Atmos C 451 User manual

ATMOS C 451

Surgical Suction Unit

340.0300.B USA

2013-08 Index: 17

Operating Instructions

English

2

ATMOS

MedizinTechnik GmbH & Co. KG

Ludwig-Kegel-Str. 16

79853 Lenzkirch

Deutschland / Germany

Tel. + 49 (0) 76 53 / 689-0

Fax: + 49 (0) 76 53 / 689-190

+ 49 (0) 76 53 / 689-393 (Service Center)

www.atmosmed.de

5.0 Options .........................................................11-13

5.1 Foot switch..........................................................11

5.2 System trolley .....................................................11

5.2.1 Securing the unit.................................................12

5.2.2 Travelling with the trolley ....................................12

5.3 Tray in foot of system trolley ...............................13

5.4 Potential equalisation..........................................13

5.5 Use of suction unit with disposable systems.......13

5.6 Battery Backup System.......................................13

6.0 Cleaning....................................................... 14-15

6.1 General information on cleaning

and disinfection...................................................14

6.2 Cleaning and sterilizing the unit surface .............15

6.3 Recommended disinfectants for instruments......15

6.4 Recommended disinfections for surfaces...........15

7.0 Maintenance ......................................................15

7.1 Change fuse........................................................16

8.0 Trouble-shooting...............................................16

9.0 Accessories, consumables and

spare parts................................................... 18-18

10.0 Technicalspecications..................................19

11.0 Checking / Reprocessing / Disposal...............20

11.1 Checking ATMOS suction devices......................20

11.2 Reprocessing......................................................20

11.3 Disposal ..............................................................20

12.0 Notes on EMC.............................................. 21-23

General Standard Terms and Conditions

Content

Page

1.0 Introduction..................................................... 3-5

1.1 Notes on operating instructions ............................3

1.2 Intended use .........................................................3

1.3 Function ................................................................3

1.4 Explanation of pictures and symbols ....................4

1.5 Scope of supply ....................................................5

1.6 Transport and storage...........................................5

2.0 For your safety ...................................................6

3.0 Setting up ........................................................ 7-8

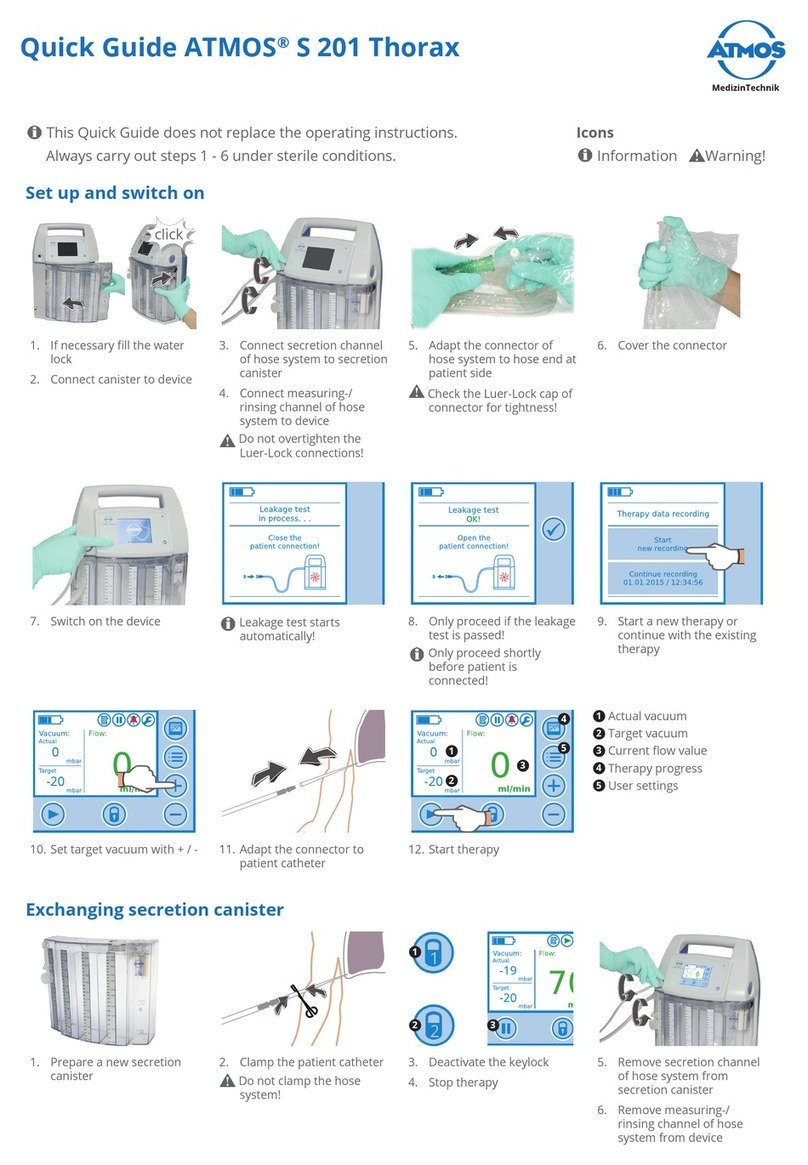

3.1 Operating elements...............................................7

3.2 Connection area in unit base ................................8

4.0 Operating....................................................... 9-10

4.1 On/off switch .........................................................9

4.12 Set vacuum...........................................................9

4.3 Suction................................................................10

3

1.2 Intended use

The Surgical Suction Unit ATMOS C 451 is a compact suction

