Installation Instructions

Original Instructions

Bulletin 800G Assembled Stations

Catalog Numbers

800G-1

x

-EX, 800G-2x-EX, 800G-3x-EX

Product Description

There are many variations and configurations available for assembled

station solutions. All assembled station configurations use a one-hole

(800G-1x-EX), two-hole (800G-2x-EX), or three-hole (800G-3x-EX)

enclosure with various front-of-panel operators and back-of-panel

components.

Up to three enclosures of any size can be ganged together in a vertical

arrangement, allowing a combined assembled station to have up to nine

operators (three enclosures with each enclosure containing three

operators). Assembled stations have various conduit-entry

configurations using plastic or metal cable glands, along with many

different accessories such as locking covers, locking guards, and custom

legend plates. Assembled stations must be ordered directly from

Rockwell Automation to maintain compliance with hazardous

location standards and certifications; field assembly is not permitted.

Safety Instructions

Improper installation can cause malfunctioning and the loss of

explosion protection.

All assembled stations can only be used within the specified ambient

temperature range (depending on the voltage, current, and hazardous

area classification).

ATTENTION: To help prevent electrical shock, disconnect from

power source before installing or servicing. Follow NFPA 70E

requirements. Install in suitable enclosure. Keep free from

contaminants.

Only suitably trained personnel can install, adjust, commission,

use, assemble, disassemble, and maintain the product in

accordance with applicable code of practice. If a malfunction or

damage occurs, do not attempt to repair the product.

IMPORTANT When working in hazardous areas, thesafety of personnel

and equipment depends on compliance with the relevant

safety regulations. The people in charge of installation and

maintenance bear a special responsibility. They must be

knowledgeable of the applicable rules andregulations.

These instructions provide a summary of the most important

installation measures. Everyone working with the product

mustreadtheseinstructionsso that theyarefamiliarwiththe

correct handling of the product.

Keep these instructions for future reference as they must be

available throughout the expected life of the product.

Assembled Stations

Certifications

ATEX CML 15 ATEX 3024

IECEx IECEx CML 15.0014

NEPSI GYJ17.1200X

INMETRO UL-BR 17.0366

Gas Protection Type II 2 G Ex db eb IIC T6 Gb

Dust Protection Type II 2 D Ex tb IIIC T80°C Db

Mechanical and Electrical Ratings

Zone Rating Zone 1, Zone 2, Zone 21, Zone 22

Ambient Temperature Range -55…+60 °C (-67…+140 °F)

Degree of Protection IP64/IP66

Enclosure Material Thermoplastic

Enclosure Sizes One-hole, two-hole, or three-hole

Ganged Enclosures Up to three enclosures

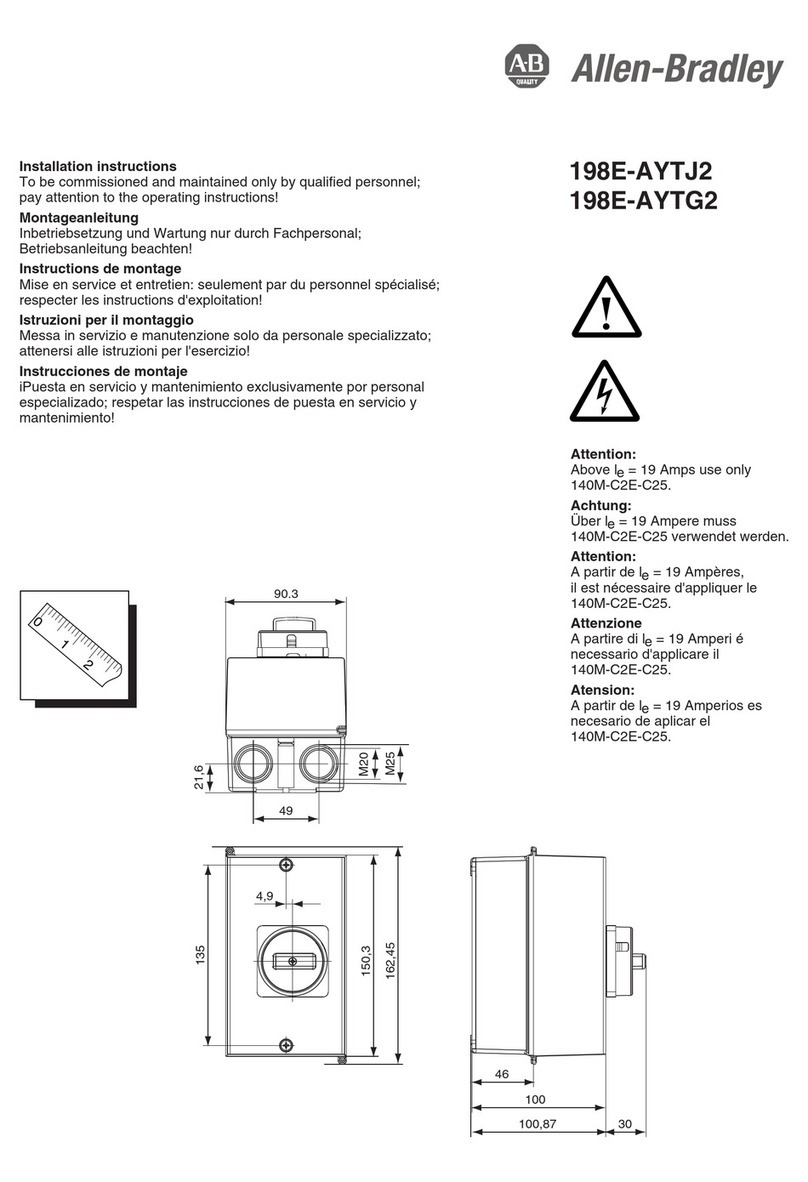

Cable Gland Clamping Range

Plastic M20/Plastic M20x2 Cable Ø7…13 mm (9/32…33/64 in.)

