Page 1 of 4

50 Hanover Road, Florham Park, New Jersey 0793 www.ascovalve.com All Rights Reserved.E185 17

GENERAL PURPOSE-WATERTIGHT SOLENOIDS

Installation & Maintenance Instructions SERIES

I&M No. 7501R5

8003P

8007P

8202P

Ċ SERVICE NOTICE Ċ

ASCO solenoid valves with change letter P" in the middle

of the catalog number (ex. 8 10P001) are thermoplastic

encapsulated ASCO RedHat Next Generation Electronic

Solenoids. They are fully encapsulated using Dupontt

Zeniter Liquid Crystal Polymer Resin (LCP). Zeniter LCP

is a thermoplastic polyester resin which exhibits several

advantages over other thermoplastic encapsulants .*

* Chemical resistance of Zeniter LCP is not recommended

for all applications. Zeniter LCP is not suitable for long

term, repeated exposure to high concentrations of caustic

solutions. Consult factory for further information.

Follow these installation and maintenance instructions if

your valve or operator uses this solenoid.

The RedHat Next Generation electronic solenoid has an

integrated management circuit to provide:

SMomentary inrush current for high ratings.

SLow power consumption ( watts holding).

SLow temperature rise.

SVoltage ranging and AC/DC performance.

SBuilt in surge suppression.

See separate instructions for basic valve.

DESCRIPTION

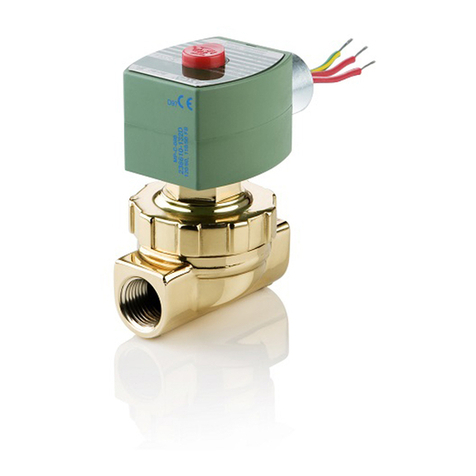

Catalog numbers 8003P and 8007P are plastic

encapsulated pull-type solenoids. The green solenoid

with lead wires and 1/ IĂconduit connection is designed to

meet Enclosure Type 1-General Purpose, Type

-Dripproof, Types 3 and 3S-Raintight, and Types 4 and

4X-Watertight. The gray solenoid valves with catalog

numbers prefixed EE" is designed to meet Enclosure

Types 3 and 3S-Raintight, Types 4 and 4X-Watertight,

Explosionproof Class I, Division Groups A, B, C, & D

and Class II, Division Groups F & G. Operating

Temperature Code T4A (1 0_C).

ASCO Solenoid Valves with P" in the middle of the catalo

number are not suitable for steam service.

See Temperature Limitations section for solenoid

identification and see nameplate for service. When

installed just as a solenoid and not attached to an ASCO

valve, the core has a 0. 50- 8 UNF- B tapped hole, with

0.63 in[16,0 mm] minimum full thread.

Catalog number 8 0 P, is a plastic encapsulated push-type,

reverse-acting solenoid having the same enclosure type as

previously stated for Catalog numbers 8003P and 8007P.

