Parts List

P. 2

TOUGHLON STL 550 PEARL BLUE

TOUGHLON STL 330 CADMIUM YELLOW

TOUGHLON STL 511 PEARL FERRARI RED

COVERING:

1. MAIN WING -- 1 pair

METAL HINGES -- 18 pcs

2. HEAVY DUTY SERVO HORN PL4120300 -- 4 sets

SCREW PM4x85mm -- 2 pcs

SCREW PM4x75mm -- 2 pcs

M4 NYLON INSERT LOCK NUT -- 4 pcs

HEAVY DUTY HORN BRACKET PL4112400 -- 4 sets

HEAVY DUTY CLEVIS PL4112200 -- 8 sets

SWIVEL CLEVIS HORN FAIRING PL4610010 -- 4 sets

PUSHROD Ø2.5x80mm w/ Threads (For Aileron) -- 4 pcs

3. STABILIZER & ELEVATOR -- 1 set

METAL HINGES -- 12 pcs

PUSHROD M3x35mm w/ Threads (For Elevator) -- 2 pcs

HEAVY DUTY HORN BRACKET PL4112400 -- 2 sets

HEAVY DUTY CLEVIS PL4112200 -- 4 sets

HEAVY DUTY SERVO HORN PL4120300 -- 2 sets

SWIVEL CLEVIS HORN FAIRING PL4610010 -- 2 sets

SCREW PM4x65mm -- 2 pcs

M4 NYLON INSERT LOCK NUT -- 2 pcs

4. STABILIZER TUBE Ø22x615mm -- 1 pc.

SCREW PA3x14mm -- 2 pcs

WASHER d3xD7mm -- 2 pcs

FUSELAGE -- 1 pc.

5. VERTICAL FIN & RUDDER -- 1 set

METAL HINGES -- 5 pcs

6. TAIL GEAR ASSEMBLY 20-28LBS PL3410020 -- 1 set

7. FIRE WALL 12x125x164.2mm (F12) -- 1 pc.

ENGINE BOX SIDE PLATE 6x98x330mm (F10) -- 1 pc.

ENGINE BOX SIDE PLATE 6x98x321.7mm (F11) -- 1 pc.

LOWER PLATE 3x159x165mm (F13) -- 1 pc.

BALSA 10x10x98mm (F23) -- 1 pc.

BALSA 10x10x98mm (F24) -- 1 pc.

BALSA 10x10x153mm (F25) -- 1 pc.

BALSA 10x10x98mm (F23A) -- 1 pc.

BALSA 10x10x98mm (F24A) -- 1 pc.

BALSA 10x10x153mm (F2A) -- 1 pc.

WOOD 10x10x98mm (F26) -- 6 pcs

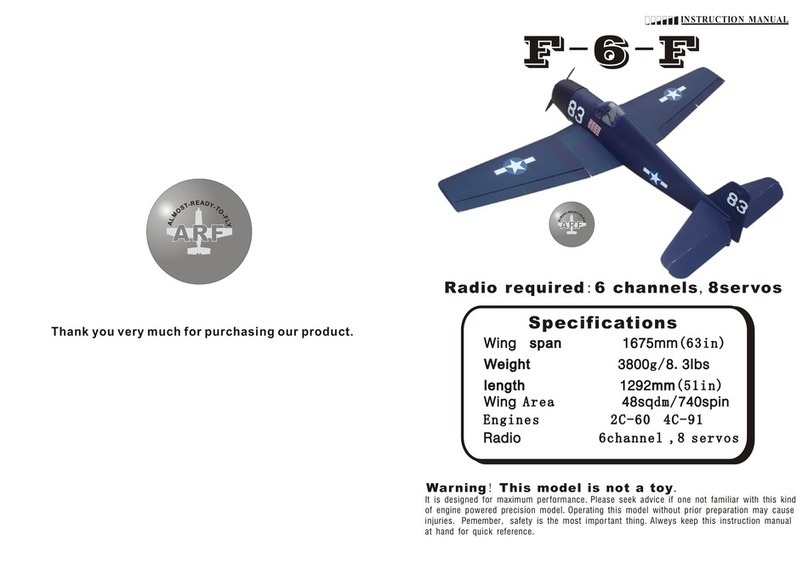

8. MAIN LANDING GEAR -- 1 pc.

MAIN WHEEL Ø102mm -- 2 pcs

AXLE SHAFT Ø5x54mm -- 2 pcs

M8 NYLON INSERT LOCK NUT -- 2 pcs

SCREW PA3x14mm -- 4 pcs

SOCKET HEAD SCREW M6x20mm -- 4 pcs

COLLAR Ø5.2mm w/ set screw -- 4 pcs

WHEEL PANTS -- 1 pair

9. EYE SCREW M2.5x8x25mm w/ Threads (For Rudder) -- 2 pcs

HEAVY DUTY CLEVIS PL4112200 -- 2 sets

HEAVY DUTY HORN BRACKET PL4112400 -- 2 sets

SWIVEL CLEVIS HORN FAIRING PL4610020 -- 1 set

SCREW M4x130mm -- 1 pc.

