50-60 anover Road, Florham Park, New Jersey 07932 www.ascovalve.com ASCO Valves

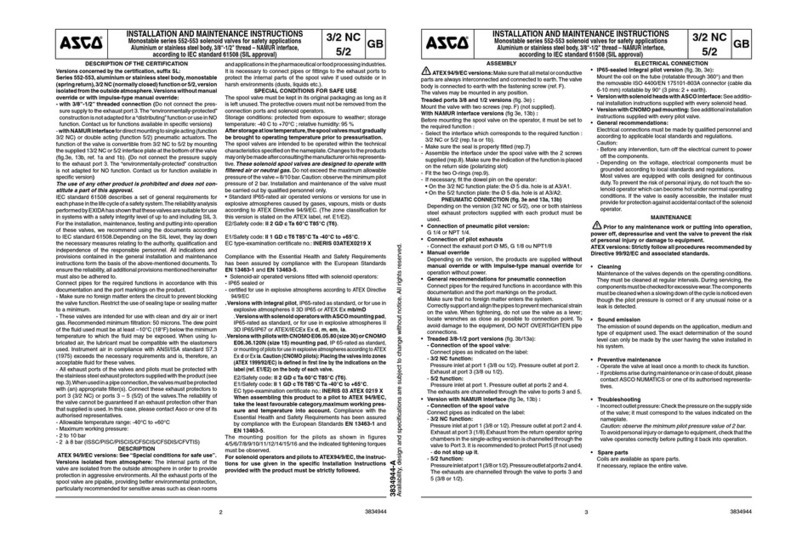

Page 2 of 4 Form No.V5338R3

M INTEN NCE

WARNING: To prevent the possibility death,

serious injury or property damage, turn off

electrical power, depressurize valve, and vent

fluid to a safe area before servicing the valve.

NOTE: Piping must e removed from inlet side of valve

ody.

Cleaning

All solenoid valves should e cleaned periodically.

The time etween cleanings will vary depending on the

medium and service conditions. In general, if the

voltage to the coil is correct, sluggish valve operation,

excessive noise or leakage will indicate that cleaning is

required. In the extreme case, faulty valve operation

will occur and the valve may fail to open or close. Clean

valve strainer or filter when cleaning the valve.

Preventive Maintenance

1. Keep the medium flowing through the valve as free from

dirt and foreign material as possi le.

2. While in service, the valve should e operated at least

once a month to insure proper opening and closing.

3. Depending on the medium and service conditions,

periodic inspection of internal valve parts for damage or

excessive wear is recommended. Thoroughly clean all

parts. If parts are worn or damaged, install a complete

ASCO Re uild Kit.

Causes of Improper Operation

1. Incorrect Pressure: Check valve pressure. Pressure to

valve must e within range specified on nameplate.

2. Excessive Leakage: Disassem le valve and clean all

parts. If parts are worn or damaged, install a complete

ASCO Re uild Kit.