unit for medical application. It is especially intended for aspira-

tionandcollectionofsecretions,bodyuidsandtissue.

Itsmaineldsofapplicationare:

– in the OPD, in the OR: for sucking off and collecting e.g.

drain pockets, abscesses, body and rinsing solutions

and during lipectomy;

– in endoscopy: e.g. to aspirate secretions or rinsing so-

lutionsaswellasforoperativexation;

– in gynaecology: for suction curettage;

– In ENT applications: to aspirate secretions, rinsing so-

lutions, cerumen or to extract foreign matters;

– in the ward, recovery ward and ICU: : for the spon-ta-

neousaspirationofbodyuidsandforeignmatters,e.g.

from the respiratory tract.

Contraindications for Use:

– Exposed arteries, veins or organs, Untreated

osteomyelitis, Necrotic tissue, Malignancies, and

Fistulas.

– for smoke evacuation in connection with

HF-electrosurgery or laser surgery.

1.3 Function

The ATMOS C 451 is a line-power operated surgical suction

unit, centering around a silent diaphragm-type pump which

generates a vacuum inside a collection jar. Using a vacuum

regulator and the vacuum-gauge, the target vacuum and

thustheair-owratecanbepreciselyadjusted.

A system trolley is available for mobile use.

1.0 Introduction

1.1 Notes on operating instructions

These operating instructions contain important notes on how to operate the ATMOS C 451

safely, correctly and effectively. Reading this booklet helps avoid risks, and also to reduce repair

costs

and down-time. That increases, amongst other things, the reliability and service-life of the device.

These operating instructions serve not only for new operating personnel to be instructed in its use,

but also for use as a reference manual. Any reprint - even in extracts - only after written permission

from ATMOS.

These operating instructions must always be kept available near the device.

Care and safety inspections in conjunction with professional execution provide for operational safety

and readiness for use of your ATMOS C 451 and are therefore a must besides regular cleaning.

Repair work and safety inspections may be carried out only by expert personnel authorised by

ATMOS. By applying only original spare parts you will have the guarantee that operational safety,

readiness for work and the value of your ATMOS C 451 will be preserved.

Warning:

– Do not use in non-medical applications;

– Do not use for emergency medical aid.

– Do not use in the presence of combustible or

explosiveuidsorgases.

– Do not use for drainage in the low vacuum range

(e.g. thorax drainage).

Caution: Federal law restricts this device to sale by or

on the order of a physician.

●The product ATMOS C 451 bears CE marking CE 0124

according to the EC Directive of the

council for medical products 93/42/EEC and meets the

basic requirements of appedix I of this

directive.

●The quality management system applied at ATMOS

hasbeencertiedaccordingtointernational

standards EN ISO 9001 and EN ISO 13485.

●Prior to start-up please peruse chapter 2.0

„For your safety“, in order to be prepared for any

possible dangerous situations.

●The product ATMOS C 451 bears CE marking CE 0124 according to the EC Directive of the

council for medical products 93/42/EEC and meets the basic requirements of appedix I of this

directive.

