Page 2 of 3

I&M No.V6055R3

EASCO Valve, Inc.R50 Hanover Road, Florham Park, New Jersey 07932 www.ascovalve.com

Wiring

Wiring must comply with local codes and the National

Electrical Code. Housings for all solenoids are provided with

accommodations or connections for 1/2 inch conduit. The

general purpose solenoid enclosure may be rotated to facilitate

wiring by removing the retaining cap or clip.

CAUTION: When metal retaining clip disengages, it will spring

upward. Rotate coil to desired position. Replace retaining clip

before operating.

NOTE: AC and DC solenoids are built differently. To convert

from one to the other, it is necessary to change the complete

solenoid, including the plugnut/core tube sub---assembly and

core assembly.

Solenoid Temperature

Standard catalog valves are supplied with coils designed for

continuous duty service. When the solenoid is energized for a

long period, the solenoid enclosure becomes hot and can be

touched with the hand only for an instant. This is a safe

operating temperature. Any excessive heating will be indicated

by the smoke and odor of a burning coil insulation.

MAINTENANCE

WARNING: To prevent the possibility of death,

personal injury or property damage, turn off

electrical power, depressurize valve, and vent

fluid to a safe area before servicing the valve.

NOTE: It is not necessary to remove the valve from the pipeline for

repairs.

Cleaning

All solenoid valves should be cleaned periodically. The time between

cleanings will vary depending on the medium and service conditions.

In general, if the voltage to the coil is correct, sluggish valve operation,

excessive noise or leakage will indicate that cleaning is required. Inthe

extreme case, faulty valve operation will occur and the valve may fail

to open or close. Clean valve strainer or filter when cleaning the valve.

Preventive Maintenance

SKeep medium flowing through the valve as free from dirt and

foreign material as possible.

SPeriodic exercise of the valve should be considered if ambient

or fluid conditions are such that corrosion, elastomer

degradation, fluid contamination build up, or other

conditions that could impede solenoid valve shifting are

possible. The actual frequency of exercise necessary will

depend on specific operating conditions. A successful

operating history is the best indication of a proper interval

between exercise cycles.

SDepending on the medium and service conditions, periodic

inspection of internal valve parts for damage or excessive wear

is recommended. Thoroughly clean all parts. If parts are worn

or damaged, install a complete rebuild kit.

Causes Of Improper Operation

SFaulty Control Circuit: Check the electrical system by

energizing the solenoid. A metallic click signifies that the

solenoid is operating. Absence of the click indicates the loss of

power supply. Check for loose or blown fuses, open---circuited

or grounded solenoid, broken lead wires or splice connections.

SBurned---Out Solenoid: Check for open---circuited solenoid.

Replace if necessary. Check supply voltage; it must be the same

as specified on nameplate/retainer and marked on the solenoid.

SLow Voltage: Check voltage across the solenoid leads. Voltage

must be at least 85% of rated voltage.

SIncorrect Pressure: Check valve pressure. Pressure to valve must

be within range specified on nameplate.

SExcessive Leakage: Disassemble valve and clean all parts. If parts

are worn or damaged, install a complete ASCO Rebuild Kit.