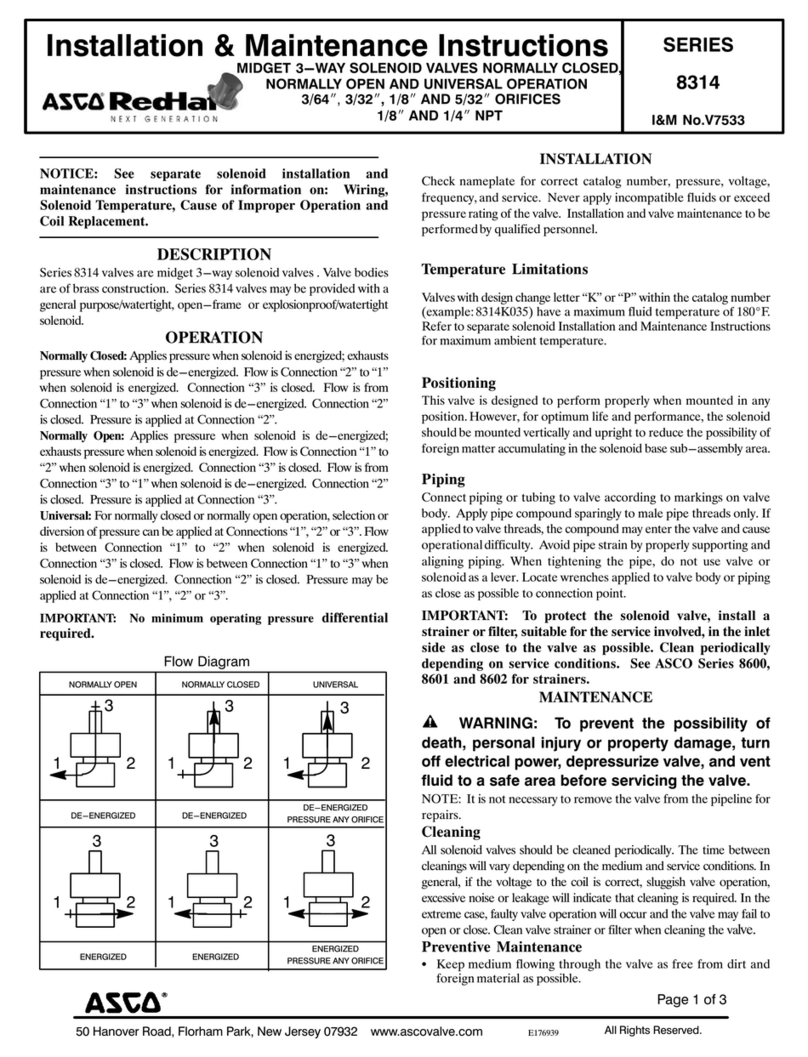

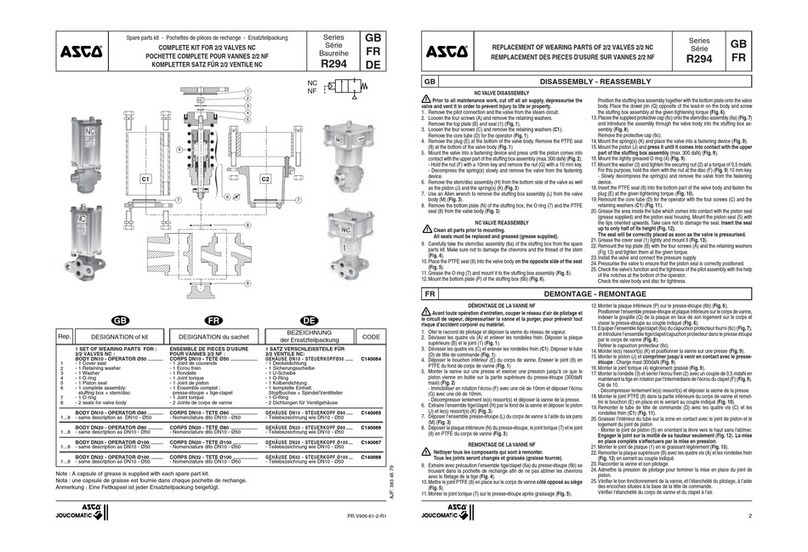

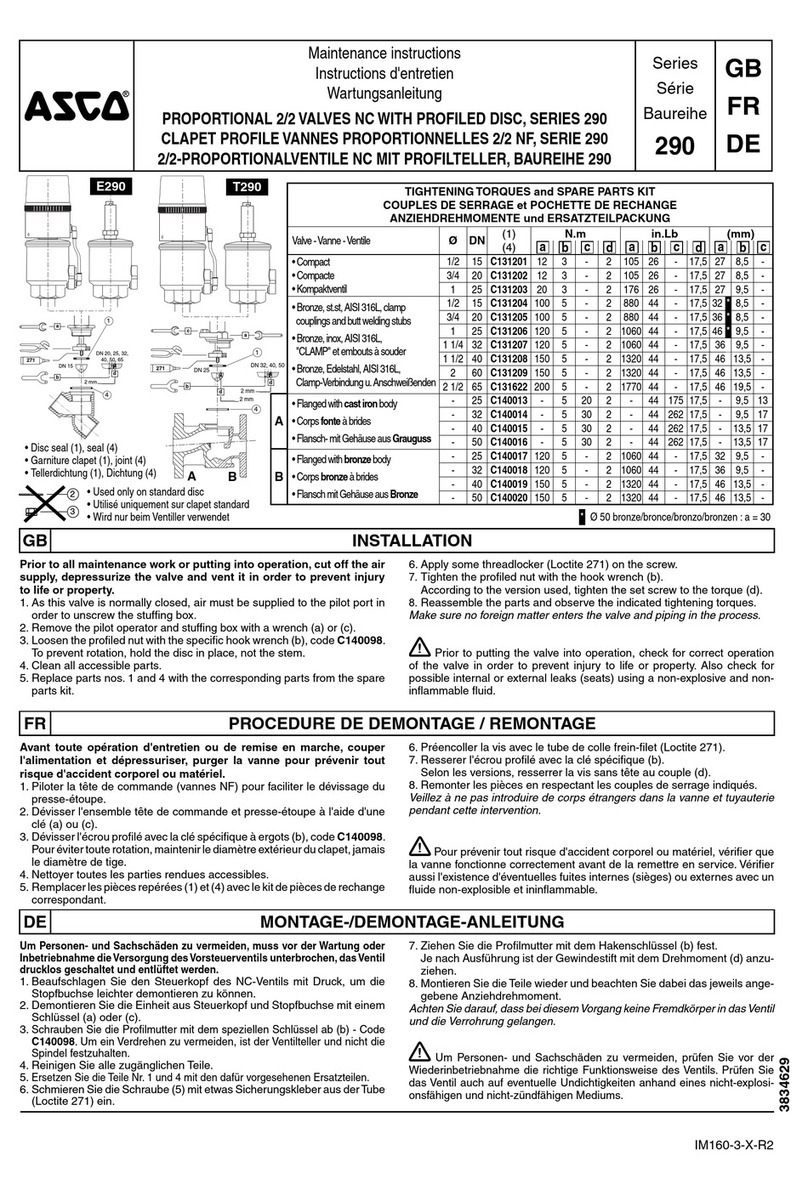

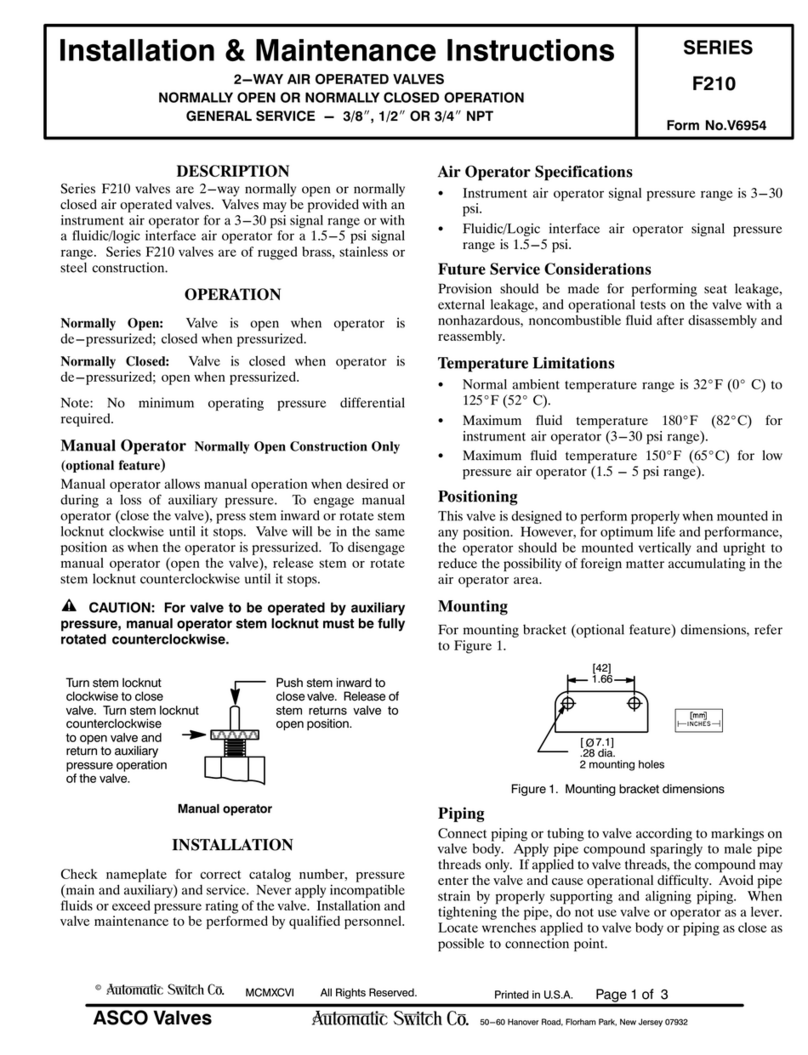

Valve Disassembly (Refer to Figure 1 &2)

1. Disassem le valve in an orderly fashion. Use exploded

views for identification and placement of parts.

2. Remove solenoid, see separate instructions.

3. Unscrew solenoid ase su -assem ly from valve ody.

4. Remove pipe adapter screws and lockwashers (2). Then

remove pipe adapter, adapter gasket, disc spring, and

disc guide from valve ody.

5. Slip core/disc su -assem ly with retainer guide

su -assem ly and core spring from valve ody

6. Remove solenoid ase gasket from valve ody.

7. Remove valve seat with seat gasket from valve ody.

CAUTION: During removal for cleaning, do not

damage seating surface of valve seat (see Figure

1&2).

NOTE: If seat removal is difficult, remove valve ody

from pipe line and dislodge seat through valve outlet. Use

a wooden dowel or similar tool.

8. All parts are now accessi le to clean or replace. If parts

are worn or damaged, install a complete ASCO Re uild

Kit.

Valve Reassembly

