ARB 3500720 User manual

Last Rev Date:

2

5

/0

6

/1

9

Page

1

of

1

4

Fitting instructions# 378

93

37

Copyright © 2019 by ARB Corporation Limited. All rights reserved, this document must not be reproduced without the express authority of ARB Corporation Ltd

Part Number:

3500720

, 3501000

Product

Description:

SUMMIT BAR

WINCH INSTALL KIT

Refer to Bull Bar fitting instructions for winch compatibility.

Winches may require additional fitting kits. Refer to table below for details.

WINCH MODEL

ADDITIONAL KITS

Zeon 8: W89965 WARN ZEON EXTENDED CABLE KIT

Zeon 8s: W89965 WARN ZEON EXTENDED CABLE KIT & 3500600 HAWSE FAIRLEAD ADAPTER KIT

Zeon 10: W89965 WARN ZEON EXTENDED CABLE KIT

Zeon 10s

Zeon 12:

W89965 WARN ZEON EXTENDED CABLE KIT & 3500600 HAWSE FAIRLEAD ADAPTER KIT

W89965 WARN ZEON EXTENDED CABLE KIT

Zeon 10 Platinum: W89965 WARN ZEON EXTENDED CABLE KIT

Zeon 10-s Platinum:

Zeon 12 Platinum:

W89965 WARN ZEON EXTENDED CABLE KIT & 3500600 HAWSE FAIRLEAD ADAPTER KIT

W89965 WARN ZEON EXTENDED CABLE KIT

XP: -

XPs: 3500600 HAWSE FAIRLEAD ADAPTER KIT

M8000: -

M8000s: 3500600 HAWSE FAIRLEAD ADAPTER KIT

XD9: -

XD9s: 3500600 HAWSE FAIRLEAD ADAPTER KIT

9.5XDC: 3500410 WARN XDC ADAPTER KIT

9.5XDC-s: 3500600 HAWSE FAIRLEAD ADAPTER KIT & 3500410 WARN XDC ADAPTER KIT

Magnum 8: -

Magnum 8s: 3500600 HAWSE FAIRLEAD ADAPTER KIT

Magnum 10:

-

Magnum 10s:

Magnum 12:

3500600

HAWSE FAIRLEAD ADAPTER KIT

-

Bushranger DV9TH: 3500780 BUSHRANGER CABLE COVER KIT

(OPTIONAL)

Bushranger Seal 9.5TH:

Bushranger DV12TH:

3500600 HAWSE FAIRLEAD ADAPTER KIT & 3500780 BUSHRANGER CABLE COVER KIT

(OPTIONAL)

3500780 BUSHRANGER CABLE COVER KIT (OPTIONAL)

Bushranger REVO 10W:

-

Bushranger REVO 10S: 3500600 HAWSE FAIRLEAD ADAPTER KIT

Smittybilt X20 10lbs cable: 3500770 SMITTYBILT ADAPTER KIT

Smittybilt X20 10lbs rope : 3500600 HAWSE FAIRLEAD ADAPTER KIT and 3500770 SMITTYBILT ADAPTER KIT

ARB 4x4 ACCESSORIES

Corporate Head Office

42-44 Garden St Tel: +61 (3) 9761 6622

Kilsyth, Victoria Fax: +61 (3) 9761 6807

AUSTRALIA 3137

www.arb.com.au

Last Rev Date:

2

5

/0

6

/1

9

Page

2

of

1

4

Fitting instructions# 378

93

37

Copyright © 2019 by ARB Corporation Limited. All rights reserved, this document must not be reproduced without the express authority of ARB Corporation Ltd

FITTING REQUIREMENTS

HAVE AVAILABLE THESE SAFETY ITEMS WHEN FITTING PRODUCT:

Protective eyewear

Hearing protection

NOTE: ‘WARNING’ notes in the fitting procedure relate to OHS situations, where to avoid a

potentially hazardous situation it is suggested that protective safety gear be worn or a safe work

procedure be employed. If these notes and warnings are not heeded, injury may result.

FASTENER TORQUE SETTINGS:

SIZE

Torque Nm

Torque lbft

M6 9Nm 7lbft

M8 22Nm 16lbft

M10 44Nm 32lbft

M12 77Nm 57lbft

Last Rev Date:

2

5

/0

6

/1

9

Page

3

of

1

4

Fitting instructions# 378

93

37

Copyright © 2019 by ARB Corporation Limited. All rights reserved, this document must not be reproduced without the express authority of ARB Corporation Ltd

PARTS LISTING

ITEM NO.