Plastic M25 Cable Ø12…17 mm (15/32…43/64 in.)

Metal M20 Cable Ø8.5…14.5 mm (21/64… 37/64 in.)

Metal M25 Cable Ø12…20 mm (15/32…25/32 in.)

Metal M20x2 Cable Ø6…12 mm (15/64…15/32 in.)

Metal Cable Gland Armor™ WireSize

Metal M20 Armor wire Ø0.8…1.3 mm (1/32…3/64 in.)

Metal M25 Armor wire Ø1.0…1.6 mm (3/64…1/16 in.)

Metal M20 x 2 Armor wire Ø0.7…1.2 mm (1/32…3/64 in.)

Contact Block Components

Rated Insulation Voltage, Max 690V AC

Rated Voltage (Ue) AC 250V and 400V; DC 24V and 110V

Utilization Category (AC) AC-12: 16 A, 400V, AC-15: 10 A, 400V

Utilization Category (DC) DC-13: 1 A, 24V, DC-13: 0.5 A, 110V

Conventional Thermal Current (Ithe)16 A / 40 °C (104 °F)

11 A / 60 °C (140 °F)

Contact Options 1 N.O./1 N.C., 2 N.O., 2 N.C.

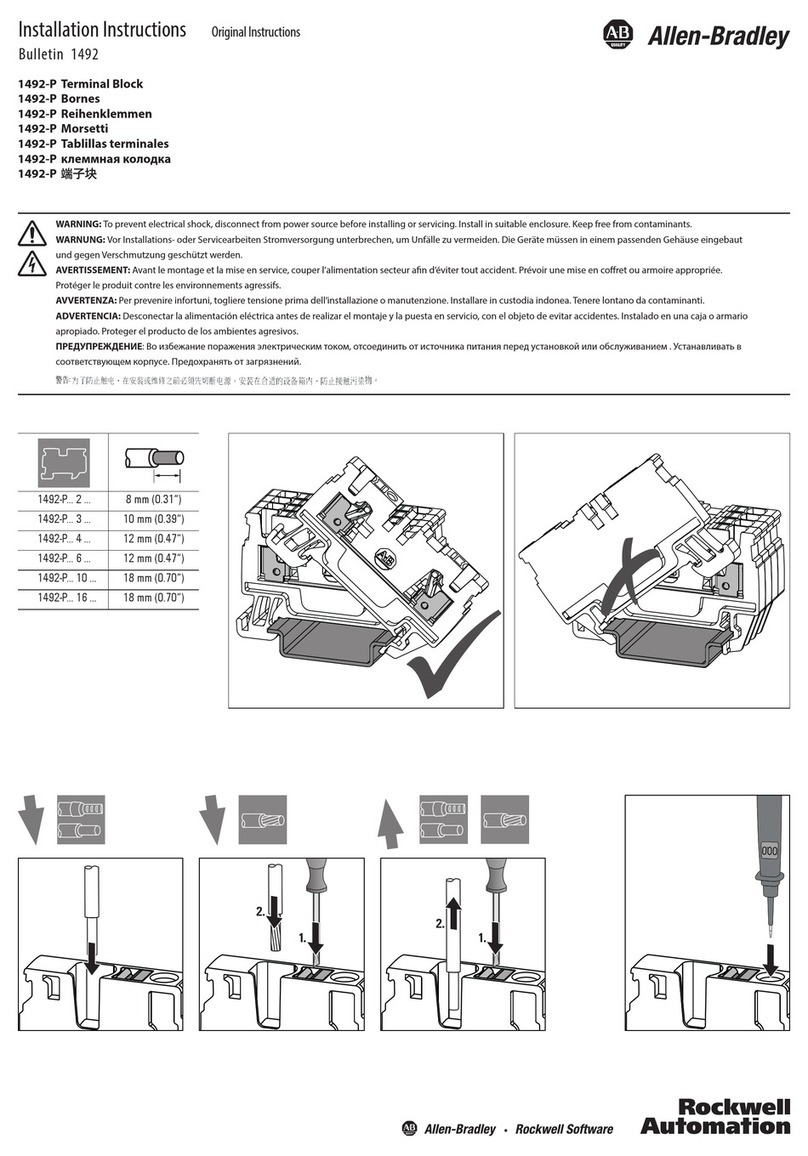

Wire/Cable Size 0.75…2.5 mm² (18…14 AWG)

Power Module Components

Rated Insulation Voltage 300V

Power Consumption ≤ 1 W

Rated Voltage (Ue) Ta< 50 °C (122 °F) 12…250V AC, 12…60V DC

Rated Voltage (Ue) Ta< 60 °C (140 °F) 12…24V AC/DC

Wire/Cable Size 0.75…2.5 mm² (18…14 AWG)

Power Module with Contact Block Components

Rated Insulation Voltage 300V

Power Consumption ≤1 W

Rated Voltage (Ue) Ta< 50 °C (122 °F) 12…250V AC, 12…60V DC

Rated Voltage (Ue) Ta< 60 °C (140 °F) 12…24V AC/DC

Contact Options 1 N.O., 1 N.C.

Utilization Category (AC) AC-15: 1 A, 230V

Utilization Category (DC) DC-13: 0.25 A, 24V

Wire/Cable Size 0.75…2.5 mm² (18…14 AWG)

Assembled Stations