3

BO-209 MON SUN -Item code: BH122 INSTRUCTION MANUAL.

Caution: this model is not a toy!

If you are a beginner to this type of powered

model,please askan experiencedmodelflyer

forhelp andsupport.Ifyouattempttooperate

themodel withoutknowingwhat youaredoing

you could easily injure yourself or somebody

else. Please keep your safety and well-being

in mind at all times.

Important: before you start construction

Evenifyou havealready built alarge number

ofRC modelspleaseread rightthrough these

instructions and check all the kit components

against the parts list. We have taken great

trouble to keep construction as simple as

possible, without making any compromises

in the area of safety.

Note regarding the film covering

Minor creases or bubbles may develop in the

film covering due to major fluctuations in

weather conditions (temperature, humidity

etc.); in rare cases you may even find a slight

warp in a component. These minor faults are

in the nature of film-covered built-up wooden

structures, and can easily be corrected using

a heat gun, as commonly used for modelling.

Creases: Blowwarm airoverthearea

and rub down with a soft

cloth.

Caution! do not heat the film more than is

absolutely necessary. If the air or the iron is

too hot, the film may melt and holes may be

formed.

This model is highly pre-fabricated and can

bebuilt inaveryshorttime. However,the work

which you have to carry out is important and

must be done carefully. The model will only

be strong and fly well if you complete your

taskscompetently -so pleaseworkslowlyand

accurately.

When self-tapping screws have to be

screwed into wood, apply a little white glue

to prevent them shaking loose: just squirt

white glue into the hole and fit the screw.

+ This is not a toy

+ Be sure that no other flyers are using your

radio frequency.

+Theglowplug clipmustbesecurely attached

to the glow plug.

SAFETY PRECAUTION.

+ Do not flip the propeller with your fingers.

+ Keep loose clothing and wires away from

thepropeller.

+Donot startthe motorif peopleare near. Do

not stand in line with the side of the propeller.

