gives you the most exibility for placing borders from Apogee Prepress.

Press ENT after each entry. Select the rst centering option (center across media, push to bottom). OK past

offsets to get to the Punch dialog.

PT-R8300/PT-R8600 USERS MANUAL

5-12

5.2.6 Punch

Set the punch type and hook punch.

OKESC

Hook punch

OFF

Punch

ON

Plate positioning Home

1)Setting the punch

Press [Punch]. The following screen appears.

NOTE

• If [OFF] is selected, the plate will not be punched.

2)Select the desired punch type from the registered punch types and then press

[OK]. The punch type will be linked to printing machine 1, and you will return to

the punch setting screen.

NOTE

• For the procedure for registering punch types, refer to “5.8 Setting the punch name.”

3)Setting the hook punch

Select whether or not the hook punch should punch. This selection will determine

the effective exposure area and drum rotation speed.

PT-R8300/PT-R8600 USERS MANUAL

5-12

5.2.6 Punch

Set the punch type and hook punch.

OKESC

Hook punch

OFF

Punch

ON

Plate positioning Home

1)Setting the punch

Press [Punch]. The following screen appears.

NOTE

• If [OFF] is selected, the plate will not be punched.

2)Select the desired punch type from the registered punch types and then press

[OK]. The punch type will be linked to printing machine 1, and you will return to

the punch setting screen.

NOTE

• For the procedure for registering punch types, refer to “5.8 Setting the punch name.”

3)Setting the hook punch

Select whether or not the hook punch should punch. This selection will determine

the effective exposure area and drum rotation speed.

5-15

Chapter 5 User menu

5.2.8 Fine adjustment of the image position

Perform fine adjustment (shifting the print area) of the image output position on the

plate.

These keys also move the highlight.

Shift amount in the secondary

scanning (horizontal) direction

Shift amount in the primary

scanning (vertical) direction

1)Enter the desired shift in the secondary scanning (horizontal) direction and then

press [ENT]. The highlight will move to the shift setting in the primary scanning

direction.

2)Enter the desired shift amount in the primary scanning (vertical) direction and

then press [ENT].

3)After input is complete, press [SAVE]. The save confirmation screen appears.

OK

YES NO

ESC

Save Data ?

4)Press [YES] and then [OK] to save all the information you set as printing machine

1 data. The data is saved and the screen returns to the first screen in “5.3 Set

plate”.

SAVEESC

Paper Position H

Paper Position V

0.0 mm

0.0 mm

R

R

CLR

7 8 9

4 5 6

1 2 3

0

ENT

The Hook Punch registers the plate in the AvalonN and is usually turned On (unless setback is less that

12mm). An optional plate punch can be selected if installed and available. Skip past the ne adjustment

screens and choose Yes to save the data. Put the AvalonN back online.

If a new plate punch is purchased it needs to be installed and congured by Agfa Service.