●ThequalitymanagementsystemappliedatATMOShasbeencertiedaccordingtointernational

standards EN ISO 9001 and EN ISO 13485.

●Prior to start-up please peruse chapter 2.0 „For your safety“, in order to be prepared for any

possible dangerous situations.

4

1.0 Introduction

!

■

●

→

click

click

Important information

Keys on the control panel / symbols at the ATMOS C 451

REF

SN

~

Foot switch

IPX1

Observe operating instructions

1.4 Explanation of pictures and symbols

Short cuts / symbols contained in this manual

Please press where

dot indicates

Subnumeration

Numeration

General information

Follow the arrows

whilst proceeding,

sequence

Replace

Check

Please read,

important information

Move, plug ... in this

direction

Engage, check correct

t

Turn, shift ... in this

direction

Warning, especial diligent

notice

Pictures contained in this manual

Off (feed-in, power

connection)

On (feed-in, power

connection)

Alternating current

Application part type BF

Fuse

Potential equalization

The CE sign shows that this

product meets the appropriate

requirements of the

EC Directives

Serial number

Order number

Creation date

Protection class II

Protection against penetration of

damaging humidity (drop water)

5

1.0 Introduction

Basic device

Operating

instructions

Mains cable Trolley

Optional:

1.5 Scope of supply

●Prior to dispatch, this ATMOS device was subjected to an extensive functional test and has been carefully packed.

Nevertheless, please compare the contents of the shipment on completeness immediately upon receipt (see delivery note).

In addition to the basic device, the scope of delivery comprises the following parts:

1.6 Transport and storage

● Thetransportofthedevicemaybeeffectedonlyinadispatch

cartonupholsteredandofferingsufcientprotection.

● Pleasedocumentandreportdamagesintransitimmediately.

For complaints or return deliveries, please use the enclosed

form QD 434.

●The unit must be allowed to stand for up to six hours at room

temperaturepriortostartingupforthersttimefollowing

transport at temperatures below freezing. The unit may not

be operated if it has not acclimatised as this might damage its

diaphragms.

●Ambient conditions:

Transport/Storage: -22...+122°F;

5...90 % humidity

non-condensing

at air pressure 700...1060 hPa

Operation: +50...+95°F;

20...80 % humidity

non-condensing

at air pressure 700...1060 hPa

System

trolley

6

!

For your safety

The ATMOS C 451 fully complies with the electromagnetic

immunity requirements of standard IEC 60601-1-2 / EN

60601-1-2 "Electromagnetic compatibility - Medical Elec-

trical Equipment".

Warranty period for this unit: 2 years. This period is

unaffected by any repair or maintenance carried out under

the terms of the warranty. Please also pay attention to our

enclosed General Standard Terms and Conditions.

The warranty will be rendered invalid in case of damages

caused due to the utilization of accessories or consumables

which are not approved by ATMOS for use with this unit.

ATMOS is not liable for personal injury and damage to

property if

• nooriginalATMOSpartsarebeingused,

• theadviceforuseintheseoperatinginstructionsisnot

being observed,

• assembly, new settings, alterations, extensions and

repairs have been carried out by personnel not

authorised by ATMOS.

This operation manual corresponds with the construction

of the unit and with the current status of safety-related

standards at the time of printing. Proprietary rights are exi-

sting for all described circuits, processes, names, software

programs and units.

The design of the ATMOS C 451 fulllstherequirements

of IEC 60601-1/EN 60601-1 and of protection class I. The

device must only be connected to a properly installed

socket with non-fused earthed wire.

Before putting the device into operation, visually check

unit, power cable and accessories for signs of damage.

Damaged cables must be replaced immediately. Check

also function of the unit.

The ATMOS C 451 may be used in supervised operation

by qualied personnel only which has been authorised

by ATMOS and which has been trained for operating the

appliance (IEC 60601-1/EN 60601-1).

The ATMOS C 451 may be operated only in rooms used

for medical purposes, but not in areas (zones M and G)

subject to explosion hazards and in oxygen rich envi-

ronments. Explosion harzards may result from the use of

combustible anaesthetic agents, skin cleansing agents or

disinfectants.

The foot switch is suited for operation in above mentioned

areas.