M4 NYLON INSERT LOCK NUT -- 2 pcs

SWIVEL CLEVIS HORN SUPPORT PL4610120 -- 1 set

SCREW PM2.5x35mm -- 1 pc.

M2.5 NYLON INSERT LOCK NUT -- 1 pc.

WIRE Ø1x1100mm (For Rudder) -- 2 pcs

COPPER TUBE d2.5xD3.2x8mm (For Rudder) -- 2 pcs

10. FUEL TANK 1100cc PL112110G (Gasoline Fuel) -- 1 set

CABLE TIE (Fuel Tank) -- 2 pcs

11. PLYWOOD 3x108x190mm -- 1 pc.

SCREW PWA2.6x12mm -- 4 pcs

M6 BLIND NUT -- 4 pcs

SOCKET HEAD SCREW M6x50mm -- 4 pcs

WASHER d6xD15mm -- 4 pcs

12. EYE SCREW M2.5x8x25mm w/ Threads (For Rudder) -- 2 pcs

PUSHROD M3x35mm w/ Threads (For Rudder) -- 2 pcs

HEAVY DUTY SERVO HORN PL4120600 -- 2 sets

HEAVY DUTY CLEVIS PL4112200 -- 6 sets

COPPER TUBE d2.5xD3.2x8mm (For Rudder) -- 2 pcs

THROTTLE PUSHWIRE Ø1.2x580mm -- 1 pc.

w/ Plastic tube d2xD3x350mm -- 1 pc.

SPONGE -- 2 pcs

LINKAGE CONNECTOR 2.1mm -- 1 set

13. WING TUBE Ø38x1150 -- 1 pc.

SCREW PM3x30mm -- 1 pc.

SCREW PA3x30mm -- 1 pc.