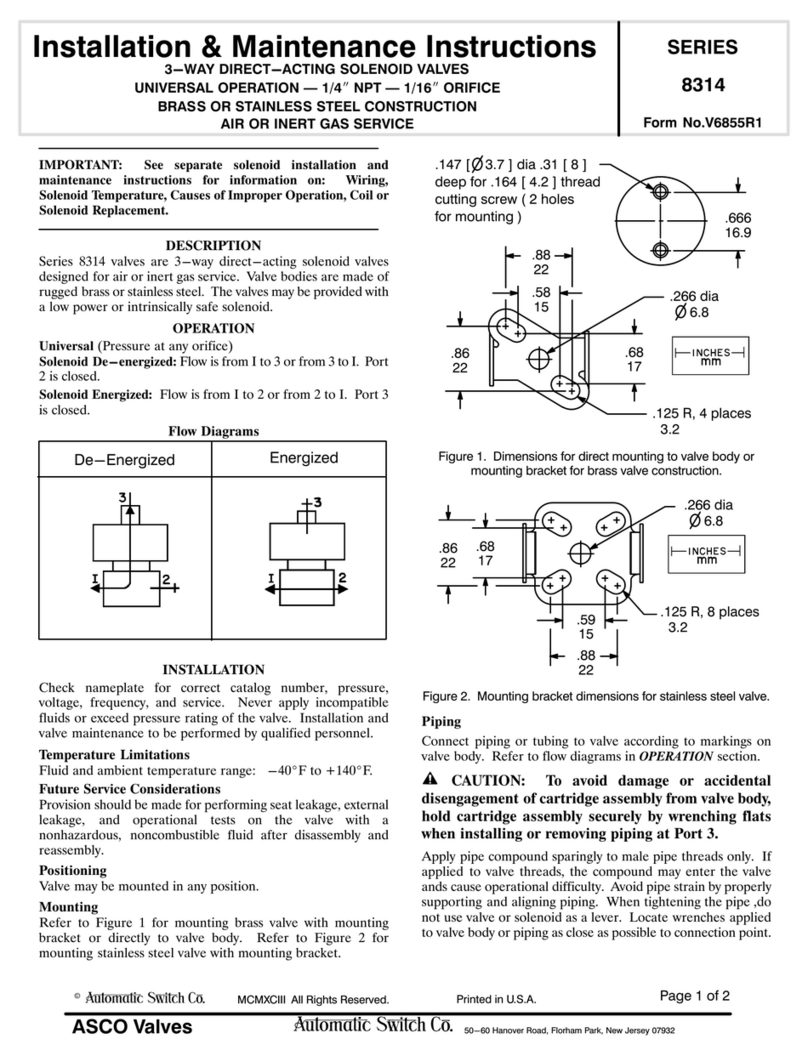

Coil Replacement (Refer to Figure 1)

Turn off electrical power supply and disconnect coil lead wires then

proceed in the following manner:

1. Remove retaining cap or clip, nameplate and cover.

CAUTION: When the metal retaining clip disengages, it will

spring upward.

2. Slip the yokes containing the coil, sleeves and insulating

washers off the plugnut/core tube sub---assembly. Insulating

washers (2) are omitted when a molded coil is used.

3. Slip coil, sleeves and insulating washers from the yoke.

4. Reassemble in reverse order of disassembly paying careful

attention to the exploded view provided for identification

and placement of parts.

CAUTION: The solenoid must be fully reassembled as the

housing and internal parts are part of and complete the

magnetic circuit. Place an insulating washer at each end of

the coil, if required.

Valve Disassembly

Depressurize valve and turn off electrical power supply. Proceed

in the following manner:

1. Remove retaining cap or clip and slip the entire solenoid

enclosureofftheplugnut/coretubesub---assembly.

CAUTION: When metal retaining clip disengages, it will spring

upward.

NOTE: For valves with an Explosionproof/Watertight

Solenoid enclosure, the solenoid may be removed as a

complete unit by unscrewing the solenoid base sub---assembly.

2. Unscrew the valve bonnet with a special wrench adapter

provided in the Spare Parts Kit (special wrench adapter

Order No. 158---477---1).

3. Remove plugnut/core tube sub---assembly with valve bonnet

and bonnet gasket attached.

4. Remove core spring, core assembly and body gasket.

5. Unscrew end cap or manual operator assembly and remove

disc spring, disc, disc holder and body gasket.

6. All parts are now accessible for cleaning or replacement.

Replace worn or damaged parts with a complete Spare Parts

Kit for best results.

Valve Reassembly

1. Reassemble in reverse order of diassembly using exploded

views for identification and placement of parts.

2. Lubricate all gaskets with DOW CORNINGr111

Compound lubricant or an equivalent high---grade silicone

grease.

3. Replace disc holder, disc, disc spring, body gasket and end

cap.

IMPORTANT: Some valves have a disc with a conical point on

one side. Be sure that the conical point on the disc faces the

orifice in the valve body. Torque end cap (or manual operator

assembly) to 9010 inch---lbs (10,21 , 1 N --- m ) .

4. Replace body gasket and install core spring into the core

assembly. Install wide end of core spring into core assembly

first, closed end protrudes from top of core assembly.