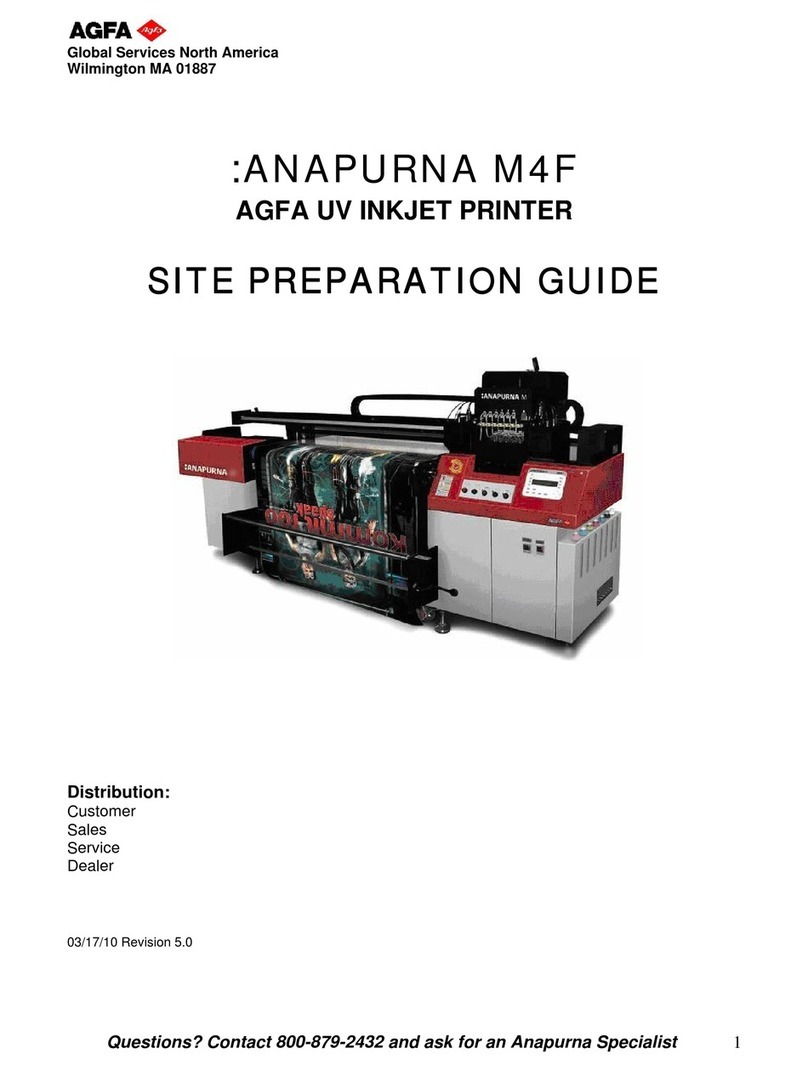

Stay ahead. With Agfa Global Services. :Anapurna M4F - Operator Manual

Index 3

Index

A. INFORMATION.

1. Safety instructions. .............................................................................................................. 5

1.1 Warning labels............................................................................................................ 5

1.2 Emergency switches. ................................................................................................. 6

1.3 Optical safety sensors. .............................................................................................. 6

1.4 U.V. light....................................................................................................................... 7

a. Detail of the UV light......................................................................................... 7

1.5 U.V. inks........................................................................................................................ 8

a. Curing Process..................................................................................................... 8

1.6 Extra information........................................................................................................ 8

2. Printer overview.................................................................................................................... 9

2.1 Front view, parts & locations. .................................................................................. 9

2.2 Home view, parts & locations.................................................................................. 9

2.3 Capping station view, parts & locations.............................................................. 10

2.4 Head carriage view, parts & locations.................................................................. 10

2.5 Rearside view, parts & locations........................................................................... 10

B. OPERATIONS.

1. Makingyourrstprint....................................................................................................... 11

1.1 Wasatch SoftRIP: setting up your image............................................................. 11

1.2 Starting up the :Anapurna M4F.............................................................................. 11

1.3 Makingyourrstprint............................................................................................. 12

2. The Wasatch SoftRIP 6.4 AE............................................................................................. 13

2.1 Main Window - overview........................................................................................ 13

a. Menu items........................................................................................................ 13

b. Universal Controls. ........................................................................................... 14

c. Top tabs............................................................................................................... 14

d. Left tabs.............................................................................................................. 14

2.2 Open an image.......................................................................................................... 15

2.3 Cropping, resizing an image................................................................................... 15

a. Resizing. ............................................................................................................. 15

b. Cropping. ............................................................................................................ 15

c. Restore Original View. ..................................................................................... 16

d. Rotating. ............................................................................................................. 16

e. Mirroring. ............................................................................................................ 17

2.4 Choosinganimagingconguration...................................................................... 17

2.5 Ripping and printing the image............................................................................. 17

3. The operator panel. (general overview) ......................................................................... 19

4. Start up & Shutdown Procedures. ................................................................................... 20

4.1 Start up Procedure ................................................................................................... 20

4.2 Making the engine ready for Printing. ................................................................. 20

4.3 Shutdown Procedures.............................................................................................. 21

a. Dialy Shut Down Procedure............................................................................ 21

b. Weekly Shut Down Procedure........................................................................ 21

c. Long Stand Still Shut Down Procedure (More than 14 days) ................... 21

5. Setting up the :Anapurna M4F. (the calibration menu)............................................... 23

5.1 Feed Adjust (F1)........................................................................................................ 23

5.2 Carriage Release (F2). .............................................................................................. 23

5.3 Factory setting (F3). ................................................................................................. 23

5.4 Hori. Adjust (F4). ....................................................................................................... 23

5.5 Dir. Adjust (F4)........................................................................................................... 24

5.6 Head Gap (F6). ........................................................................................................... 24

5.7 Importance of the bi-directional alignment........................................................ 26

6. Changing the parameters. (the main menu).................................................................. 28

6.1 Information bar. ........................................................................................................ 28

6.2 Function keys (parameters). ................................................................................... 29

6.3 Media setup. (rigids and roll to roll) ..................................................................... 33

a. Rigid media........................................................................................................ 33

b. Roll media. ......................................................................................................... 34

c. Vacuum system................................................................................................. 36