OPERATION

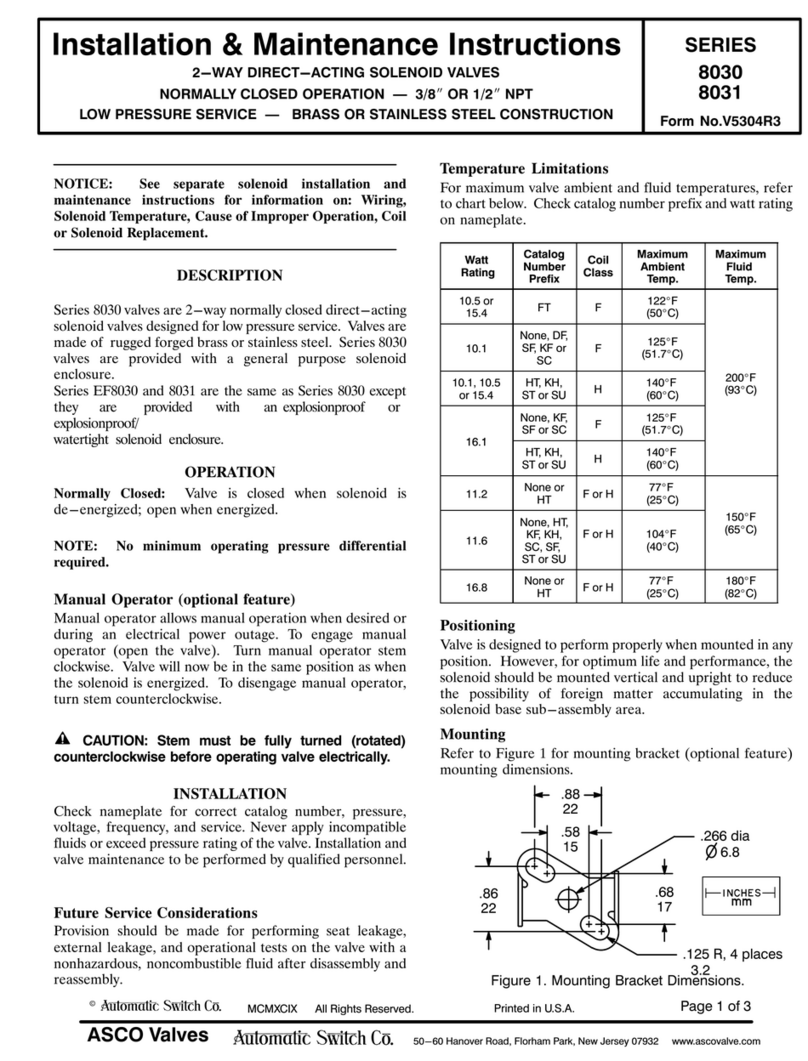

Volta e Ran es: All coils are designed for industrial

operating voltages and can be used on the following voltage

ranges only:

oltage Range Minimum oltage

24-99 /50 or 60Hz/DC (1)

100-240 /50 or 60Hz/DC (1)

(1) =

( ) = Polarity sensitive / Protected: Red wire for Positive (+) and

Black wire for Negative (-). If wired incorrectly, valve will not

operate properly.

Not polarity sensitive

Maximum oltage

:

12-24/DC only (2)

85

20.4

10.4

264

109

26.4

:= As marked on coil

Note: The 100- 40 voltage range is also suitable for battery

charging circuits designed around a 1 5/DC nominal voltage

range. For wider voltage ranges then shown here or for

operating voltage ranges for specific catalog numbers, please

consult your local ASCO sales office.

Series 8003P, 8007P- Solenoid assemblies not supplied as

part of a valve. When the solenoid is energized, the core is

drawn into the solenoid base sub-assembly. IMPORTANT:

When the solenoid is de-ener ized, the initial return force

for the core, whether developed by sprin , pressure, or

wei ht, must exert a minimum force to overcome residual

ma netism created by the solenoid. Minimum return force

is 0.69lbf [3.06 N].

Series 8 0 P - When the solenoid is energized, the disc

holder assembly seats against the orifice. When the solenoid

is de-energized , the disc holder assembly returns.

IMPORTANT: Initial return force for the disc or disc holder

assembly, whether developed by sprin , pressure, or wei ht,

must exert a minimum force to overcome residual

ma netism created by the solenoid. Minimum return force

is 1.30 lbf [5.78 N].

INSTALLATION

Check nameplate for correct catalog number, service, and

wattage. Check side of solenoid for voltage and frequency.

WARNING: Electrical hazard from the

accessibility of live parts. To prevent the possibility

of death,Ăserious injury or property damage, install

the open - frame solenoid in an enclosure.

WARNING: Leakage current from solid state

controls can cause improper operation. Check for

current in the OFF-STATE from the switch with the

solenoid disconnected. Leakage current for solid

state outputs greater then 3 mA must use additional

external loads. Do not use supervisory circuits with

this solenoid.