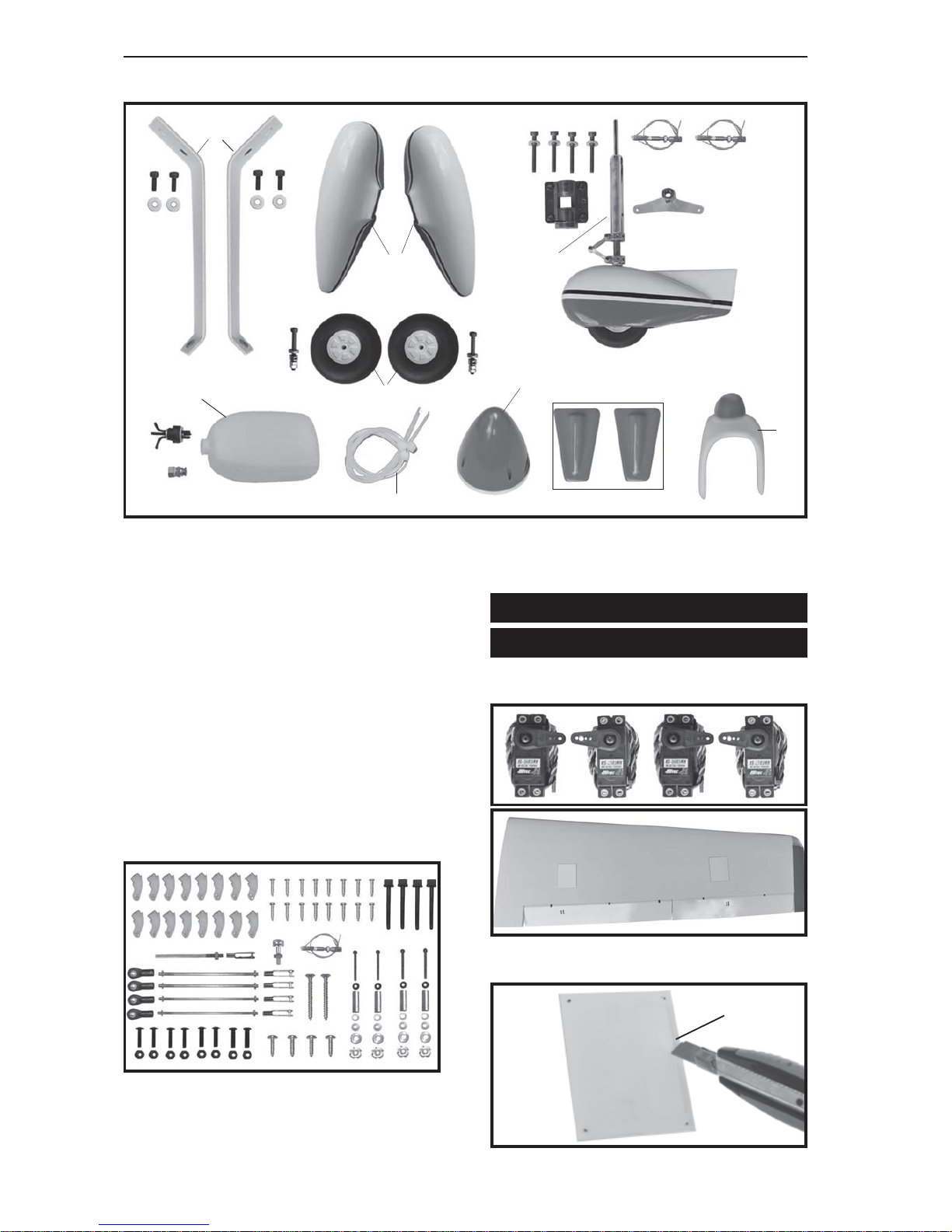

REPLACEMENT LARGE PARTS

Wing warp: Holdthepanel twistedgently

in the opposite direction to

the warp, and apply warm

air to remove the creases

from the covering.

