50-60 Hanover Road, Florham Park, New Jersey 07 32

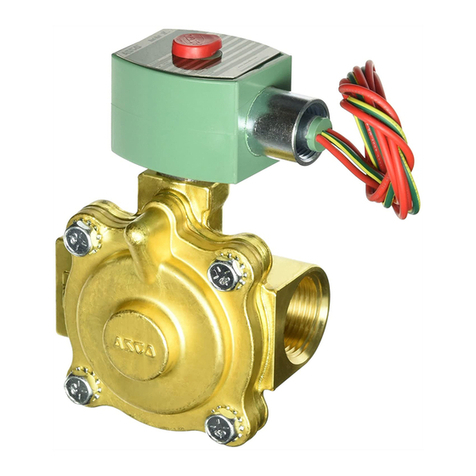

ASCO Valves

Page 2 of 3 Form No. V6 54

CAUTION: To protect the air operated valve, install

a strainer or filter, suitable for the service involved, in

the inlet side as close to the valve as possible. Clean

periodically depending on service conditions. See

ASCO Series 8600, 8601 and 860 for strainers.

MAINTENANCE

WARNING: To prevent the possibility of

personal injury or property damage,

depressurize valve (main and auxiliary

pressure lines), and vent fluid to a safe area

before servicing the valve.

NOTE: It is not necessary to remove the valve from the

pipeline for repairs. However, piping or tubing must be

removed from the auxiliary pressure connection of the air

operator.

Cleaning

All air operated valves should be cleaned periodically. The

time between cleanings will vary depending on the medium

and service conditions. In general, sluggish valve operation,

excessive noise, or leakage will indicate that cleaning is

required. In the extreme case, faulty valve operation will

occur and the valve may fail to open or close. Clean strainer

or filter when cleaning the valve.

Preventive Maintenance

SKeep the medium flowing through the valve as free from

dirt and foreign material as possible.

SWhile in service, the valve should be operated at least

once a month to ensure proper operation.

SDepending on the medium and service conditions,

periodic inspection of internal valve parts for damage or

excessive wear is recommended. Thoroughly clean all

parts. If parts are worn or damaged, install a complete

ASCO Rebuild Kit.

Causes Of Improper Operation

SFailure to Open or Close: Check auxiliary and main line

pressure to valve. Pressure to valve must be within

range specified on nameplate.

SExcessive Leakage: Disassemble valve and clean all

parts. If parts are worn or damaged, install a complete

ASCO Rebuild Kit.

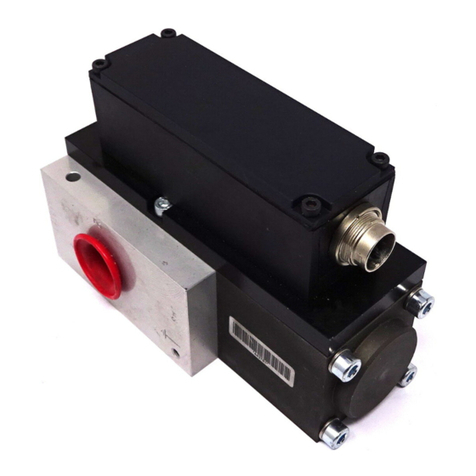

Valve Disassembly

1. Disassemble valve in an orderly fashion using exploded

view for identification and placement of parts.

2. Disconnect tubing or piping from 1 8I NPT auxiliary

pressure connection on air operator assembly.

3. Unscrew operator assembly from main valve body.

Then remove disc holder assembly, disc holder spring

and bonnet gasket.

4. Remove bonnet screws, valve bonnet,

diaphragm spring sub-assembly and body gasket from

valve body.

5. All parts are now accessible for cleaning or

replacement. If parts are worn or damaged, install a

complete ASCO Rebuild Kit.

Valve Reassembly

1. Lubricate body gasket and bonnet gasket with DOW

CORNINGr 200 Fluid lubricant or an equivalent

high-grade silicone fluid.