PART

NUMBER DESCRIPTION QTY.

1 3194775 PLATE CABLE GUARD SUMMIT BARS 1

2 3759464 NUMBER PLATE BRACKET LIFT UP 1

3 3759465 NUMBER PLATE BRACKET MOUNT 1

4 3759658 WARN CONTROL BOX BRACKET SUMMIT BARS 1

5 4581287 WASHER SPRING M6 x 2.5 x 1.6 BLACK ZINC 4

6 4584295 WASHER FLAT M6 X 12 X 1.3 BLACK ZINC 8

7 5848302 PACKER NYLON 2

8 6151074 BOLT UNC 3/8 X 1 ¾ 2

9 6151213 BOLT M6 x 1.0 x 20 8.8 BLACK ZINC 2

10 6151223 NUT NYLOC M6 x 1.0 BLACK ZINC 2

11 6151384 SCREW 5.2 X 16 BLACK ZINC 4

12 6151456 BOLT M10 x 1.5 x 45 ZINC 2

13 6151550 BOLT M6 x 1.0 x 25 PC8.8 BLACK ZINC 4

14 6151561 NUT FLANGE M6 x 1.0 BLACK ZINC 4

15 6250010 SPACER 17 X 12.6 X 10 4

16 6821189 NUMBER PLATE GROMMET 4

17 3789337 F/INST 3500720 3501000 WINCH INSTALL KIT SUMMIT

BAR (THIS DOCUMENT) 1

Last Rev Date:

2

5

/0

6

/1

9

Page

4

of

1

4

Fitting instructions# 378

93

37

Copyright © 2019 by ARB Corporation Limited. All rights reserved, this document must not be reproduced without the express authority of ARB Corporation Ltd

WINCH PREPA

RATION

This ARB bar has been designed to carry a variety of Warn, Magnum, Smittybilt and Bushranger

winches. Before the winch is fitted into the bar it will need to be configured for proper fit and operation.

Note: Before fitting the winch to the bar, ensure that you have read and understand the fitting

instructions supplied with the winch. These instructions only cover the fitment of the winch and

control box to the bar. They do not cover the wiring procedure. For this refer to the winch

manufacturer’s instructions.

You will need to modify your winch to allow fitment into the bar. See below for each of the winch brands:

Note: The pictures below show the winches following modification.

Warn / Magnum / Smittybilt winches: Undo the

screws in the gearbox end of the winch. Carefully

slide the gearbox away from the winch only until it

is able to rotate. Rotate the gear box anti-clockwise

72° and replace screws.

Smittybilt winches only. Motor will need to be

rotated for adequate cable length. Remove 4 motor

retaining bolts and cover. Remove 2 additional

motor cap bolts. Rotate the motor until electrical

connections are facing upwards. Reinstall retaining

bolts and motor cover. (SMITTYBILT “GEN 2”

shown)

Ensure drain holes are correctly orientated. Refer

to winch instructions for more details.

Warn Zeon winches*: Undo the screws in the

gearbox end of the winch. Carefully slide the

gearbox away from the winch only until it is able to

rotate. Rotate the gear box anti-clockwise 72° and

replace screws.

Remove the control box as per the Zeon control

pack relocation kit installation guide.

Install the Warn Zeon relocation kit to the

winch and control box.

*Not required for Zeon Platinum models.

Bushranger winches: Undo the screws in the

gearbox end of the winch to remove the brake

cover. Remove the bolts retaining the gearbox

housing.

Rotate the gearbox anti-clockwise until the clutch is

as close as possible to directly upwards. Gearbox

rotation increments may be 36 °, 40° or 90°

depending on model. (“REVO 10” model shown)

Ensure fine seals are seated correctly then replate

and tighten all fasteners.

Ensure drain holes are correctly orientated

Refer to winch instructions for more details.

Last Rev Date:

2

5

/0

6

/1

9

Page

5

of

1

4

Fitting instructions# 378

93

37

Copyright © 2019 by ARB Corporation Limited. All rights reserved, this document must not be reproduced without the express authority of ARB Corporation Ltd

FITTING PROCEDURE

1. Lay the bar face down on a soft surface so as

not to damage the paint / powder coat.

2. If fitted, carefully remove the winch cover

plate and discard. Keep fasteners for re-use.