Liquids must not be allowed to enter the device. Should

liquids have penetrated into the device, it must be inspec-

ted (danger of an electric shock) and the pump must be

decontaminated resp. exchanged (infection risk).

After transport at cold temperatures (below the freezing

point), the unit must acclimatize prior to rst use; leave

it unoperated at room temperature for a period of up to 6

hours. If the unit is not acclimatized it must not be operated

as the membranes of the pump might get damaged.

Dispose of the packaging material, observing the appli-

cable waste-control regulations.

Before connecting the device to the power line, check that

the voltage and frequency ratings of the power line are

similar to those indicated on the device.

Never connect the unit to defective power sockets or ex-

tension cables.

Whendisconnectingthedevicefromthepowerline,rst

remove the plug from the wall outlet. Then the power cord

may be disconnected from the device. Never touch the

plug or cord while your hands are wet.

Theambientconditionsspeciedinsection10.0mustbe

strictly observed.

Set up the device so that the operator has a clear, unob-

structed view of and easy access to the front panel. The

device must be placed on a solid, level surface.

This product is not re-sterilisable. Repeated reuse of

components which are marked with a is forbidden.

In case of repeated reuse these components lose their

function and there is a high infection risk.

2.0 For your safety

2

7

Fig. 1.

Fig. 2.

3.0 Setting up

Always set the equipment up on a secure, level surface.

3.1 Operating elements

On/Off switch with pilot lamp

Vacuumgauge

Vacuum controller

8

Fig. 4.

Fig. 5.

Fig. 7.

Fig.6.

3.2 Connection area in unit base

Connect mains cable

Use only mains cables with angled inlet connector for

non-heating appliances!

Check that the voltage and frequency ratings of the power

line are similar to those indicated on the device.

Connect footswitch (optional)

Thread knurled nut onto hose.

Push hose onto connecting nipple.

Tighten knurled nut.

Vacuum connection on base system trolley

Toconnect,presscouplingrmlyintosocketuntillatched

into place (serves for vacuum connection of collection jar

attached to system trolley).

To remove, press the metal interlocking device apart side-

ways and pull the hose out of the socket.

3.0 Setting up

9

Fig. 8.

Fig. 9.

4.1 On/off switch

Press the ”I” symbol to switch the unit on.

Press the ”0” symbol to switch the unit off.

The unit is ready for optional footswitch operation in the

„0“ position (see options).

4.2 Set vacuum

Close the suction hose and set the desired vacuum by

turning the vacuum controller according to the direction of

the arrow.

Do not use force to turn the knob at its limits!

Test the system for leaks if the desired vacuum is not

reached. (Please also see chapter 8.0 Trouble shooting)

4.0 Operation

10

4.3 Suction

Use appropriate suction tubes, catheters, suction tips or

suction instruments, containers and hoses.

Prior to starting suction, containers must be checked for

cracks. Damaged containers may not be used.

Keep an eye on the level of liquid in the collection jar during

suction.

Use only containers with oversuction protection.

4.0 Operation

11

Fig. 10.

Fig 11.

5.0 Options

5.1 Foot switch (REF 340.0060.0)

The foot switch works pneumatically and is therefore sui-

tableforuseinconnection withammableanaesthetics

(class AP).

Connect the foot switch as shown in section 3.2.

Set the unit to ”0” off at the main switch (foot switch

mode).

The unit is switched on by pressing the foot switch and

switched off by pressing it again.

5.2 System trolley

A system trolley, which can be used with a changeover

adapter is available for use in the OT.

Always position the system trolley on a at, sturdy sur-

face.

12

Fig. 12.

Fig. 13.

Fig. 14.

Use the lockable castors if necessary.

5.2.2 Travelling with the trolley

Always push the trolley so that the open fork of the pedestal

faces in the direction of travel.

Push the suction unit using both hands in the handle

area.

Ensure that hoses and cables are secured in place.

Never leave the system trolley on a sloping surface!

5.2.1 Securing the unit

It is only possible to ensure safe operation as a mobile

suction unit by using the special system trolley available

for use with the unit!

The suction unit is placed on the system trolley so that its

feet lock into place in the holes of the unit carrier and it

canbermlyattachedtotheunitcarrierfromunderneath

by means of a knurled screw.