2. Position body gasket and diaphragm spring

sub-assembly in valve body. Locate bleed hole in

diaphragm spring assembly approximately 45_ from

valve outlet.

Note: Should diaphragm spring sub-assembly become

disassembled, be sure to replace diaphragm spring support

with lip facing upward toward valve bonnet. Then position

the diaphragm spring on the support and assemble the

spring under the cup attached to the diaphragm assembly.

3. When replacing valve bonnet, make certain the

diaphragm spring support is centered on diaphragm

assembly and fits into groove in bonnet. Hand thread

bonnet screws as far as possible into valve body, then

torque screws in a crisscross manner to 95 ± 10 in-lbs

[10, 7 ± 1,1 Nm].

4. Install bonnet gasket, disc holder spring, disc holder

assembly and air operator assembly on valve body.

5. Hand thread air operator assembly onto valve body as

far as possible. Then torque air operator assembly to

175 ± 25 in-lbs [19,8 ± 2,8 Nm].

6. Make up piping or tubing to 1 8I NPT auxiliary

pressure connection on air operator assembly.

WARNING: To prevent the possibility of

personal injury or property damage, check

valve for proper operation before returning to

service. Also perform internal seat and

external leakage tests with a nonhazardous,

noncombustible fluid.

7. Restore main and auxiliary line pressure to valve.

8. After maintenance is completed, operate the valve a

few times to be sure of proper operation.

Torque Chart

Part Name Torque Value

Inch-Pounds

Torque Value

Newton-Meters

Air operator

assembly 175 ± 25 1 ,8 ± 2,8

Bonnet screw 5± 10 10,7 ± 1,1

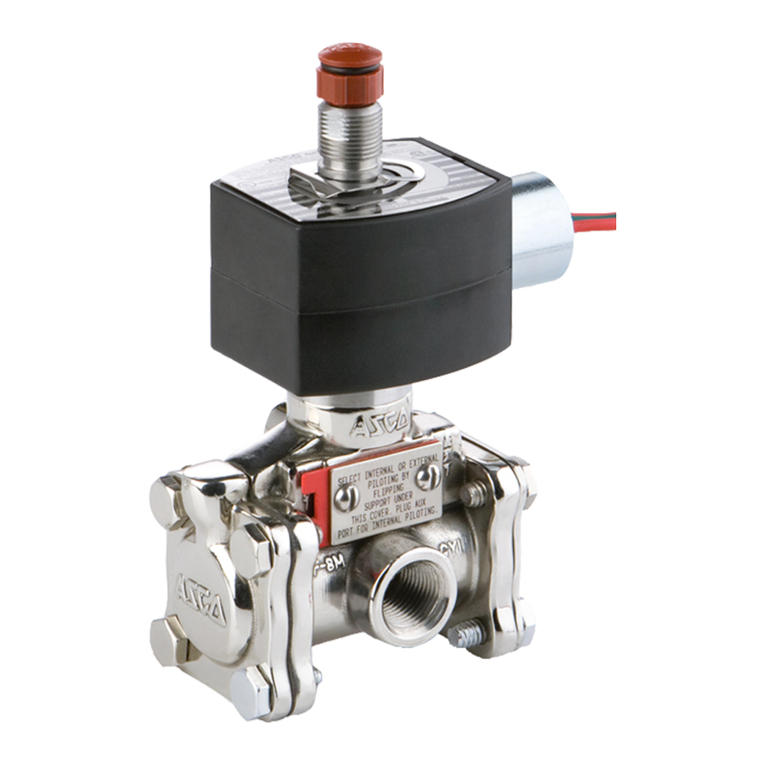

ORDERING INFORMATION

FOR ASCO REBUILD KITS

Parts marked with an asterisk (*) in the exploded views are

supplied in Rebuild Kits. When Ordering Rebuild Kits for

ASCO valves, order the Rebuild Kit number stamped on the

valve nameplate. If the number of the kit is not visible, order

by indicating the number of kits required, and the Catalog

Number and Serial Number of the valve(s) for which they

are intended.