Warn Zeon / Platinum winches:

3. Mount the Control Box to the winch cradle

using 4x M6x25 hex head bolts, washers and

spacers provided with this kit.

4. Adjust the control box until it is approximately

5mm clear of front of control box recess and

tighten all fasteners.

M6 - 9 Nm.

5. Route and cable tie the Control Box Cables

clear of the winch spool area.

Control Box Assembled; Rear view shown

HINT:

Apply some split cable protection

conduit to the winch cables where they

pass through the Bull Bar.

Last Rev Date:

2

5

/0

6

/1

9

Page

6

of

1

4

Fitting instructions# 378

93

37

Copyright © 2019 by ARB Corporation Limited. All rights reserved, this document must not be reproduced without the express authority of ARB Corporation Ltd

FITTING PROCEDURE

Warn Magnum winches (“GEN 1”):

6. Remove top cover from winch by removing 3x

M4 bolts from side of plastic cover.

7. Undo 2x supplied M6 nuts from underside of

control box. To do so, top of M6 bolts located

on the inner side of the box will need to be

held in place.

8. Attach control box to control box bracket

using fasteners removed from control box in

earlier step, so that the top face of the bracket

is flush with the bottom surface of the control

box.

Do not fully tighten.

Last Rev Date:

2

5

/0

6

/1

9

Page

7

of

1

4

Fitting instructions# 378

93

37

Copyright © 2019 by ARB Corporation Limited. All rights reserved, this document must not be reproduced without the express authority of ARB Corporation Ltd

FITTING PROCEDURE

9. Secure plastic back onto control box, taking

care to leave the two supplied bolts in

position.

NOTE: ENSURE THE CUT-OUT EDGES OF THE

BRACKET FACE THE FRONT OF THE BAR AS

SHOWN

10. Mount the control box sub-assembly and

cable guard plate to the bar using the 4x

M6x25 bolts, flange nuts and washers

included in this kit. Rear view shown.

11. Adjust the control box until it is approximately

5mm clear of front of control box recess and

tighten all fasteners.

M6 - 9 Nm.

Control Box Assembled; Rear view shown

HINT:

Apply some split cable protection

conduit to the winch cables where they

pass through the Bull Bar then route and

cable tie them clear of the winch spool.

Last Rev Date:

2

5

/0

6

/1

9

Page

8

of

1

4

Fitting instructions# 378

93

37

Copyright © 2019 by ARB Corporation Limited. All rights reserved, this document must not be reproduced without the express authority of ARB Corporation Ltd

FITTING PROCEDURE

Warn Magnum winches (“GEN 2”):

12. Mount the Control Box to the Warn Mount

Plate using the fasteners supplied with the

winch kit, ensuring that the 2x centrally

located M6 hex head bolts pass through the

plates as shown.

13. Adjust the control box until it is approximately

5mm clear of front of control box recess and

tighten all fasteners.

M6 - 9 Nm.

14. Route and cable tie the Control Box Cables

clear of the winch spool area.

Control Box Assembled; Rear view shown

Warn M8000, XD9 & 9.5XP “Contactor” control

box winches.

15. Mount the control box to the 3759658 bracket

in this kit using 2x M6 flange nuts provided,

passing the control box cables past the cut-

out at the rear of the bracket. Rear view

shown.

NOTE: ENSURE THE CUT-OUT EDGES OF THE

BRACKET FACE THE REAR OF THE BAR AS

SHOWN

16. Mount the control box sub-assembly and

cable guard plate to the bar using the 4x

M6x25 bolts, flange nuts and washers

included in this kit.

HINT:

Apply some split cable protection

conduit to the winch cables where they

pass through the Bull Bar then route and

cable tie them clear of the winch spool.

Last Rev Date:

2

5

/0

6

/1

9

Page

9

of

1

4

Fitting instructions# 378

93

37

Copyright © 2019 by ARB Corporation Limited. All rights reserved, this document must not be reproduced without the express authority of ARB Corporation Ltd

17. Adjust the control box until it is approximately

5mm clear of front of control box recess and

tighten all fasteners.

M6 - 9 Nm.

Control Box Assembled; Rear view shown

Smittybilt “GEN 2” winches. Requires Smittybilt

adapter kit 3500770

18. Mount the Control Box to the adapter bracket

included in the 3500770 kit using the M5

hardware provided in the kit.