It is imperative that the unit is securely attached to the

system trolley to ensure safe operation and safe travel!

5.0 Options

13

Fig. 15.

Fig. 16.

Fig. 17.

Fig. 18.

5.4 Potential equalisation

(REF 340.0082.0)

A potential equalization connector may be installed on the

system trolley (in the installation groove) as an optional

extra. Installation is performed in accordance with the

attached installation instructions.

5.5 Use of suction unit with disposable

systems

The suction unit may also be used as a tabletop unit with

disposable systems that can be attached to a standard

rail.

5.3 Tray in foot of system trolley

(REF 340.0084.0)

A tray (available as an optional extra) may be inserted in

the foot of the trolley.

5.0 Options

5.6 Battery Backup System (Option)

A Battery Backup (UPS) may be installed on the foot of

the system trolley. Can be usefull to brige over blackout /

brownout. Installation of the board is performed in

accordance with the attached installation instructions.

Make sure to combine the ATMOS C 451 only with Medical

Grade UPS in clinical environment.

Follow the instructions of the user manual of the UPS.

Fig. 19.

Fig. 19.

!

Optionally the suction unit may also be used on the system

trolley with disposable systems that can be attached to a

standard rail.

This requires the standard rail set for installation to the

trolley in accordance with the attached instructions, and

the adapter with standard rail for installation to the securing

device of the suction unit as described in the attached

installation instructions. This seals the upper vacuum con-

nection and provides the opportunity for attaching additional

accessories on the standard rail thus available.

When using the Receptal canisters the following supports

have to be used:

2 x 1,5 l REF 444.0027.0

1 x 2 l REF 444.0030.0

2 x 2 l REF 444.0028.0

1 x 3 l REF 444.0031.0

2 x 3 l REF 444.0029.0

14

6.1 General information on cleaning and disinfection

The measures described herein regarding cleaning

and disinfection do not replace the regulations

valid for operating the device!

The information regarding concentration of

cleaning liquids and disinfectant solutions stated by

the relevant manufacturers must strictly be

observed!

6.0 Cleaning

Medical devices must always offer a maximum in safety and function.

We therefore recommend:

Prior to each application:

if

necessary

Prior to cleaning

6.2 Cleaning and sterilizing the unit

surface

Always disconnect the device from the power line,

before cleaning and disinfecting the surface.

Wipe the surface clean with a cloth soaked in a cleaning

solution or disinfectant. Liquids must not enter the device.

All of the cleaning solutions and disinfectants listed below

can be used.

Should liquids have penetrated into the device, it must

be inspected (danger of an electric shock) and the

pump must be decontaminated resp. exchanged

(infection risk).

6.3 Recommended disinfectants for instruments

Disinfectant Contents (in 100 g) Manufacturer

GIGASEPT FF neu succinic acid dialdehyde 11,0 g Schülke & Mayr, Norderstedt

(Anwendungskonzentrat) dimethoxy tetrahydrofurane 3,0 g

corrosion inhibitors non-ionic tensides

Sekusept aktiv sodiumpercarbonate, phosphonates Ecolab, Düsseldorf

non-ionic tensides

neodisher AN Phosphate > 30 g Dr. Weigert, Hamburg

non-ionic tensides < 5 g

Enzyme

Using the cleaning agent Neodisher AN (manufactured by

Dr. Weigert, Hamburg) cleaning in an automatic cleaner

and disinfecter is also possible.

Thermal disinfection is carried out at 93° C.

15

7.0 Maintenance

6.0 Cleaning

6.4 Recommended disinfectants for surfaces

Disinfectant Contents (in 100 g) Manufacturer

Mikrobac forte benzyl - C12 - C18 - alkyldimeththyl - 19,9 g Bode Chemie, Hamburg

ammoniumchloride

N- (3-Aminopropyl) - N - dodccylpropane- 1,3 - 5,0 g

diamine

Green & Clean SK alkyl-dimethyl-benzyl-ammoniumchloride < 1 g Metasys, Rum (Österreich)

(Anwendungs- dialkyl-dimethyl-ammoniumchloride

konzentrat)

Repairs

The following may require repairs from the manufacturer or an authorized service partner. Prior to sending in the device, please

contact your service partner by phone.