WASHER d3xD7mm -- 2 pcs

WING FAIRING 67x120x330mm -- 1 pair

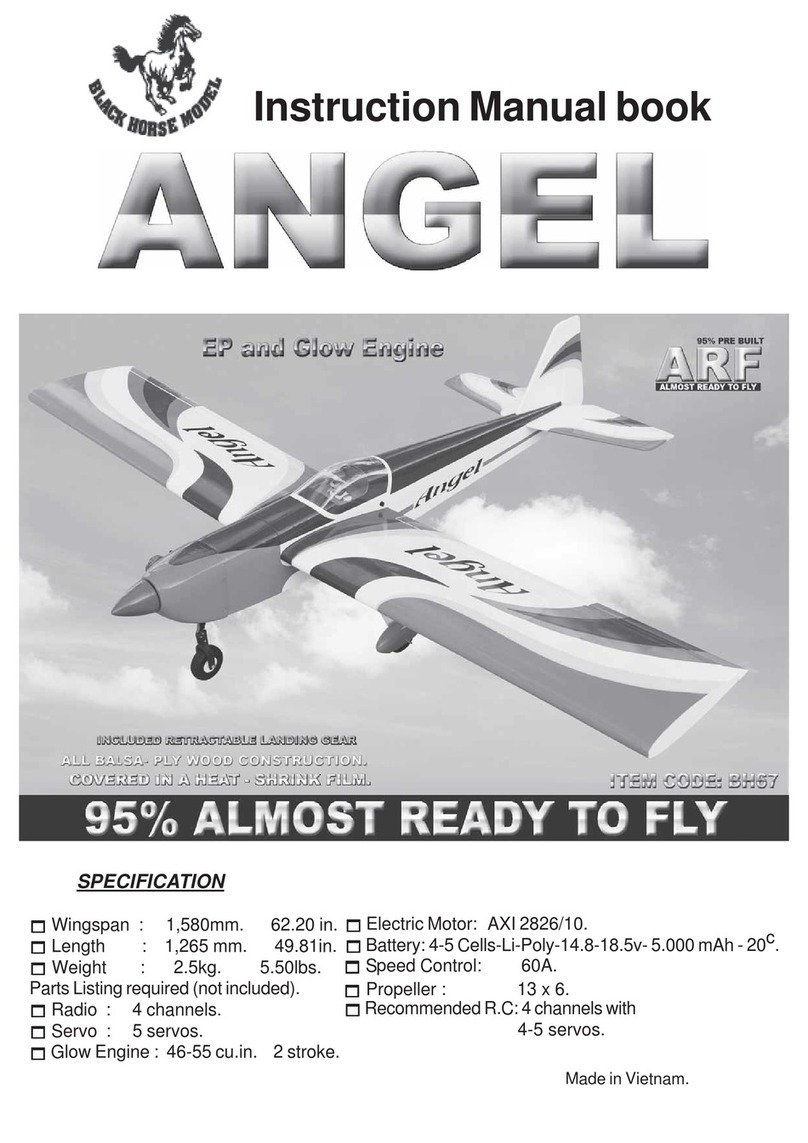

14. COCKPIT -- 1 pc.

CANOPY -- 1 pc.

PILOT (PC101110F) -- 1 pc.

SCREW PWA2.3x12mm -- 6 pcs

SCREW PM3x20mm -- 2 pcs

SILICON GROMMET d1.5xD6.5mm -- 6 pcs

WASHER d3xD7mm -- 2 pcs

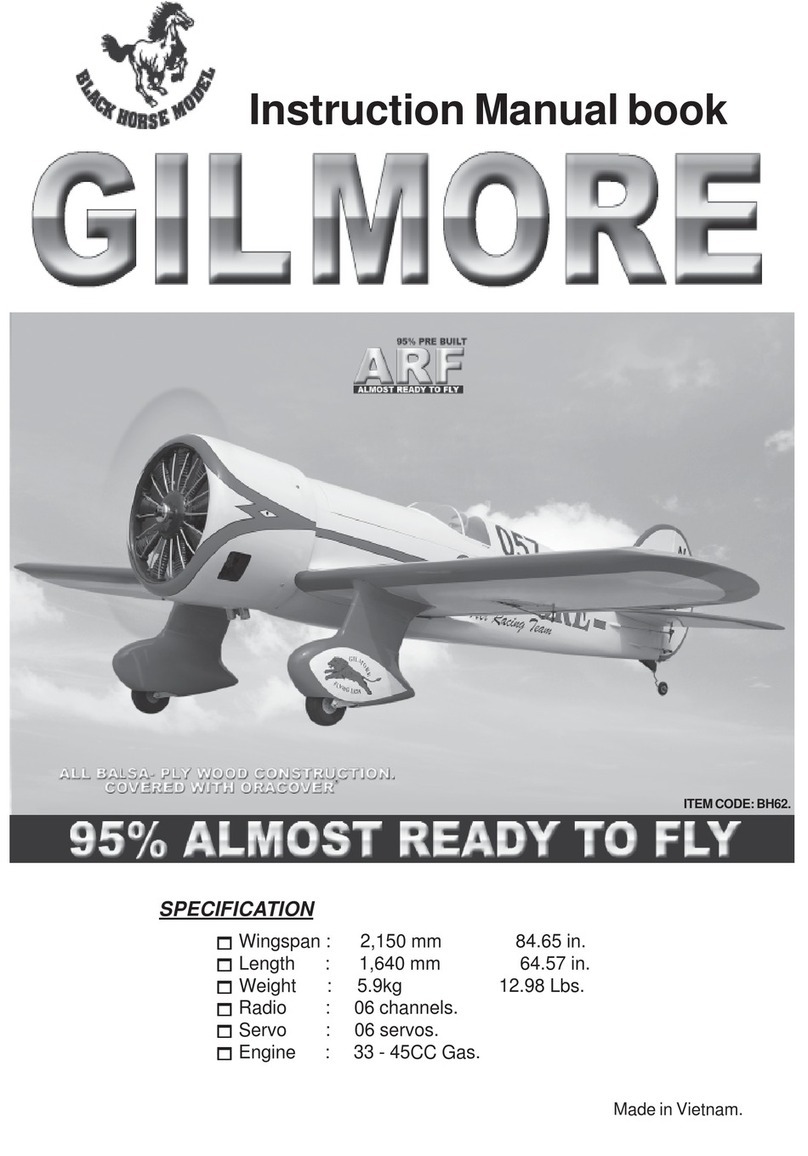

15. COWLING -- 1 pc.

TRANSPARENT 3D TEMPLATE -- 1 pc.

SPINNER Ø102mm (w/ alu. back plate) -- 1 set

SCREW PA3x12mm -- 6 pcs

SILICON GROMMET d2.5xD8.5mm -- 6 pcs

WASHER d3xD7mm -- 6 pcs

16. DECALS -- 1 set