19. Mount the control box to the 3759658 bracket

in this kit using 2x M6x25 bolts, flange nuts

and washers removed in Step 2, passing the

control box cables past the cut-out at the rear

of the bracket. Rear view shown.

NOTE: ENSURE THE CUT-OUT EDGES OF THE

BRACKET FACE THE REAR OF THE BAR AS

SHOWN

20. Mount the control box sub-assembly and

cable guard plate to the bar using the 4x

M6x25 bolts, flange nuts and washers

included in this kit. Rear view shown.

HINT:

Apply some split cable protection

conduit to the winch cables where they

pass through the Bull Bar then route and

cable tie them clear of the winch spool.

Last Rev Date:

2

5

/0

6

/1

9

Page

10

of

1

4

Fitting instructions# 378

93

37

Copyright © 2019 by ARB Corporation Limited. All rights reserved, this document must not be reproduced without the express authority of ARB Corporation Ltd

21. Adjust the control box until it is approximately

5mm clear of front of control box recess and

tighten all fasteners.

M6 - 9 Nm.

Control Box Assembled; Rear view shown

Bushranger winches “GEN 1”.

22. First remove one plastic end from the control

box. Slide in two Hex head M8x20 bolts. (not

provided).

23. Replace plastic end of the control box and

fasten to bullbar using 2x M8 nut and washer

sets (not provided)

24. If desired optional cover kit 3500780 can be

fitted to back of bushranger control box.

M8 - 22 Nm.

25. Mount the cable guard plate to the bar using

2x M6x25 bolts, flange nuts and washers

included in this kit. Rear view shown.

26. Adjust the control box until it is approximately

5mm clear of front of control box recess and

tighten all fasteners.

M6 - 9 Nm.

Control Box Assembled; Rear view shown

HINT:

Apply some split cable protection

conduit to the winch cables where they

pass through the Bull Bar then route and

cable tie them clear of the winch spool.

HINT:

Apply some split cable protection

conduit to the winch cables where they

pass through the Bull Bar then route and

cable tie them clear of the winch spool.

Last Rev Date:

2

5

/0

6

/1

9

Page

11

of

1

4

Fitting instructions# 378

93

37

Copyright © 2019 by ARB Corporation Limited. All rights reserved, this document must not be reproduced without the express authority of ARB Corporation Ltd

Bushranger REVO winches “GEN 2”.

27. First remove the plastic control box cover

then align the two slots in the base with the

slots in the bar mount. Use at least 2x hex

head M8x20 bolts, washers and nuts to

secure the control box (not provided).

28. Carefully replace the plastic control box cover

and adjust the control box until it is

approximately 5mm clear of front of control

box recess and tighten the M8 fasteners.

M8 - 22 Nm.

29. Mount the cable guard plate to the bar using

2x M6x25 bolts, flange nuts and washers

included in this kit. Rear view shown.

M6 - 9 Nm.

Control Box Assembled; Rear view shown

HINT:

Apply some split cable protection

conduit to the winch cables where they

pass through the Bull Bar then route and

cable tie them clear of the winch spool.

Last Rev Date:

2

5

/0

6

/1

9

Page

12

of

1

4

Fitting instructions# 378

93

37

Copyright © 2019 by ARB Corporation Limited. All rights reserved, this document must not be reproduced without the express authority of ARB Corporation Ltd

Warn XDC control box winches: Requires XDC

adapter kit 3500410.

30. Mount the XDC Control Box to the adapter

bracket included in the 3500410 kit using the

M8 hardware provided in the kit. Note: the

control box cover will need to be removed

and rotated 180 degrees and re-assembled to

the bracket. Rear view shown.

M8 - 22 Nm.

31. Mount the control box to the 3750486 bracket

using the M6 fasteners supplied with the

3500410 kit, passing the control box cables

past the cut-out at the rear of the bracket.

32. Mount the control box sub-assembly and

cable guard plate to the bar using the 4x

M6x25 bolts, flange nuts and washers

included in this kit.

33. Adjust the control box until it is approximately

5mm clear of front of control box recess and

tighten all fasteners.

M6 - 9 Nm.

Control Box Assembled; Rear view shown

HINT:

Apply some split cable protection

conduit to the winch cables where they

pass through the Bull Bar then route and

cable tie them clear of the winch spool.