1. Lu ricate seat gasket with DOW CORNINGR 111

compound lu ricant or with an equivalent high-grade

silicone grease. Then install seat gasket in groove of valve

seat.

2. Insert valve seat gasket end first into valve ody. Use a

ru er tool to prevent damage to the seating surface of the

valve seat. Apply pressure until valve seat ottoms in valve

ody.

NOTE: When installing a vale seat in a 3/4I NPT valve

(see Figure 2) the elongated hole in the seat must e

aligned horizontal to mate with the hole in the core/disc

su -assem ly.

3. Install core/disc su -assem ly with sharp edge of hole in

core/disc su -assem ly toward valve seat.

4. Install disc guide large diameter end first into valve ody.

Then position disc spring on disc guide.

5. Lu ricate solenoid ase gasket and adapter gasket with

DOW CORNINGR 200 Fluid lu ricant or with an

equivalent high-grade silicone fluid.

6. Position adapter gasket on pipe adapter.

7. Install pipe adapter with gasket on valve ody.

CAUTION: Align pipe adapter evenly with

valve body to avoid damage to adapter gasket

8. Holding the pipe adapter in alignment, replace screws

with lockwashers (lockwashers use on 3/4I NPT valves

only). Torque screws evenly to 95± 10 in-l s

[10,5±1,1Nm].

9. Position solenoid ase gasket in valve ody.

10. Install core spring small end first into the top of the

core/disc su -assem ly. Then install retainer/guide

su -assem ly.

11. For 3/4INPT Valves with a raintight /explosionproof or

raintight/watertight/explosionproof solenoid enclosure,

torque onnet adapter to 175±25 in-l s [ 19,8±2,8 Nm].

12. Install solenoid ase su -assem ly into valve ody.

Torque solenoid ase su -assem ly to 300±30 in-l s

[33,9±3,4 Nm].

13. Replace solenoid (see separate instructions) and make

electrical hookup.

14. Makeup piping to inlet side of valve ody.

WARNING: To prevent the possibility of

death, serious injury or property damage,

check valve for proper operation before

returning to service. Also perform internal

seat and external leakage tests with a

nonhazardous, noncombustible fluid.

15. Restore line pressure and electrical power supply to

valve.

16. After maintenance is completed, operate the valve a few

times to e sure of proper operation. A metallic click"

signifies the solenoid is operating.