Liquids have penetrated the device

Sudden occurrence of unusual noises

Operational and functional disorders which cannot be resolved by means of the hints describes in the chapter

“Troubleshooting”.

Measures to be taken prior to sending in the device:

If the device has to be sent in for repair after consultation with the manufacturer or an authorized service partner, we ask you to

observe the following:

Please send in the complete device (see scope of delivery).

Please remove all disposable parts and consumables.

Thorough cleaning and disinfection

Airtight packing

Please enclose a detailed error description.

Warranty

ATMOS cannot guarantee an error-free function nor can ATMOS be held liable for damage to people or goods if

non-original ATMOS parts are used,

the information in these operating instructions are disregarded,

assembly,newinstallations,modications,extensionsandrepairsaredonebypeoplewhoarenotauthorisedbyATMOS.

Maintenance

Before putting the device into operation, visually check unit, secretion canister and power cable, accessories, connection cables

and hoses for signs of damage. Damaged cables and hoses must be replaced immediately!

However, every 2 years an inspection and a safety-related check according to EN/IEC 62353 have to be performed.

16

Visually inspect the device, jar and power cord before

each use.

The unit does not require any further maintenance.

8.0 Trouble shooting

The ATMOS C 451 was subjected to a thorough quality control before shipment. If there is, nevertheless, some malfunction,

you possibly might solve this problem yourselves if you observe the following instructions:

Problem Possible cauces Remedy

Unit does not start – Loose power plug – Check connection to supply socket

– no power voltage – Check inbuilding fuse

– Defective fuse – Replace fuse

Insufcientperformance – Leakageswithinthehosesystemorin – Checkcollectionjarlidandhose

or no suction the collection jar lid system, replace sealing ring on

collection jar lid, if necessary

–Filterisclogged – Replacelter,checkllinglevelin

(vacuumgauge indicates a vacuum) collection jar; evacuate jar, if

necessary

– Secretion or blood has been sucked in – Unit has to be returned for repair

and valve plates of the pump are

contaminated

7.1 Change fuse

Remove mains cable.

Press the spring clips of the fuse holder together on

both sides with a small screwdriver and pull out the fuse

holder.

Replace the fuse and push the holder back in until both

spring clips are locked into place.

Then reconnect mains cable.

Fuse REF 008.0749.0

7.0 Maintenance

Fig 21.

Fig 20.

T 1,6 A

17

REF

Accessories for ATMOS C 451

Standard rail set for system trolley

(instead of DDS-docking system for 2 system jars)

340.0081.0

System trolley, basic version for ATMOS C 451 340.0070.0

Potential equalization for system trolley 340.0082.0

Trolley with standard rail 320.0070.1

Trolley with standard rail for

ATMOS C 451 basic device

340.0058.0

DDS standard rail adapter 25 x 10 mm

with vacuum connection for the use of disposable

systems at the unit

340.0059.0

Quick connector for ATMOS C 451 000.0769.0

Optional foot switch for ATMOS C 451

when used as desk-top unit or with trolley

(installation is effected in factory)

340.0060.0

Holder for Battery Backup on request

Battery Backup, Medical Grade on request

9.0 Accessories, consumables and spare parts

18

Description REF

Bellows, silicone rubber................................... 000.0739.0

Fuse 230 V T 0,63 A/H .................................... 008.0634.0

Fuse 115 V T 1,25 A/H..................................... 008.0720.0

Mains cable angle-angle, 5 m.......................... 008.0818.0

Push-in foot for housing................................... 505.0337.0

Fixing screw for

system trolley (star handle) ............................. 000.0726.0

Clampingringforxingscrew ......................... 000.0727.0

Operating instructions...................................... 340.0300.B

9.0 Accessories, consumables and spare parts

19

10.0Technicalspecications

Technical data issued on: 04.07.2011

Airowrateofpump 45 l/min +3/-5 l/min

Max. vacuum -91kPa ( -910 mbar oder 682,5 mmHg)*@ NN

Vacuum readout -1...0 bar ± 16 mbar (Klasse 1,6) ø 63 mm

Additional air regulation mechanical regulating valve

Voltage 230 V~ (+/-10%) 50/60 Hz (REF 340.0300.0)