Last Rev Date:

2

5

/0

6

/1

9

Page

13

of

1

4

Fitting instructions# 378

93

37

Copyright © 2019 by ARB Corporation Limited. All rights reserved, this document must not be reproduced without the express authority of ARB Corporation Ltd

FITTING PROCEDURE

34. Sit the winch in position on the bar’s winch

cradle.

35. Attach the winch to the bar through the top 2

holes using 2 of the bolts (and any washers)

that are supplied with the winch.

36. Level the winch and tighten the bolts.

37. If not already done, mark 2 hole positions

25mm below the centre holes as shown in the

diagram.

38. Drill 2, Ø13mm holes. De-burr the holes and

protect with a zinc rich primer to prevent rust.

Note: Hawse fairleads require kit 3500600

Refer to Hawse fitting kit instructions.

39. Turn the bar over onto the back face.

40. Attach the roller fair lead (RFL) to the bar and

winch using the longer hex bolts supplied in

this kit and any washers supplied with the

winch.

Note 1: To make it easier to get to the bolt

holes in the RFL, remove the vertical roller pins

and rollers.

Note 2: Some winches will require 3/8” UNC

bolts where others will require M10. Both have

been supplied in this kit. Please check the

threads before proceeding. This can be done

by comparing the bolts from this kit with the

ones supplied with the winch.

M10- 44 Nm. 3/8th - 44 Nm.

Warning: Drill

ing operations

can result in flying metal

debris, safety glasses should

be worn.

Last Rev Date:

2

5

/0

6

/1

9

Page

14

of

1

4

Fitting instructions# 378

93

37

Copyright © 2019 by ARB Corporation Limited. All rights reserved, this document must not be reproduced without the express authority of ARB Corporation Ltd

FITTING PROCEDURE

41. Assemble the 2 folding number plate mount brackets together using the M8 hex bolts, Washers,

Packers and Nyloc Nuts as shown in the diagram below.

42. Assemble the bracket assembly to the bar using the fasteners supplied with the bar fitting kit.

Follow the step in the bars fitting instructions showing the fixed license plate bracket being mounted

substituting the folding assembly for the fixed.

M6 – 9 Nm

43. Ensure all cables are attached as per the winch manufacturer’s instructions. Ensure cables are

securely attached and cannot rub on any sharp edges.

44. Tidy the cables and secure using cable ties leaving the 2 long power cables free to be connected to

the vehicles battery later.F

Return to the bar fitment instructions.

NOTE: TRIM HERE, BOTH

SIDES; IF FITTING A

SLIMLINE NUMBER PLATE

Warning: Drill

ing operations

can result in flying metal

debris, safety glasses should

be worn.

This manual suits for next models

1

Table of contents

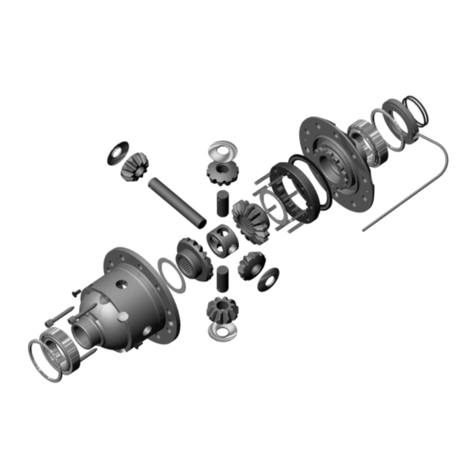

Other ARB Automobile Accessories manuals

ARB

ARB AIR LOCKER RD135 User manual

ARB

ARB RD177 User manual

ARB

ARB AIRLOCKER RD188 User manual

ARB

ARB ESPERANCE 802200 User manual

ARB

ARB INTENSITY SOLIS User manual

ARB

ARB RD246 Product information sheet

ARB

ARB AIRLOCKER RD142 User manual

ARB

ARB 1780500 User manual

ARB

ARB LINX LX100 User manual

ARB

ARB 3432300 User manual

Popular Automobile Accessories manuals by other brands

ULTIMATE SPEED

ULTIMATE SPEED 279746 Assembly and Safety Advice

SSV Works

SSV Works DF-F65 manual

ULTIMATE SPEED

ULTIMATE SPEED CARBON Assembly and Safety Advice

Witter

Witter F174 Fitting instructions

WeatherTech

WeatherTech No-Drill installation instructions

TAUBENREUTHER

TAUBENREUTHER 1-336050 Installation instruction