Alliance Laundry Systems LES33A F4562 Series User manual

Other Alliance Laundry Systems Dryer manuals

Alliance Laundry Systems

Alliance Laundry Systems 70444901R3 Owner's manual

Alliance Laundry Systems

Alliance Laundry Systems CHD25G2-CA025L Owner's manual

Alliance Laundry Systems

Alliance Laundry Systems DR3003WX User manual

Alliance Laundry Systems

Alliance Laundry Systems JE2870 User manual

Alliance Laundry Systems

Alliance Laundry Systems BA120L User manual

Alliance Laundry Systems

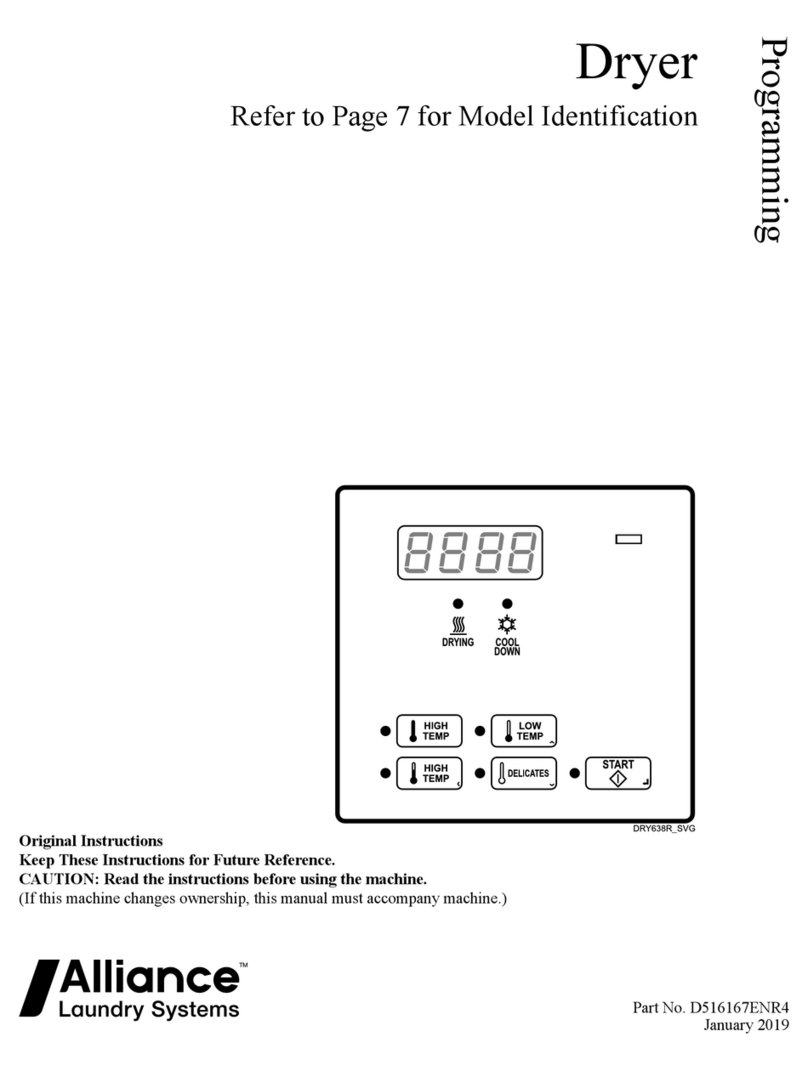

Alliance Laundry Systems DRY684C Guide

Alliance Laundry Systems

Alliance Laundry Systems SFE107*A User manual

Alliance Laundry Systems

Alliance Laundry Systems CHD25G2-CA025L Owner's manual

Alliance Laundry Systems

Alliance Laundry Systems AT120FG User manual

Alliance Laundry Systems

Alliance Laundry Systems LTS97A*N User manual

Alliance Laundry Systems

Alliance Laundry Systems LES33 User manual

Alliance Laundry Systems

Alliance Laundry Systems ATB50CG Operating instructions

Alliance Laundry Systems

Alliance Laundry Systems 800795 User manual

Alliance Laundry Systems

Alliance Laundry Systems LGS19A-1188 User manual

Alliance Laundry Systems

Alliance Laundry Systems HAT30N Operating instructions

Alliance Laundry Systems

Alliance Laundry Systems Drying Tumblers none User manual

Alliance Laundry Systems

Alliance Laundry Systems BDEBCAGS173TN01 User manual

Alliance Laundry Systems

Alliance Laundry Systems Drying Cabinet User manual

Alliance Laundry Systems

Alliance Laundry Systems DCB30CG User manual

Alliance Laundry Systems

Alliance Laundry Systems Speed Queen DF7000WG User manual

Popular Dryer manuals by other brands

Asko

Asko T793C operating instructions

Kenmore

Kenmore 8041 - 5.8 cu. Ft. Capacity Electric Dryer installation instructions

Frigidaire

Frigidaire CAQE7077KW0 use & care

Bosch

Bosch WTX8HKM9SN User manual and installation instructions

Sharp

Sharp KD-NHH9S7GW2-PL user manual

Samsung

Samsung DV431AEPXAC user manual