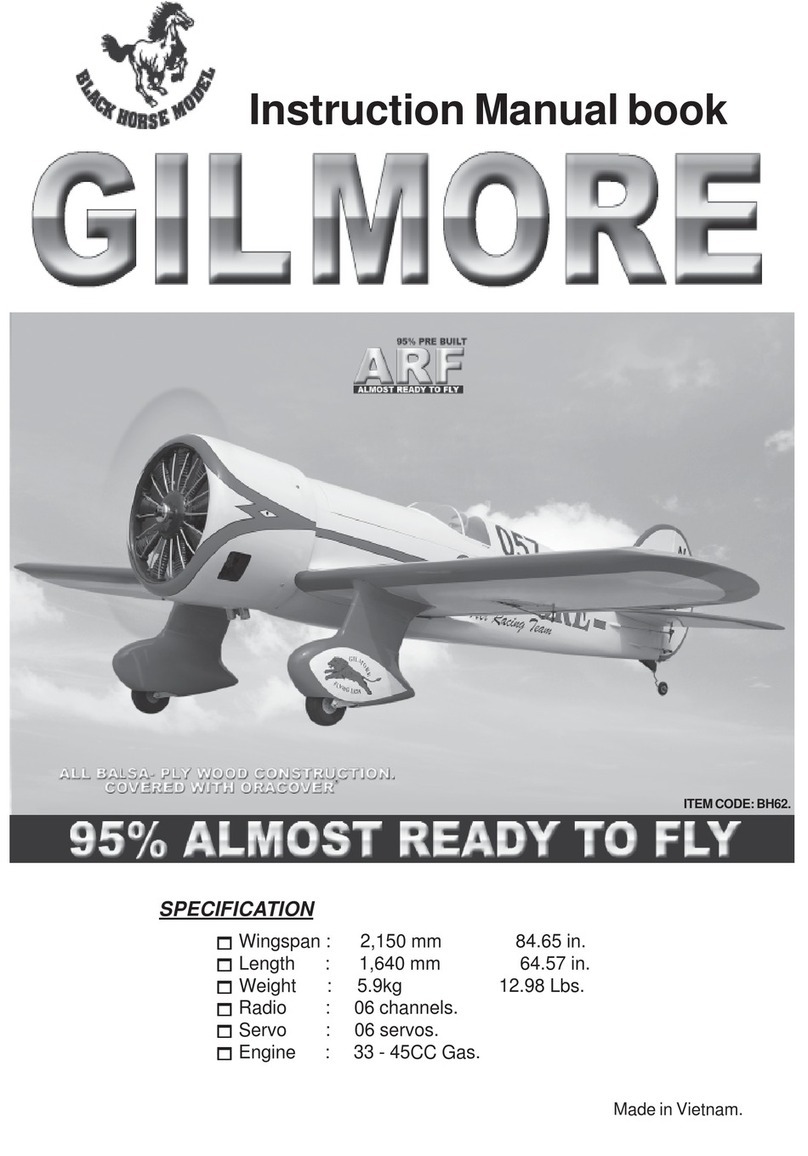

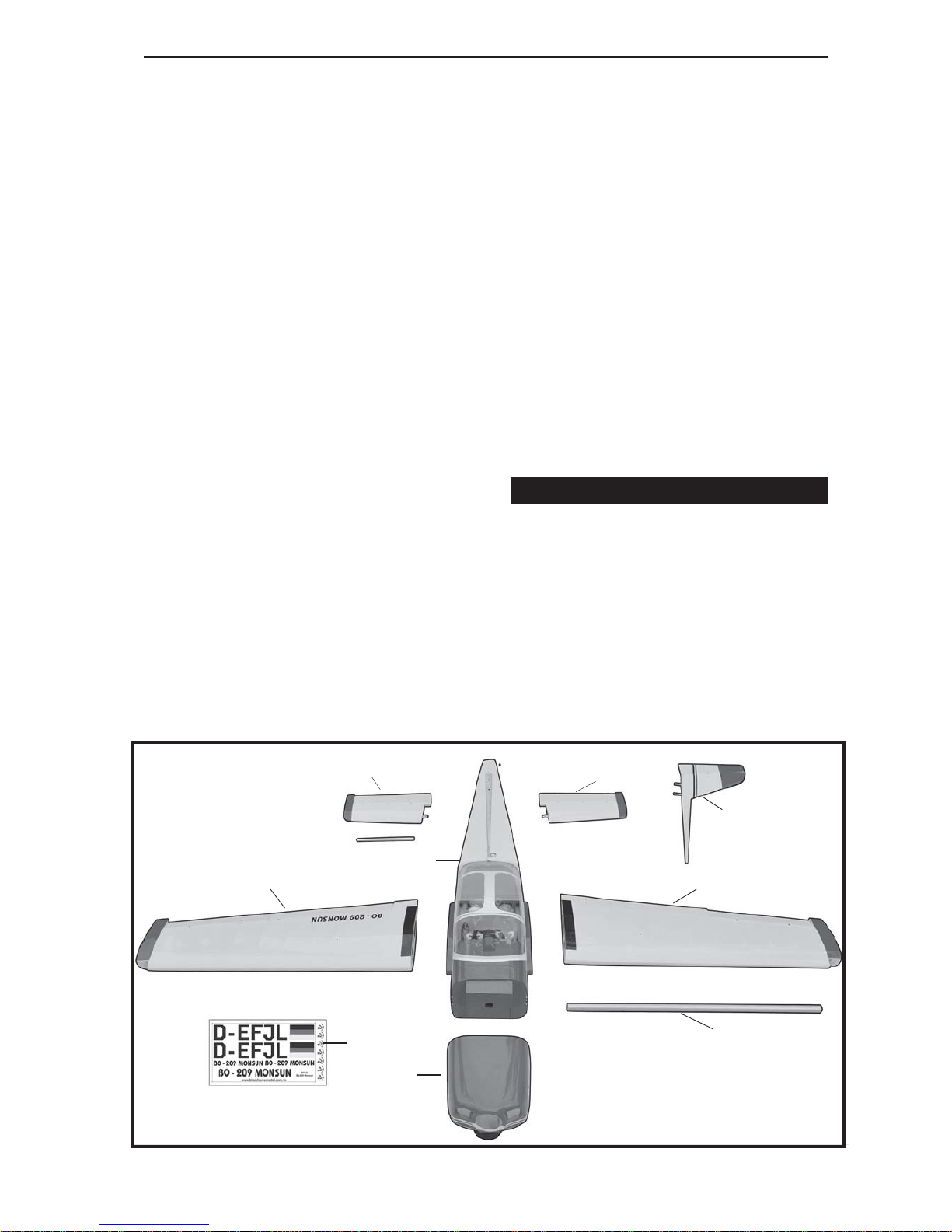

B. Wing panel. D. Horizontal stabilizer.

E. Rudder. F. Aluminium wing dihedral brace.

A.Cowling. G. Decal sheet.

C. Fuselage.

B

A

B.

F.

C.

D. D.

E

G