Current input (max.) max. 0,75 A bei 230 V~

Operating time > 12 h continuous operation without interruption within 24 h

Fuse T 800 mA/H for 230 V~

Heat emission max. 173 J/s

Noise level ≤48dB(A)@1m(ISO7779)beimax.Vakuum

Ambient conditions

Transport/storage

Operation

-22...+122°F

5...90 % humidity,

non-condensing air pressure 700...1060 hPa

+50...+95°F

20...80 % humidity,

non-condensing air pressure 700...1060 hPa

Dimensions HxWxD H 330 x B 240 x T 260 mm

H 1010 x B 360 x T 440 mm (with system trolley)

Weight Ca. 6,7 kg

Regular safety relevant

inspections

Every 2 years

Protection class (EN 60601-1) II

Degree of protection Typ BF

Protection category IPX 1

Classicationacc.toAnnexIXEEC

directions 93/42/EEC

IIa (acc. to EC directive 93/42 EEC)

CE marking CE 0124

Rules applied EN 60601-1: 2007

EN ISO 10079-1: 2000

UMDNS-Code 10 - 217

GMDN-Code 36777

REF 340.0300.0 230 V

* 1 bar = 750,06 mm Hg =1000 hPa / depending on ambient air pressure

20

11.3 Disposal

●The ATMOS C 451 is not comprised of any hazardous materials.

●The materials of the housing can be recycled completely.

●Prior to disposal, device and accessories must be decontaminated.

●The materials are to be separated carefully.

●Payattentiontocountry-specicregulationsfordisposal(e.g.wasteincineration).

11.0 Checking / Reprocessing / Disposal

Disposal within the EC

The suction device described above is a high-quality medical product with a long service life. After its life cycle it must

be disposed of professional. According to the EC directives (WEEE and RoHS) the device may not be disposed of in

domestic waste. Please observe existing national laws and rules for disposal of old devices.

Disposal within the Federal Republic of Germany

In the Federal Republic of Germany the law for electrical devices (ElektroG) rules the disposal of electrical devices.

Since this type of product is mainly used at home for secretion suction in the respiratory tract (after laryngectomy), it

must be assumed that those suction devices could be contaminated. Therefore, this type of device is excluded from

the law for electrical devices. In order to guarantee a proper disposal of your old device, please either pass on your old

device to your specialised dealer or send it directly to ATMOS MedizinTechnik for a professional disposal.

Prior to disposal respectively before transport the device surface must be disinfected.

11.1 Checking ATMOS suction devices

The ATMOS suction devices are maintenance-free in the case they are used according to the operating instructions. Ho-

wever, every 2 years an inspection and a safety-related check according to EN/IEC 62353 have to be performed.

Regular, thoroughly cleaning respectively the operation in line with the operating instructions are assumed.

A regular check of the condensate-controller on the rear side is necessary. Pull out the plastic plug and check the colour at

theendofthehose.Incaseofdiscolouration/depositsamaintenancemeasuremustbeperformedbyacertiedATMOS

service partner!

11.2 Reprocessing

Incasesecretionwassuckedintothedeviceitmaynotbeoperated.ItmustbesenttoanATMOScertiedservicepartner.

Handling of the suction device determines to a large extent its reliability and safety. The hygiene measures described in the

previous chapters are necessary measures for the protection of patients and users, and to maintain functional reliability.

Other manuals for C 451

2

Table of contents

Other Atmos Medical Equipment manuals

Atmos

Atmos C 051 Thorax User manual

Atmos

Atmos LC 27 User manual

Atmos

Atmos Chair M 2 User manual

Atmos

Atmos A 161 User manual

Atmos

Atmos S 61 User manual

Atmos

Atmos S 61 CORIAN integral User manual

Atmos

Atmos Record 55 User manual

Atmos

Atmos E 1 User manual

Atmos

Atmos S 201 Thorax User manual

Atmos

Atmos C 11 Systema User manual

Atmos

Atmos LC 16 User manual

Atmos

Atmos E 341 User manual

Atmos

Atmos S 201 Thorax User manual

Atmos

Atmos Chair 41 Gyne User manual

Atmos

Atmos Chair 21 P User manual

Atmos

Atmos E 2 User manual

Atmos

Atmos S 201 Thorax User manual

Atmos

Atmos LC 27 User manual

Atmos

Atmos Strobo 21 LED User manual

Atmos

Atmos C 161 User manual